Liquid weight data acquisition circuit of body cavity hyperthermal perfusion treatment machine

A data acquisition circuit and thermal perfusion technology, which is applied to weighing equipment, weighing indicating devices, and measuring devices for materials with special properties/forms, which can solve the problems of unmatched signal levels, weak output signal strength, zero Drift and other issues, achieve the effect of accurate zero and full scale values, enhance anti-interference ability, and reduce distortion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

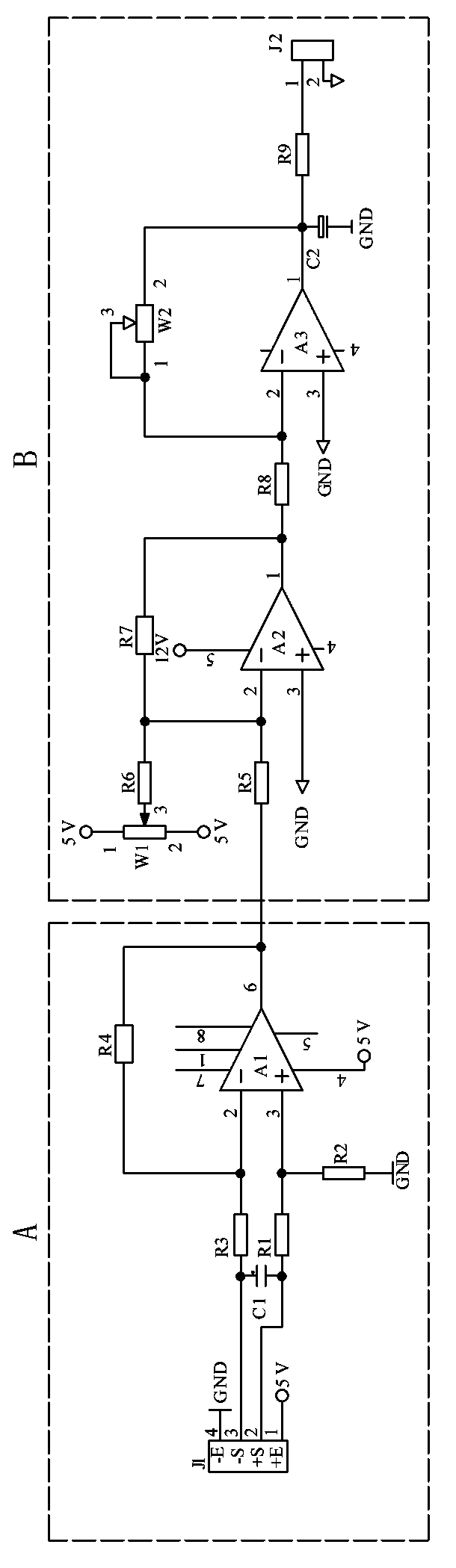

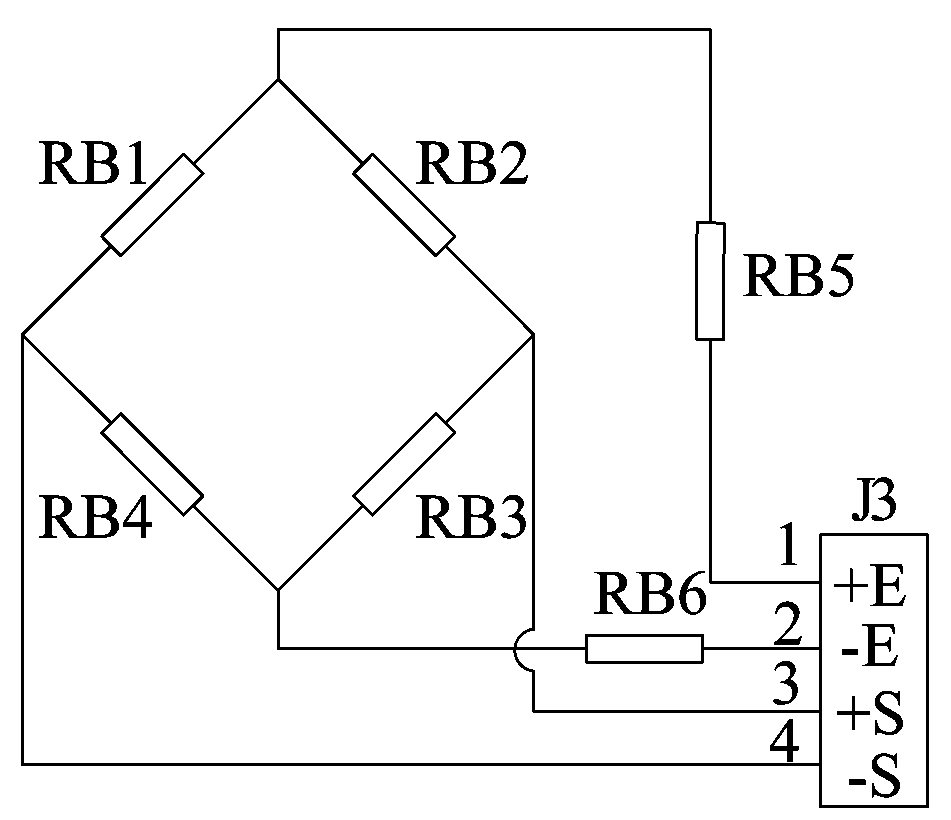

[0013] A liquid weight data acquisition circuit of a body cavity thermoperfusion treatment machine, which is composed of a weight detection circuit, a differential amplifier circuit and a level matching circuit, and the weight detection circuit, differential amplifier circuit and level matching circuit are electrically connected in sequence ( figure 1 and figure 2 Taken together is the complete circuit schematic diagram of this embodiment, for the convenience of observation, the complete circuit diagram is divided into figure 1 and figure 2 two parts).

[0014] refer to figure 2 , the weight detection circuit includes a resistor RB1, a resistor RB2, a resistor RB3, a resistor RB4, a resistor RB5, a resistor RB6 and a connector J3; one end of the resistor RB1 is divided into two paths, and one path is connected to the connector through the resistor RB5 1 pin of J3, the other way is connected to the other end of the resistor RB1 through the resistor RB2, resistor RB3 and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com