Letinus edodes coating fresh keeping agent and preparation method thereof

A technology of coating preservatives and shiitake mushrooms, which is applied in the direction of protecting fruits/vegetables with a coating protective layer, which can solve the problems of poor fresh-keeping effect and loss of nutrients, and achieve the enhancement of the ability to prevent pollution and bacterial invasion, and prevent bacterial invasion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

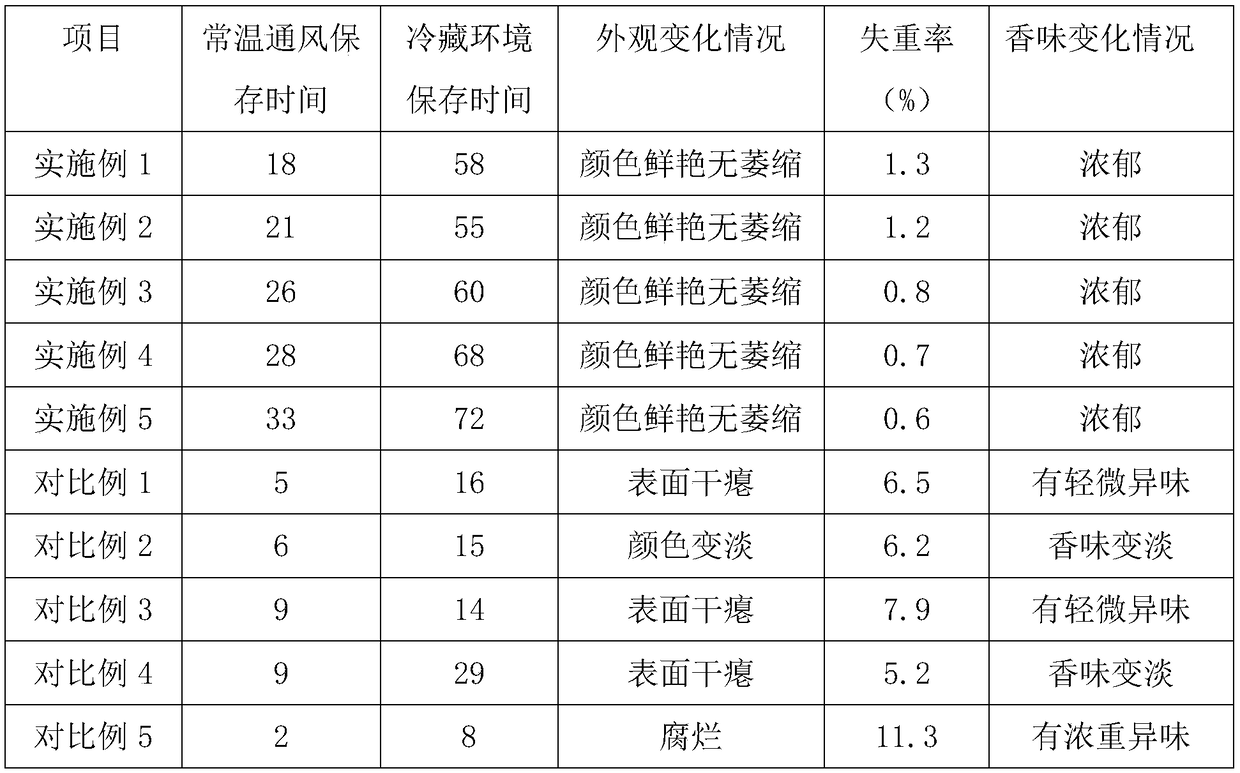

Examples

Embodiment 1

[0029] This embodiment relates to a fresh-keeping agent for shiitake mushroom coating, which is composed of the following raw materials in parts by weight: 30 parts of tea polyphenol extract, 20 parts of modified konjac starch, 10 parts of chitin, 8 parts of sodium oleate, 1 part of benzoic acid 1 part, 1 part of natamycin, 15 parts of water.

[0030] Wherein, the extraction method of tea polyphenols is as follows: take the cleaned tea leaves and put them into a ball mill, grind them to a particle size of 100 mesh, put them into an extraction device, add water 8 times the weight of tea leaves, and heat at 40°C. Ultrasonic extraction was performed for 40 minutes, and the tea polyphenol extract was obtained by filtration.

[0031] Wherein, the preparation method of modified konjac starch is: take sodium hexametaphosphate and dissolve it in water with 100 times of its weight portion, stir until sodium hexametaphosphate is completely dissolved, obtain sodium hexametaphosphate solu...

Embodiment 2

[0036] This embodiment relates to a fresh-keeping agent for mushroom coating, which is composed of the following raw materials in parts by weight: 40 parts of tea polyphenol extract, 30 parts of modified konjac starch, 18 parts of chitin, 14 parts of sodium oleate, 2 parts of benzoic acid 3 parts, 3 parts of natamycin, 23 parts of water.

[0037] Wherein, the extraction method of tea polyphenols is as follows: take the cleaned tea leaves and put them into a ball mill, grind them to a particle size of 180 mesh, put them into an extraction device, add water 10 times the weight of tea leaves, and heat at 50°C. Ultrasonic extraction was carried out for 60 minutes, and the tea polyphenol extract was obtained by filtration.

[0038] Wherein, the preparation method of modified konjac starch is: take sodium hexametaphosphate and dissolve it in water with 100 times of its weight portion, stir until sodium hexametaphosphate is completely dissolved, obtain sodium hexametaphosphate soluti...

Embodiment 3

[0043] This embodiment relates to a fresh-keeping agent for mushroom coating, which is composed of the following raw materials in parts by weight: 32 parts of tea polyphenol extract, 22 parts of modified konjac starch, 12 parts of chitin, 10 parts of sodium oleate, 1.2 parts of benzoic acid 1.2 parts of natamycin, 17 parts of water.

[0044]Wherein, the extraction method of the tea polyphenols is as follows: take the cleaned tea leaves and put them into a ball mill, grind them to a particle size of 100 mesh, put them into an extraction device, add water 8 times the weight of tea leaves, and heat at 40 °C, ultrasonically extract for 40 minutes, and filter to obtain tea polyphenol extract.

[0045] Wherein, the preparation method of the modified konjac starch is as follows: take sodium hexametaphosphate and dissolve it in water with 100 times of its weight portion, stir until sodium hexametaphosphate is completely dissolved, obtain sodium hexametaphosphate solution, and dissolve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com