Method and device for producing trichlorosilane and method for producing polycrystalline silicon

A technology of trichlorosilane and chlorosilane, which is applied in the field of polysilicon production, can solve the problems of improvement, polysilicon quality reduction, resource waste cost, etc., and achieve the effect of improving quality, improving utilization rate, and being suitable for large-scale promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: Trichlorosilane is produced using the trichlorosilane production equipment of the present invention.

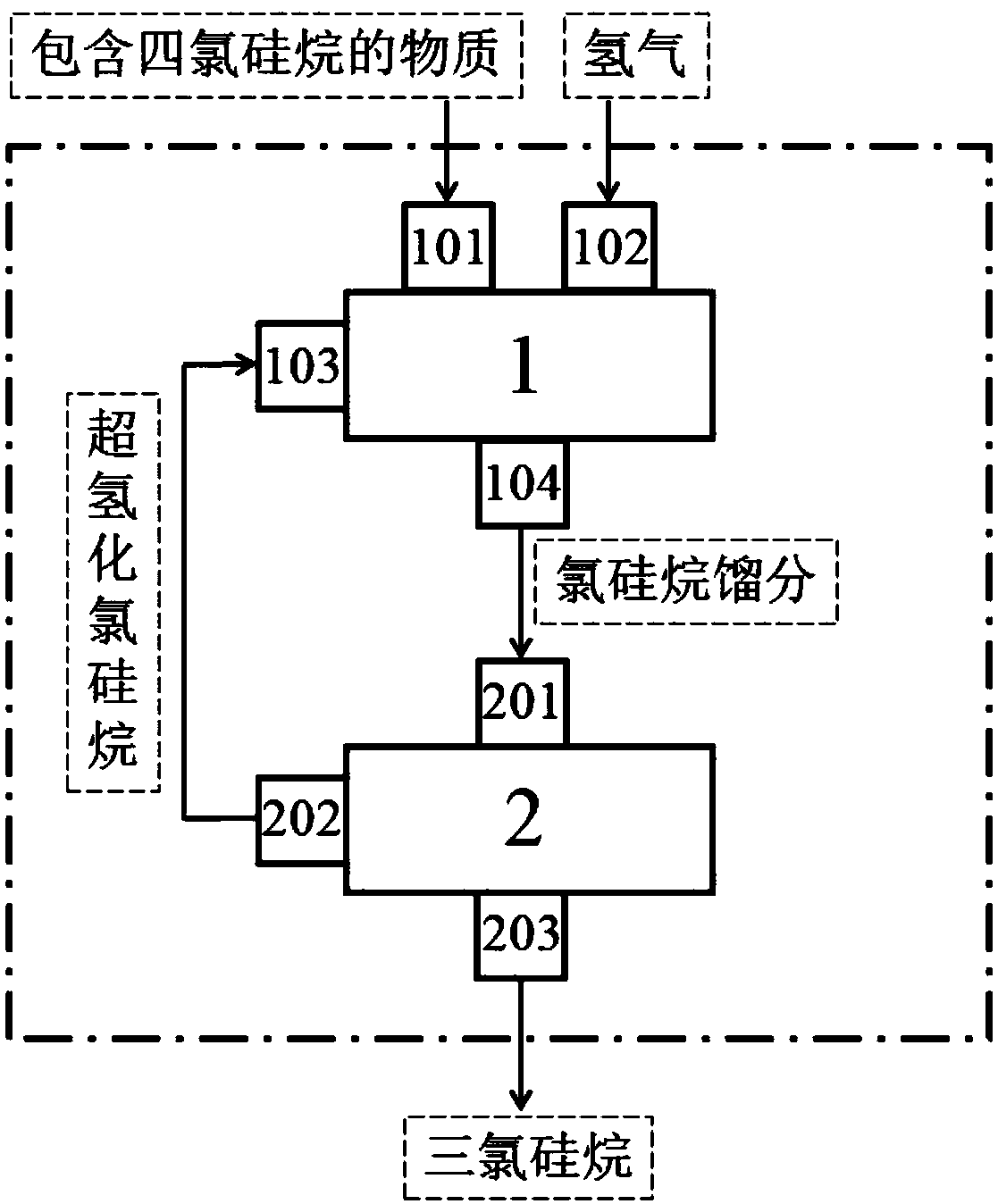

[0037] figure 1A schematic diagram of the process and apparatus of the present invention for the production of trichlorosilane is shown. The method for producing trichlorosilane comprises the following steps: 1) Hydrogenation step: the substance containing tetrachlorosilane and hydrogen are respectively introduced into the hydrogenation reaction vessel 1 through the substance inlet 101 containing tetrachlorosilane and the hydrogen gas inlet 102, and the 2) Separation step: the derived chlorosilane fraction is introduced into the fractionation tower 2 through the chlorosilane fraction inlet 201, and is subjected to fractionation , to obtain trichlorosilane and a mixed fraction containing chlorosuperhydrosilane, and trichlorosilane is exported through a trichlorosilane outlet 203; 3) circulation step: the mixed fraction containing chlorosuperhydrosilane ob...

