Shunting extraction process for separating lithium isotope

A lithium isotope and process technology, applied in the separation of different isotopic elements, separation methods, separation of dispersed particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

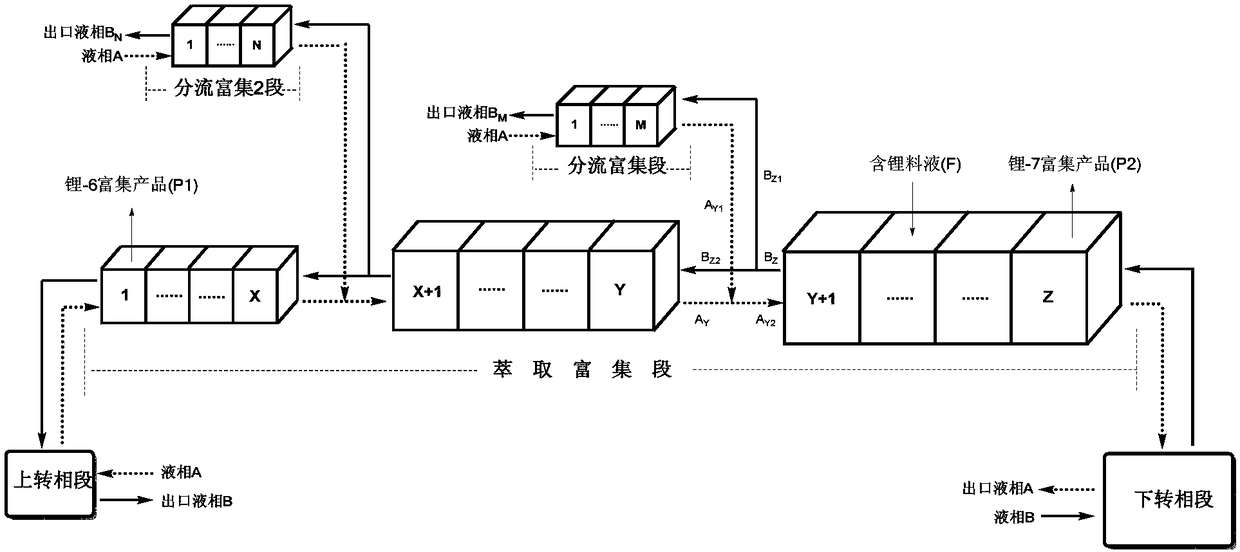

[0087] Connect the pipelines according to the process diagram. The first to 33 stages of the extraction and enrichment section adopt 33 SH-1 centrifugal extractors (rotating drum volume 0.15L), and the 34th to 68th stages adopt 35 SH-2 centrifugal extractors (rotating Drum volume 0.30L).

[0088] Lead out the split extraction section between the 33rd and 34th stages and enter the split extraction section liquid phase B Z1 The flow rate is the 34th exit B Z 45% of the flow, the remaining part of the liquid phase B Z2 Proceed to level 33. The split extraction section adopts 3 SH-1 type centrifugal extractors (rotating drum volume 0.15L).

