A Parallel Compliant Wheel-Foot Device for Wheel-footed Robots

A robot and parallel technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of affecting control accuracy and stability, insufficient bearing capacity, low stiffness of foot joints, etc. Control effect, strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]The present invention will be further described in further detail below with reference to the accompanying drawings.

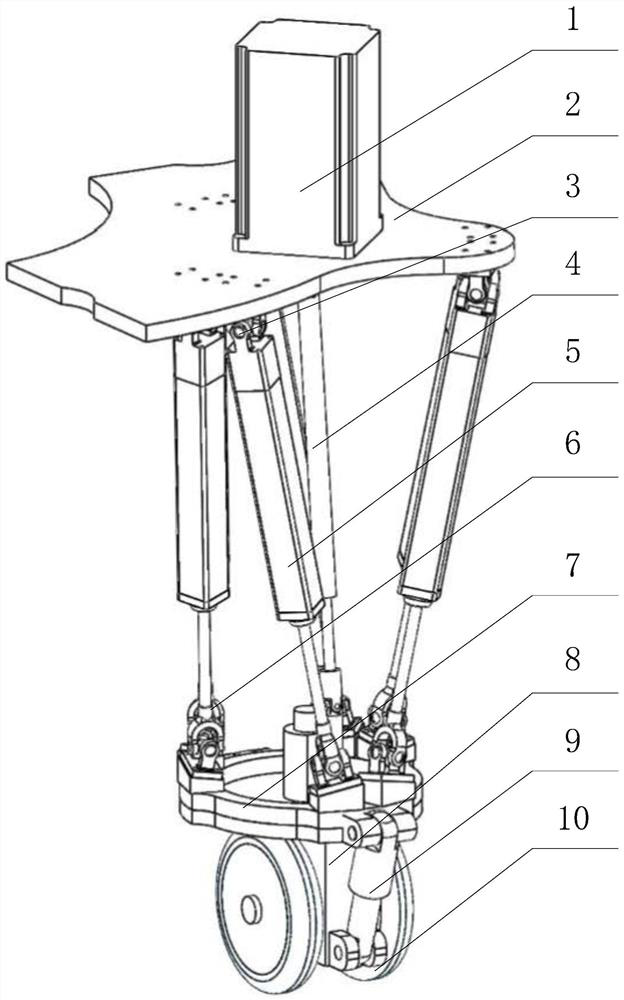

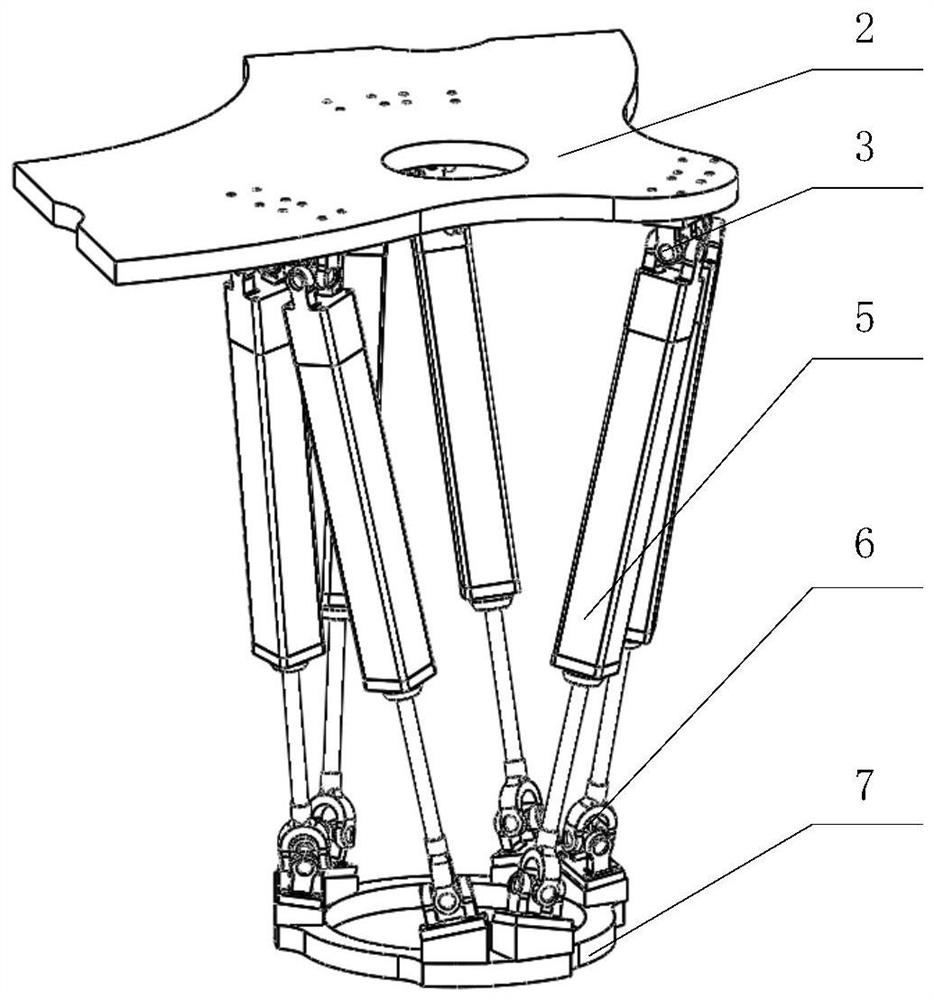

[0033]A parallel comparative pulley device for a wheelfall robot, which consists of an inverted parallel six degree of freedom motion structure and a foot-driven wheel assembly. The six-degree-of-freedom motion structure