Parallel compliant wheel foot device for wheeled robot

A robot and parallel technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of affecting control accuracy and stability, insufficient bearing capacity, low stiffness of foot joints, etc. Control effect, strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

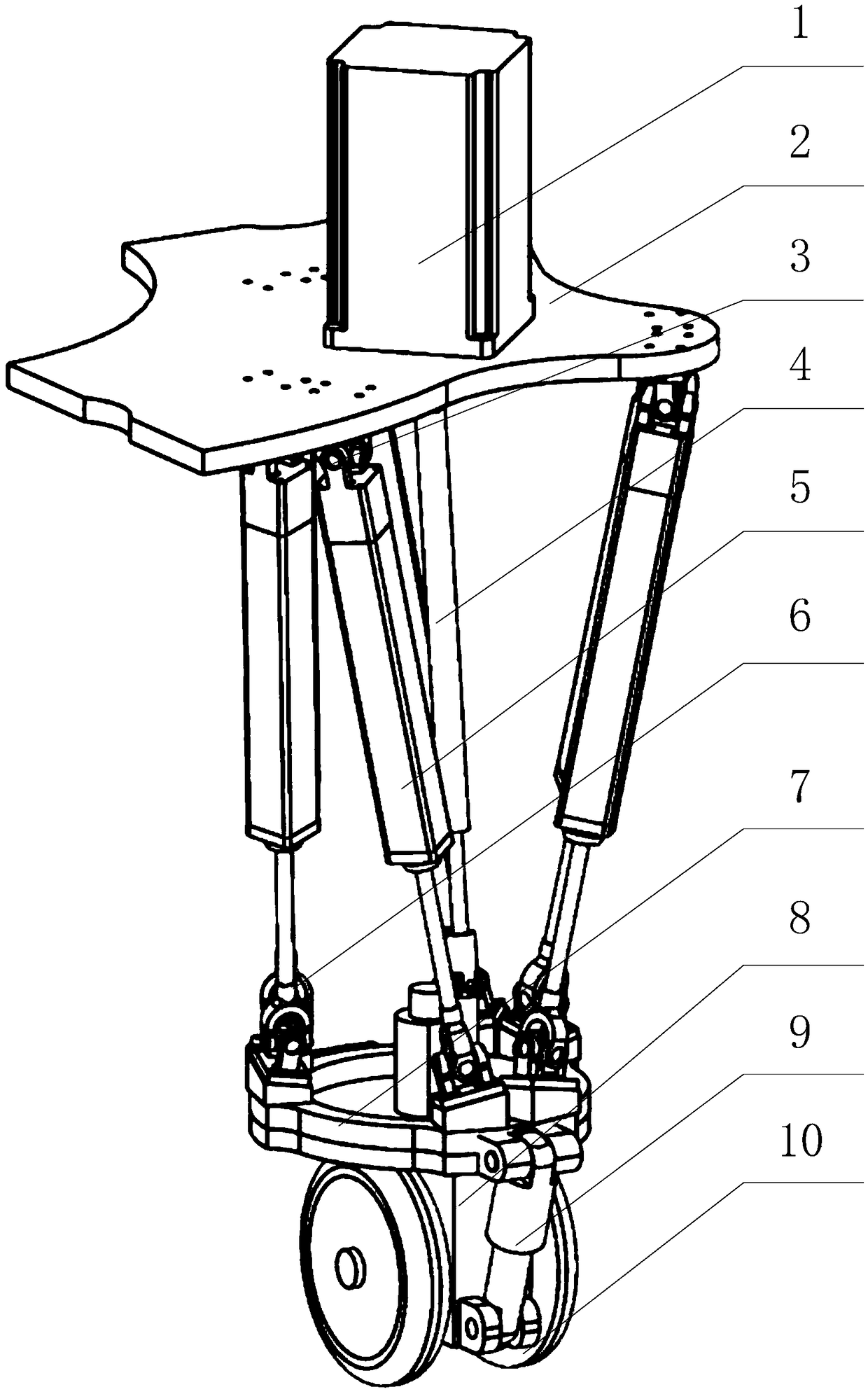

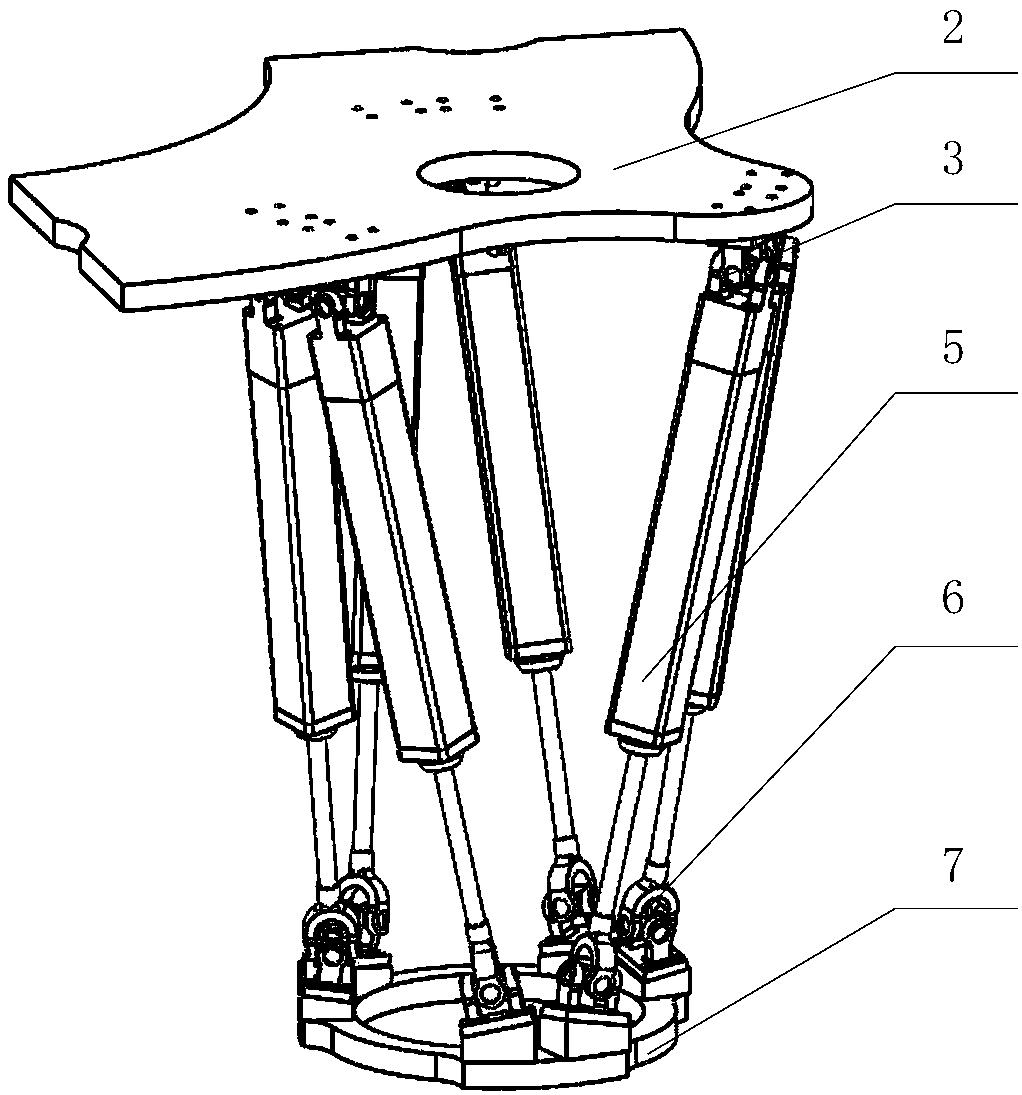

[0033] A parallel-connected compliant wheel-foot device for a wheel-footed robot is composed of an inverted parallel six-degree-of-freedom motion structure and a foot-end driving wheel assembly. The parallel six-degree-of-freedom motion structure is wrapped around the drive wheel assembly at the foot end, thereby making full use of the space and reducing the volume of the entire wheel foot device, which is suitable for small-volume applications. Moreover, through the design of single-degree-of-freedom spring-damping suspension, adjustable stiffness and damping can be added to the foot mechanism to realize the adaptability of the foot to external forces. important basis.

