Ultra-light cool double-faced weft knitting fabric and production method thereof

A cool feeling and fabric technology, applied in weft knitting, textiles, papermaking, decorative textiles, etc., can solve the problems of not being able to discharge sweat to the outer layer of the fabric in time, insufficient softness, poor sweat absorption, etc., and achieve excellent instant contact Cool feeling, simple preparation process, good moisture-wicking and quick-drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

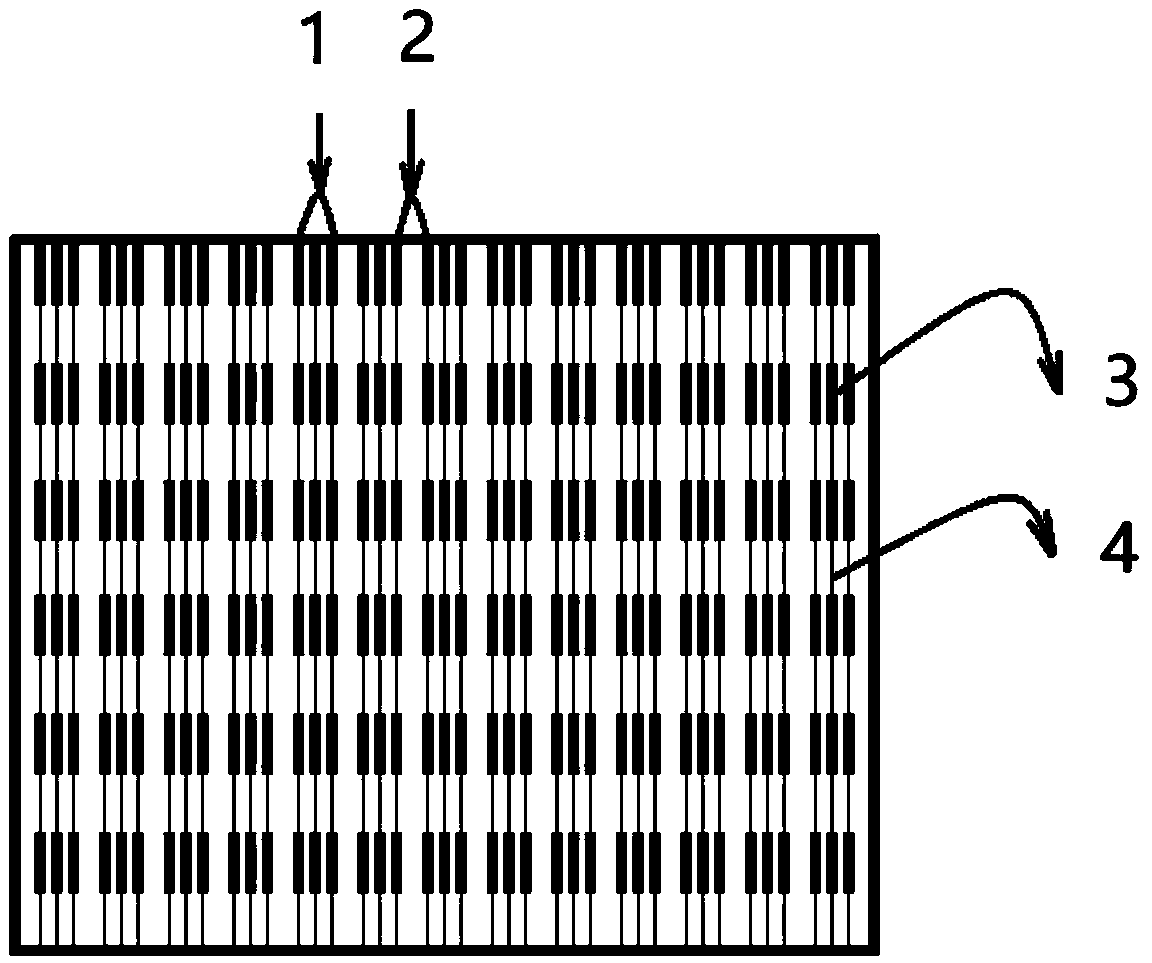

[0042] Example 1: Such as Figure 1-2 As shown, this embodiment provides an ultra-light and cool double-sided weft-knitted fabric, which is composed of 60 S Polyester cotton-like DTY yarn, 30D / 36F ultra-fine denier light network structure polyester filament and 30D / 12F cool polyester filament are interwoven. The 60 S The weight ratio of polyester imitation cotton DTY yarn, 30D / 36F ultra-fine denier light network structure polyester filament and 30D / 12F cool polyester filament is 50.5%: 17.0%: 32.5%, using the above raw materials and The weight of the yarn is only 85g / m per square meter compared to the ultra-light and cool feeling double-sided weft knitted fabric woven. 2 , Not only is it light in weight, has a double-sided appearance effect, but also has moisture-transmitting, quick-drying, moisture-absorbing and cooling functions.

[0043] In this embodiment, the ultra-light and cool double-sided weft-knitted fabric includes a fabric body with a front side and a back side. The fr...