is bracketing around the foot-driven wheel assembly to make full use of space, narrowing the volume of the entire round foot device, suitable for small volume applications. Moreover, through a single free-degree spring-damping suspension design, it can be added to the foot mechanism to adjust the adjustable stiffness and damping, achieving the adaptability of the foot to the external force, is a foot-stuffed touch, and the wheel drive wheel is suspended. Important foundation.

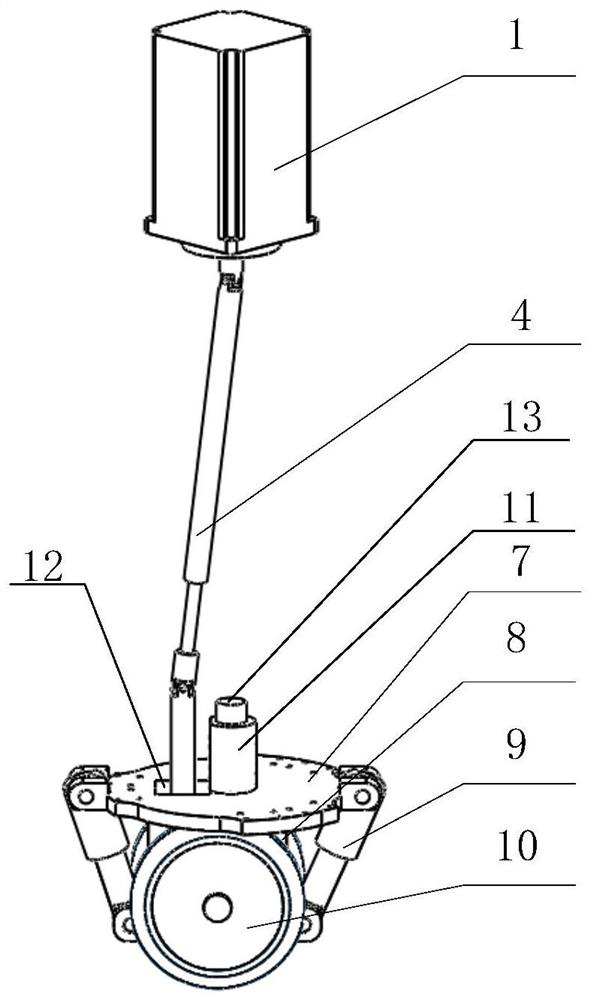

[0034]Such asimage 3 As shown, the foot-driven wheel assembly includes a drive motor 1, a transmission link 4, a reduction machine 8, a spring damper 9, and a tire 10. The dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com