Cleaning and flattening device for tribute silk wadding

A technology of tribute silk and tribute silk, which is applied in the field of Gong silk cotton cleaning and flattening device, can solve the problems of inability to guarantee the cleanliness of the tribute silk cotton, complex structure, waste of water resources, etc., so as to improve the utilization rate of water circulation, improve work efficiency, and save resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

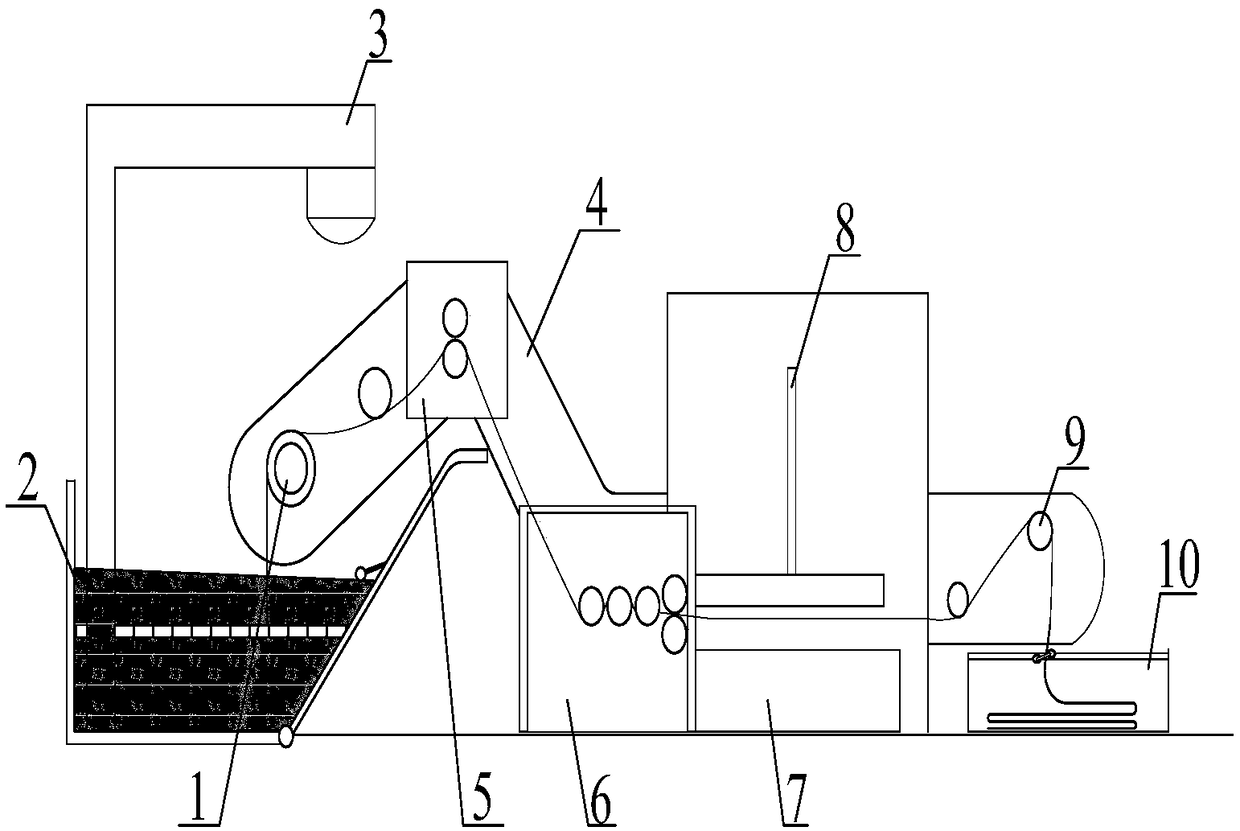

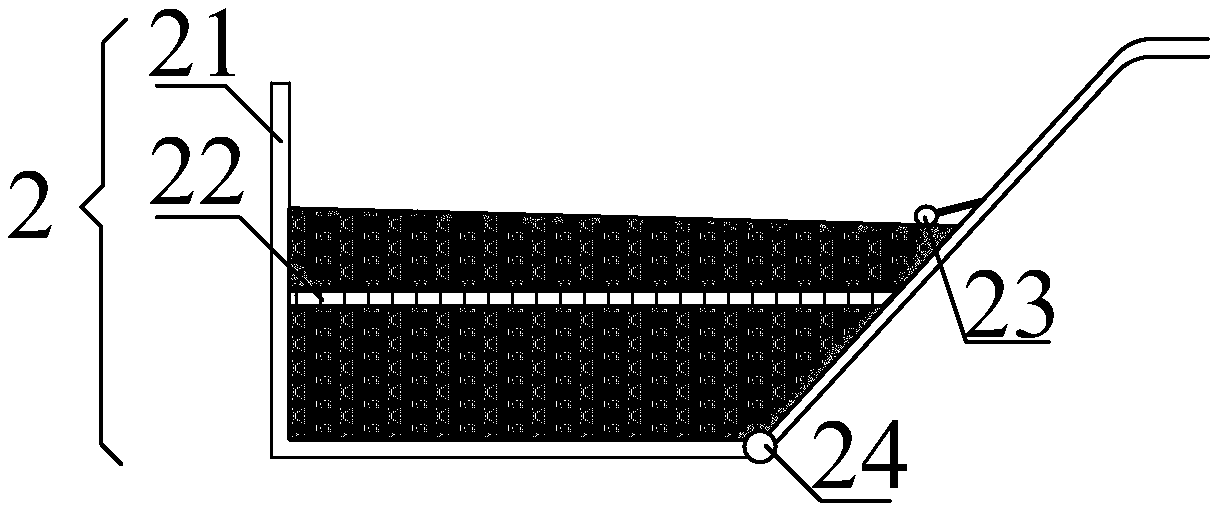

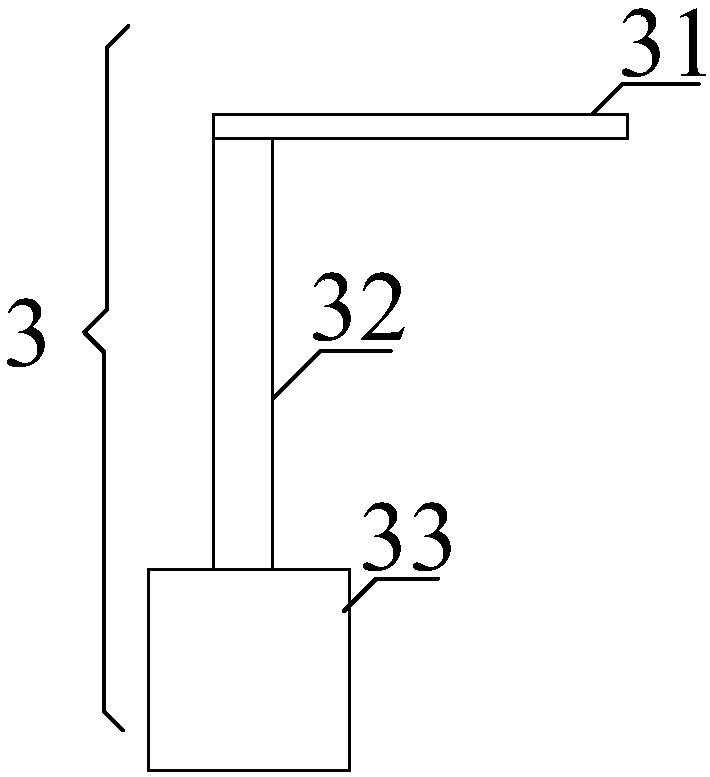

[0027] as attached figure 1 To attach Figure 7 shown

[0028] The invention provides a cleaning and flattening device for tribute silk cotton, which includes a feeding wheel 1, a water tank device 2, a flushing mechanism 3, a gear transmission mechanism 4, a draining roller 5, a drying roller group 6, a steam generator 7, and a flattening mechanism 8 , the receiving wheel 9 and the guide rod mechanism 10, the feeding wheel 1 is connected with the gear transmission mechanism 4 through gear engagement; the water tank device 2 is arranged on the left side of the drying roller group 6; the flushing mechanism 3 is welded The mode is connected on the inner wall of the water tank device 2; the draining roller 5 adopts two, and is connected with the gear transmission mechanism 4 through gear meshing; the drying roller group 6 is made up of 5-8 drying rollers 61, and through The gear meshing is connected with the gear transmission mechanism 4; the steam generator 7 is arranged under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com