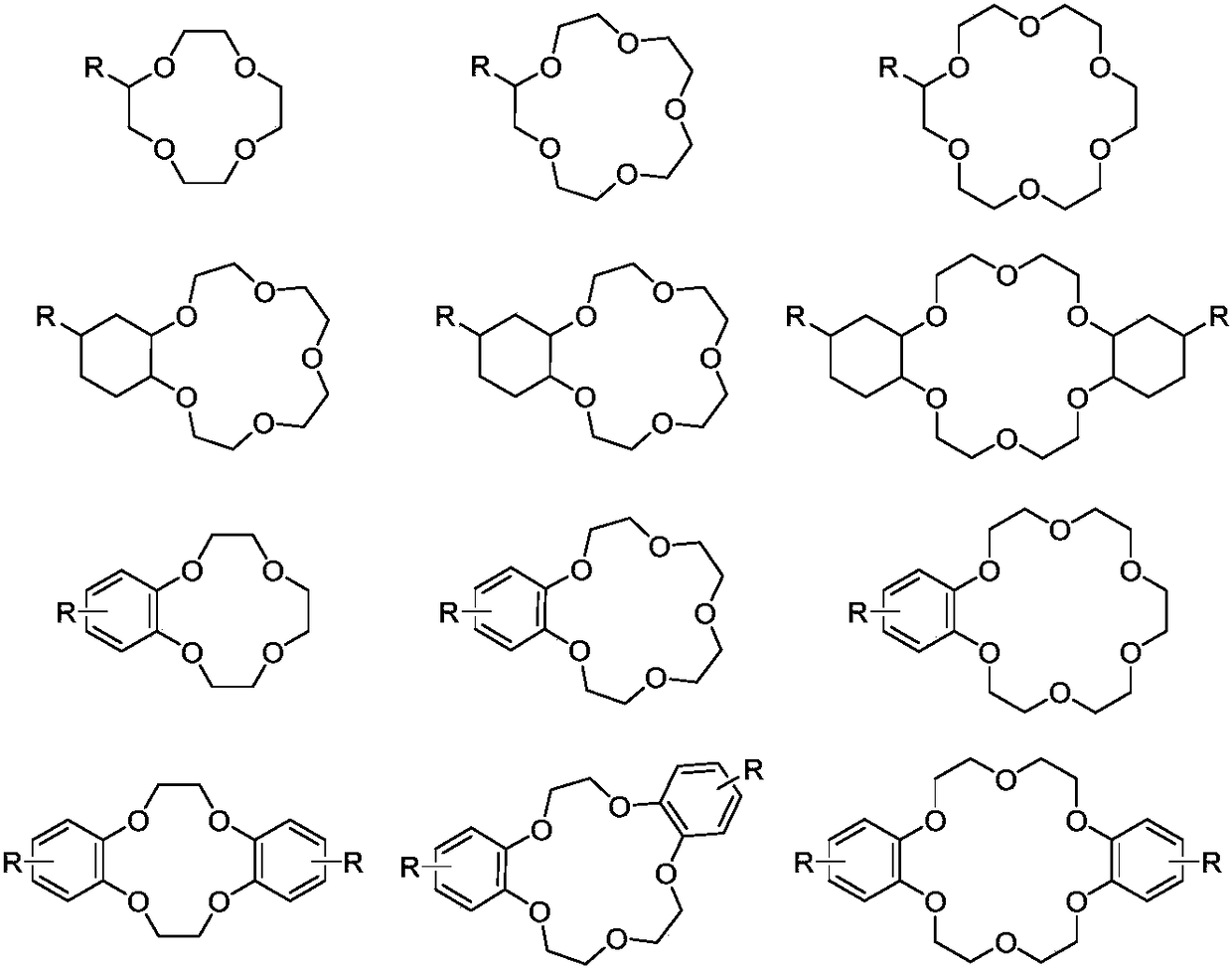

[0089] Liquid phase A is the aqueous phase; liquid phase B is the organic phase, containing the extractant as 4-tert-butylbenzo15-crown-5, and the diluent as chloroform.

[0090] Lithium-containing material liquid (F): LiClO 4 Aqueous solution, 3.5mol / L, in which the abundance of lithium-6 is 7.49% and the abundance of lithium-7 is 92.51%.

[0091] T...

Embodiment 2

[0095] Connect the pipelines according to the process diagram. The first to 55th stages of the extraction and enrichment section use 55 SH-1 centrifugal extractors (rotating drum volume 0.15L), and the 56th to 100th stages use 45 SH-2 centrifugal extractors (rotating Drum volume 0.30L).

[0096] Lead out the split extraction section between the 55th and 56th stages, and enter the split extraction section liquid phase B Z1 The flow rate is the 46th exit B Z 52% of the flow, the remaining part of the liquid phase B Z2 Proceed to level 45. The split extraction section adopts 4 SH-1 type centrifugal extractors (rotating drum volume 0.15L).

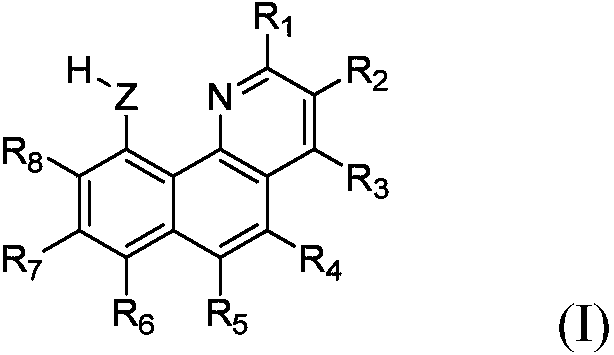

[0097] Liquid phase A is an organic phase, containing 7-trifluoromethyl-10-hydroxybenzoquinoline, as well as a co-extractant and diluent; liquid phase B is an aqueous phase, which is an aqueous NaCl solution.

[0098] Lithium-containing material liquid (F): Li 2 SO 4 Aqueous solution, 1.5mol / L, in which the abundance of lithium-6 is 7.49% and the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com