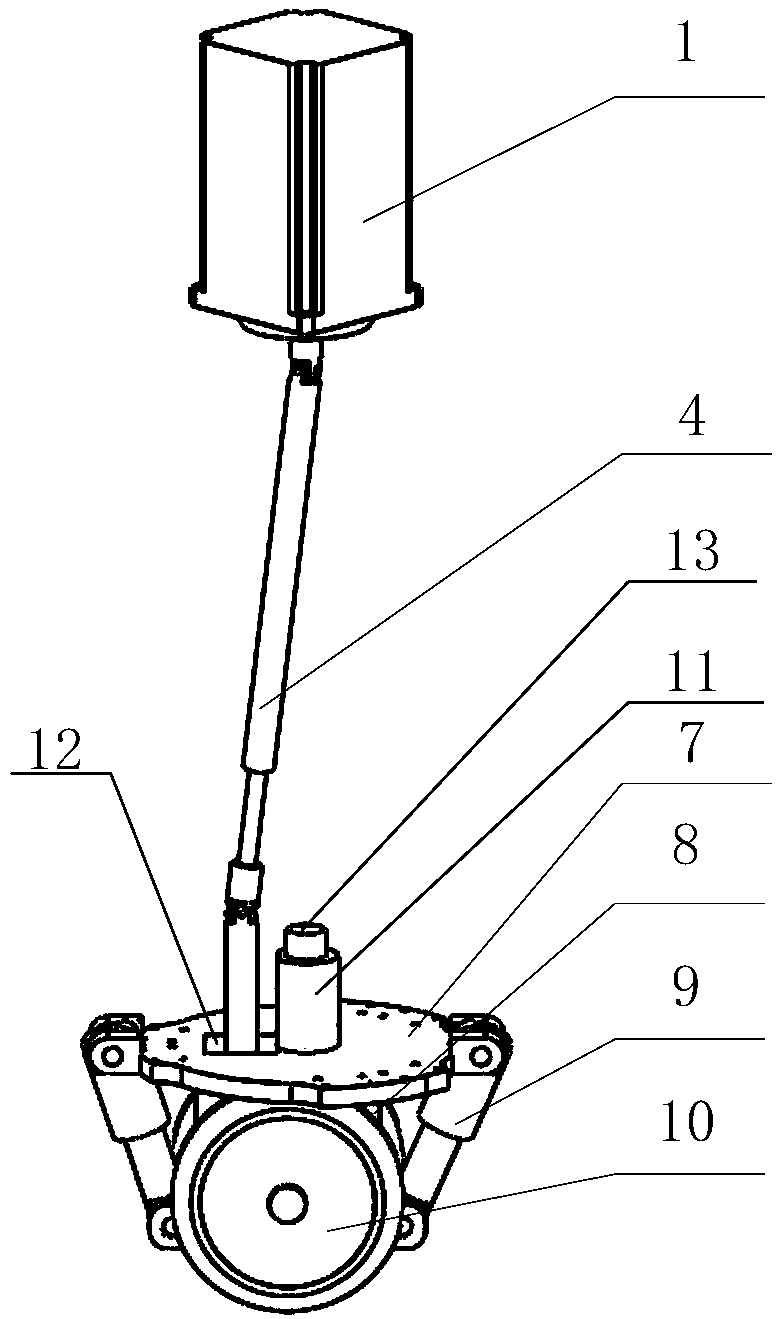

[0034] Such as image 3 As shown, the foot end drive wheel assembly includes a drive motor 1 , a transmission link 4 , a speed reducer 8 , a spring damper 9 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com