Embodiment 2

[0050] Example 2: A method for producing an ultra-light and cool double-sided weft-knitted fabric, including a knitting and weaving process and a finishing process,

[0051] Wherein, the knitting method of the knitting and weaving process is:

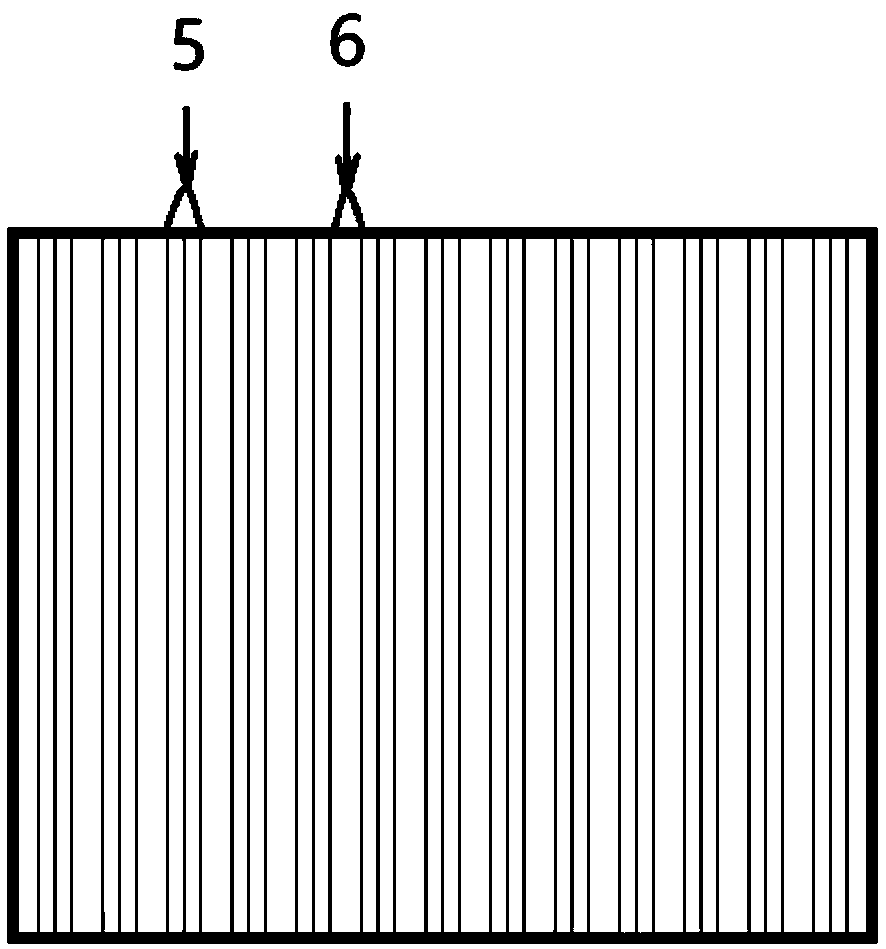

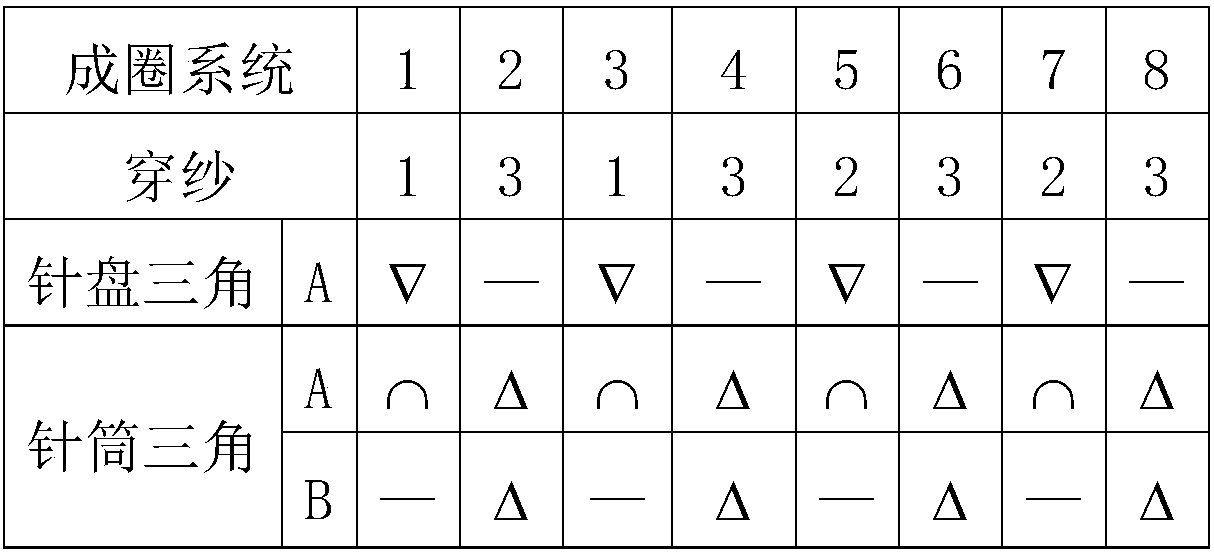

[0052] The double-sided circular weft knitting machine with the rib-type needle row configuration of the needle cylinder needle with 2 needle tracks and the dial needle with 1 needle track is used for knitting; The minimum circulation of the organization is 4 longitudinal rows×8 rows, among which: 4 longitudinal rows are arranged by 2 needle tracks, 4 syringe needles and 4 needle disc needles on one needle track, and 8 rows are formed by 8 circles around the needle barrel. The number of systems is configured, of which,

[0053] A fully organized 4 syringe needles are arranged in ABBB, and the 4 dial needles are arranged in AAAA, where A means high butt needle and B means low butt needle;

[0054] A fully organized 8-way looping system threadin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com