Embodiment 2

[0038] Embodiment 2: The improved trichlorosilane production equipment of the present invention is used to produce trichlorosilane.

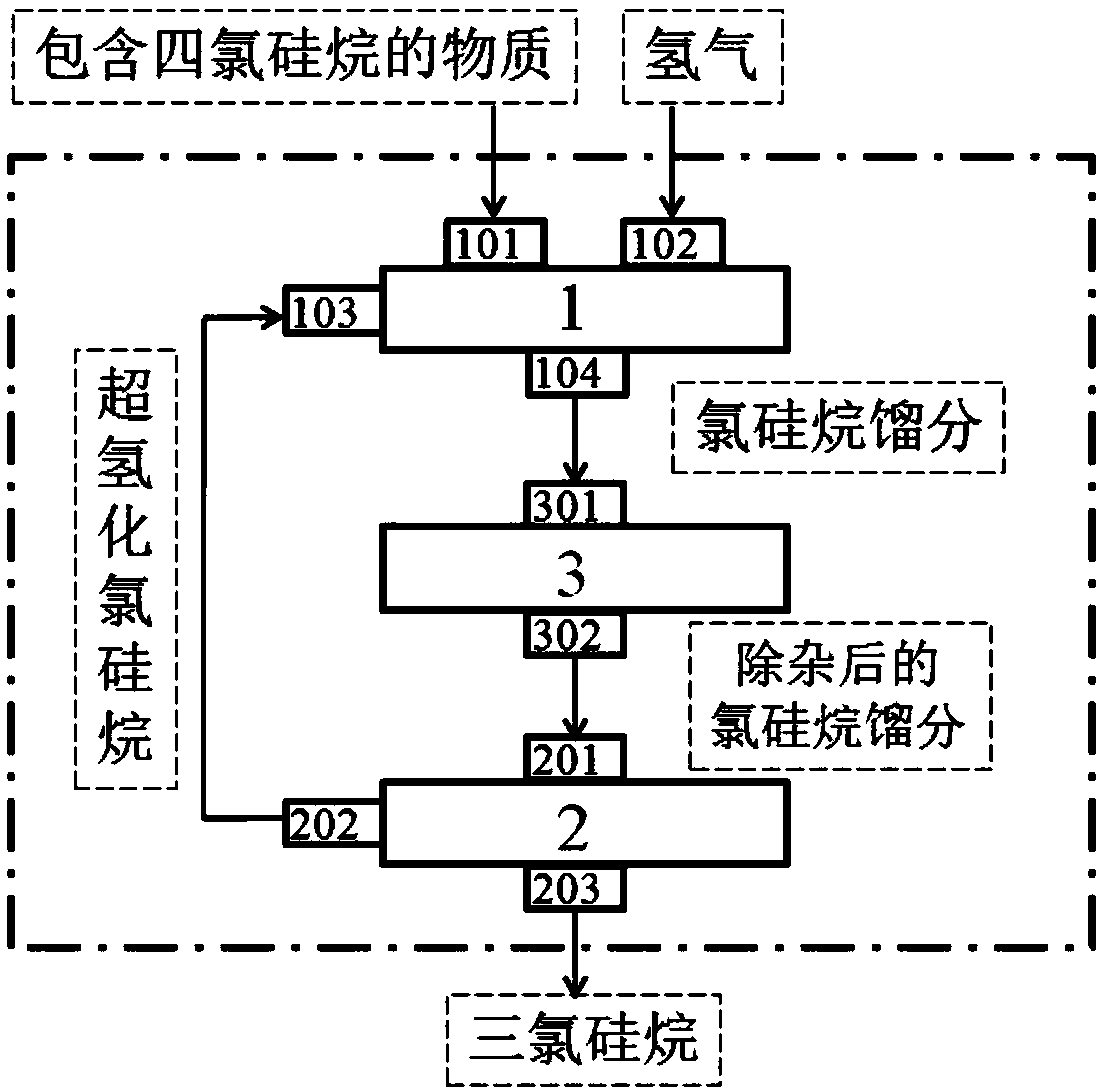

[0039] figure 2 A schematic diagram showing the improved method and the improved apparatus of the present invention for the production of trichlorosilane. The method for producing trichlorosilane comprises the following steps: 1) Hydrogenation step: the substance containing tetrachlorosilane and hydrogen are respectively introduced into the hydrogenation reaction vessel 1 through the substance inlet 101 containing tetrachlorosilane and the hydrogen gas inlet 102, and the Hydrogenation reaction to obtain a chlorosilane fraction comprising trichlorosilane and superhydrochlorosilane, and lead through the chlorosilane fraction 104; 2) impurity removal step: the derived chlorosilane fraction is introduced into the impurity removal device 3 through the chlorosilane fraction inlet 301, After impurity removal (realized by the chemical reaction of form...

