A biomass rolling dehydration device

A dehydration device and biomass technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve problems such as waste of heat energy, and achieve good cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

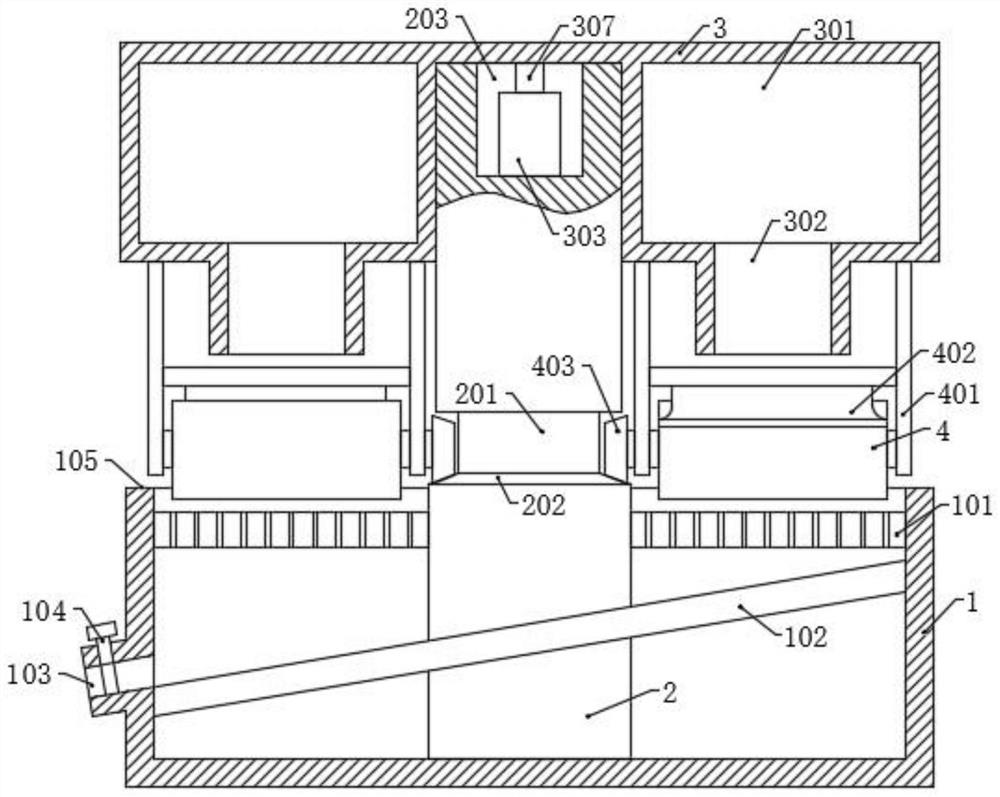

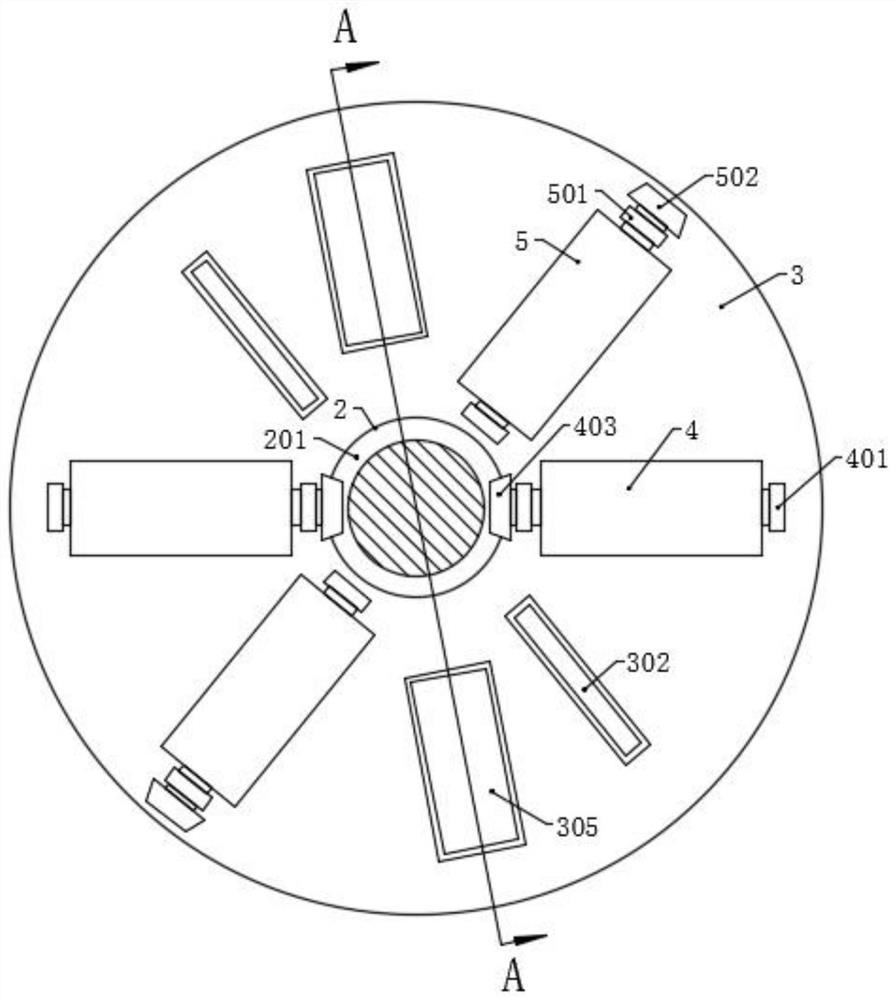

[0027] Please refer to the accompanying drawings, the present invention provides a technical solution: a biomass rolling dehydration device, including a bottom box 1, a support column 2, a rotating box 3 and a first rolling roller 4, and the bottom box 1 is provided with The water guide plate 102, the water guide plate 102 is inclined to one side, and the lower end of the water guide plate 102 on the side wall of the bottom box 1 is provided with a water outlet 103, and the water outlet 103 is provided with a liquid outlet valve 104, The upper part of the bottom box 1 is fixed with a fixed plate 101, and the fixed plate 101 is uniformly provided with permeable holes, and the bottom end of the support column 2 passes through the fixed plate 101 and is fixedly connected with the bottom surface of the bottom box 1, and an annular groove is arranged in the middle 201, the top end is rotatably connected to the top surface of the rotary box 3, the bottom surface of the annular groove...

