A method for producing l-proline

A technology for producing proline and producing strains is applied in the field of fermentation engineering, which can solve the problems of changing the physical and chemical properties of fermentation liquid, disturbing the physiological metabolism of cells, and affecting the fermentation production of cell growth metabolism, so as to achieve the effect of eliminating the inhibitory effect and improving the yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

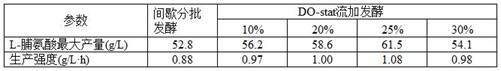

[0049] Example 1: Batch fermentation based on DO-stat fed-batch control strategy (DO controlled at 10%)

[0050] The starting condition of the fermenter is the same as that of intermittent fed-batch fermentation. When DO rises to 10%, glucose is fed, and DO-related feeding is controlled. Whenever DO is higher than 10%, it is fed for a while to maintain dissolved oxygen at About 10% (the feed liquid composition is 500g / L glucose), ferment for 58 hours, and detect the average yield and production intensity of L-proline.

[0051] The test results are: the average output of L-proline is 56.2g / L, and the production intensity is 0.97g / L·h.

Embodiment 2

[0052] Example 2: Batch fermentation based on DO-stat fed-batch control strategy (DO controlled at 20%)

[0053] The starting condition of the fermenter is the same as that of intermittent fed-batch fermentation. When DO rises to 20%, glucose is fed, and DO-related feeding is controlled. Whenever DO is higher than 20%, it is fed for a while to maintain dissolved oxygen. At about 20% (the feed liquid composition is 500g / L glucose), ferment for 58 hours, and detect the average yield and production intensity of L-proline.

[0054] The test results are: the average output of L-proline is 58.6g / L, and the production intensity is 1.00g / L·h.

Embodiment 3

[0055] Example 3: Batch fermentation based on DO-stat fed-batch control strategy (DO controlled at 25%)

[0056] The starting condition of the fermenter is the same as that of intermittent fed-batch fermentation. When the DO rises to 25%, the glucose is fed, and the DO-related feeding is controlled. Whenever the DO is higher than 30%, the fed-batch is carried out for a while to maintain the dissolved oxygen. At about 30% (the feeding liquid composition is 500g / L glucose), ferment for 57h, and detect the average yield and production intensity of L-proline.

[0057] The test results are: the average output of L-proline is 61.5g / L, and the production intensity is 1.08g / L·h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com