Embodiment 3

[0040] Example 3: Production of high-purity trichlorosilane and high-quality polysilicon using the improved trichlorosilane production equipment of the present invention.

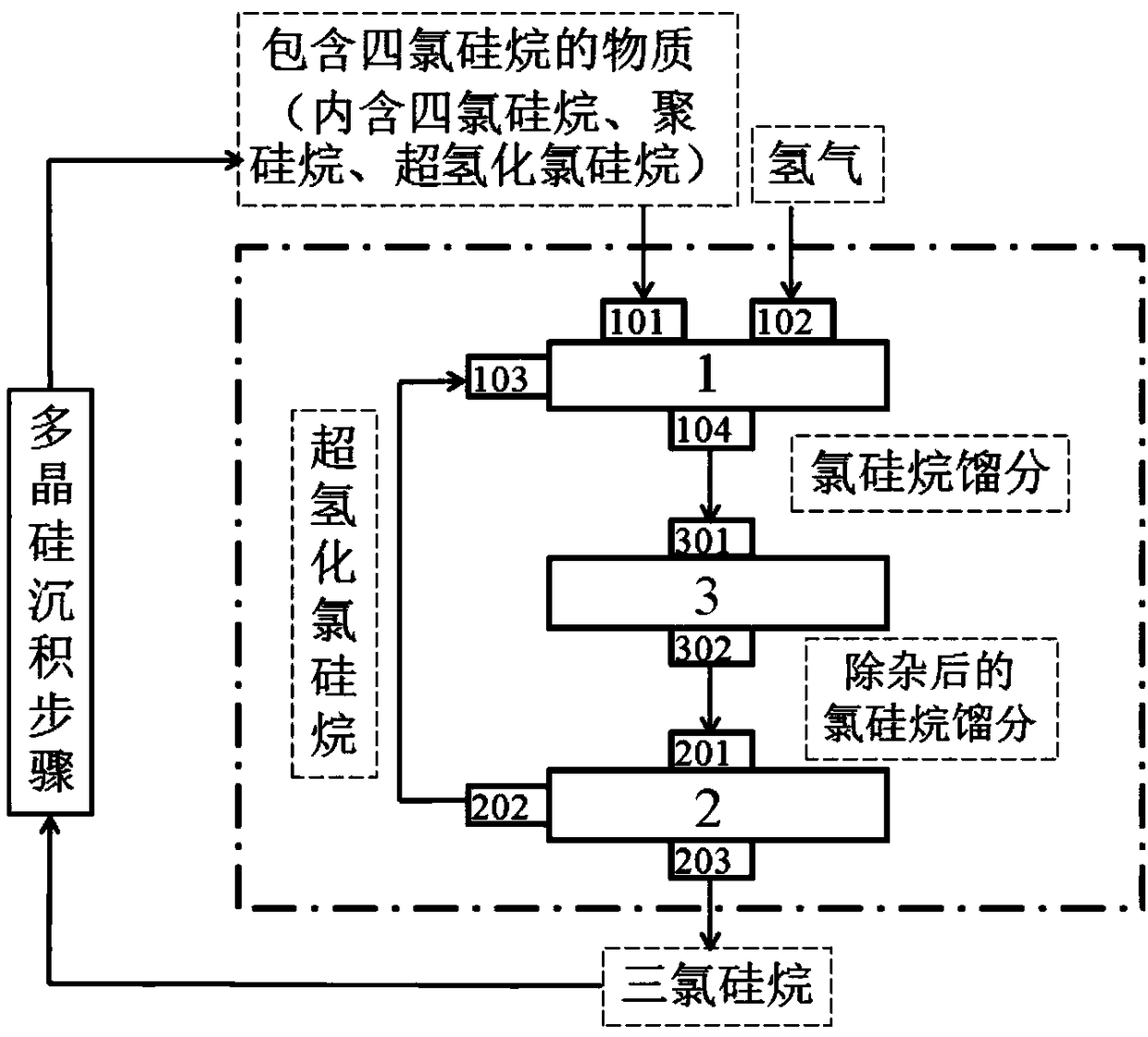

[0041] image 3 A schematic diagram showing the method of the present invention for the production of polysilicon is figure 2 Extended application of trichlorosilane production method in China. The method for producing polysilicon comprises the following steps: 1) Hydrogenation step: the substance containing tetrachlorosilane and hydrogen gas are respectively introduced into the hydrogenation reaction vessel 1 through the substance inlet 101 and the hydrogen gas inlet 102 containing tetrachlorosilane, and hydrogenated at 600-1200° C. reaction to obtain a chlorosilane fraction containing trichlorosilane and chlorosilane superhydrogen, and export it through the chlorosilane fraction 104; impurity (by forming the chemical reaction of Si-O-B chemical bond or Si-O-P chemical bond), obtain the chlorosilane fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com