Embodiment 2

[0031] On the basis of Embodiment 1, it also includes a second rolling roller 5, the two ends of the second rolling roller 5 are rotatably connected with a second fixed rod 501, and the top of the second fixed rod 501 is connected to the rotating box 3 The bottom surface of the bottom box 1 is fixedly connected, the outer end of the second rolling roller 5 is fixedly connected with a second bevel gear 502, and the top of the bottom box 1 is uniformly provided with first teeth 105 along the circumferential direction, and the first teeth 105 and The second bevel gear 502 meshes, and when the rotating box 3 rotates, the second bevel gear 502 meshes with the first teeth 105 on the bottom case 1 to make the second rolling roller 5 rotate around the support column 2 while rotating, and the first The rolling rollers 4 roll the biomass together.

[0032] Wherein, the distance between the bottom of the first rolling roll 4 and the fixed plate 101 is greater than the distance between th...

Embodiment 3

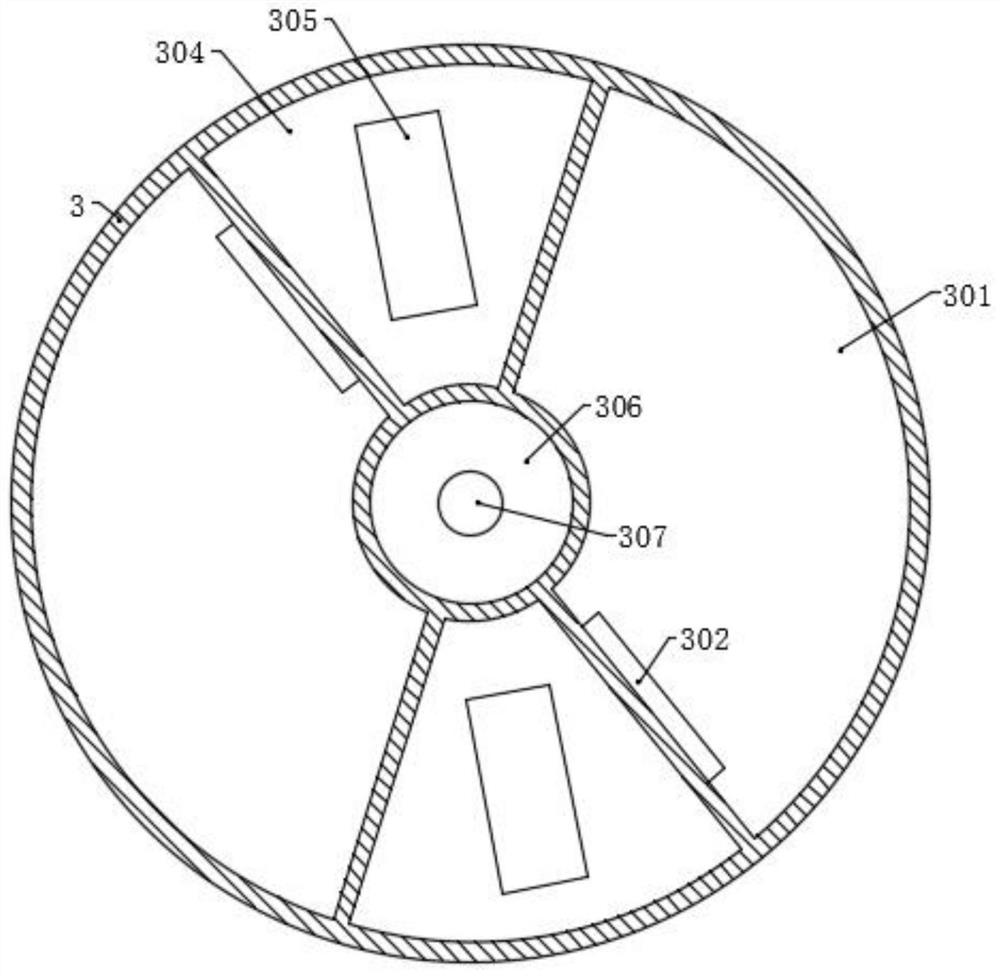

[0034]On the basis of the second embodiment, the rotating box 3 is provided with a storage chamber 301, the bottom surface of the storage chamber 301 is provided with a discharge port 302, and the rotating box 3 is also provided with a power chamber 304, the power chamber 304 The bottom surface of the bottom surface is provided with a telescopic opening 305, and a cleaning mechanism 6 is provided in the power chamber 304. The opposite direction is arranged in turn, and the biomass is added through the outlet 302 box fixed plate 101, and then rolled by the first rolling roller 4 and the second rolling roller 5 in turn, after the rolling, the biomass is removed from the fixed plate 101 Remove, and then further clean up the residual biomass on the fixed plate 101 by the cleaning mechanism 6 .

[0035] Wherein, the cleaning mechanism 6 includes a moving plate 603 and a cleaning scraper 601, two connecting rods 602 are symmetrically fixed on the bottom surface of the moving plate 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com