Positioning changeover device for tower crane standard mast section welding positioner

A technology of welding positioner and standard section, which is applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of increasing equipment footprint and unfavorable automatic production of products, and achieves reduced labor intensity, simple structure, The effect of reducing equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

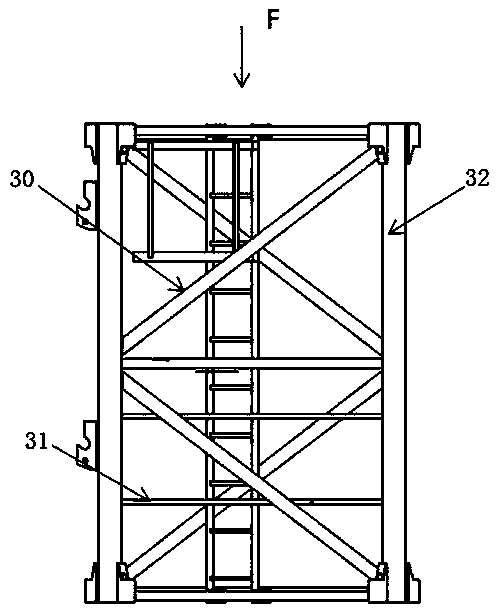

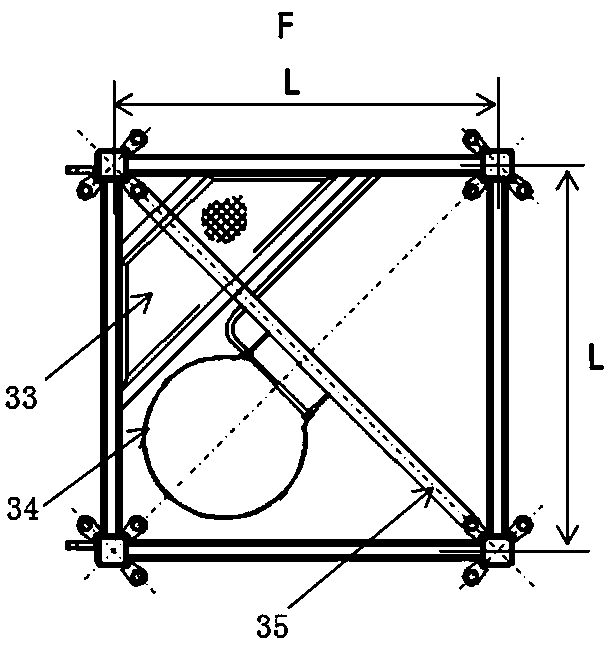

[0025] In this example, refer to the attached Figure 5 Frame 1 is the carrier of the whole set of equipment. On frame 1, four sets of chord bodies for positioning the standard section of the tower crane are respectively installed.

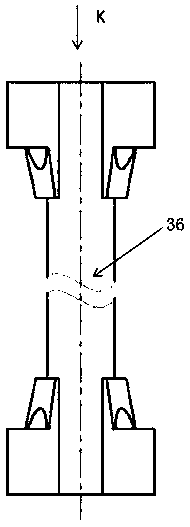

[0026] Referring to attached drawing 7, the positioning mechanism A includes end plate A4, cylindrical pin A11-1, diamond pin A12-1 and positioning plate A13-1, and one side of end plate A4 is respectively fixed cylindrical pin A11-1 and diamond pin A12-1 , the cylindrical pin A11-1 and the diamond pin A12-1 are provided with a guide sleeve 7, the guide sleeve 7 is fixed on the frame 1, and the other side of the end plate A4 forms a T with two positioning plates A13-1. Groove.

[0027] Refer to attached Figure 8 , the positioning mechanism M includes an end plate M5, a cylindrical pin M11-2, a diamond pin M12-2 and a positioning plate M13-2, the structure of the positioning mechanism M is the same as that of the positioning mechanism A, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com