High-performance tungsten oxide nanometer powder as well as preparation method and application thereof

A nano-powder, tungsten oxide technology, applied in tungsten oxide/tungsten hydroxide, nanotechnology, nanotechnology and other directions to achieve the effect of improving dimming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Measure 60ml of 1.5mol / l ammonium tungstate aqueous solution and stir until completely dissolved. Add 10ml of 0.5mol oxalic acid solution, then slowly add hydrochloric acid dropwise while stirring to adjust the pH value to 1, and stir for half an hour until the hexavalent tungsten precursor solution is obtained; take 50ml of the precursor solution and add it to the reaction kettle, and transfer it to the hydrothermal furnace , set the temperature at 120°C, and keep it warm for 30 hours; after the hydrothermal reaction, let it cool naturally, turn on the hydrothermal furnace, and wash and filter the reaction mother liquor of tungsten oxide self-coated nanopowder several times until the surface of the powder is acidic. The substance was washed clean, transferred to a drying oven, and dried at 80°C for 8h. The sample is named S2.

[0074] The properties of the obtained oxygen-deficient tungsten oxide nanopowders were characterized by XRD, TEM and spectrophotometer.

[00...

Embodiment 2

[0080] Measure 60ml of 1.5mol / l ammonium tungstate aqueous solution and stir until completely dissolved. Add 20ml of 0.5mol oxalic acid solution, then slowly add hydrochloric acid dropwise while stirring to adjust the pH value to 1, and stir for half an hour until the hexavalent tungsten precursor solution is obtained; take 50ml of the precursor solution and add it to the reaction kettle, and transfer it to the hydrothermal furnace , set the temperature at 120°C, and keep it warm for 30 hours; after the hydrothermal reaction, let it cool naturally, turn on the hydrothermal furnace, and wash and filter the reaction mother liquor of tungsten oxide self-coated nanopowder several times until the surface of the powder is acidic. The substance was washed clean, transferred to a drying oven, and dried at 80°C for 8h. The sample is named S3.

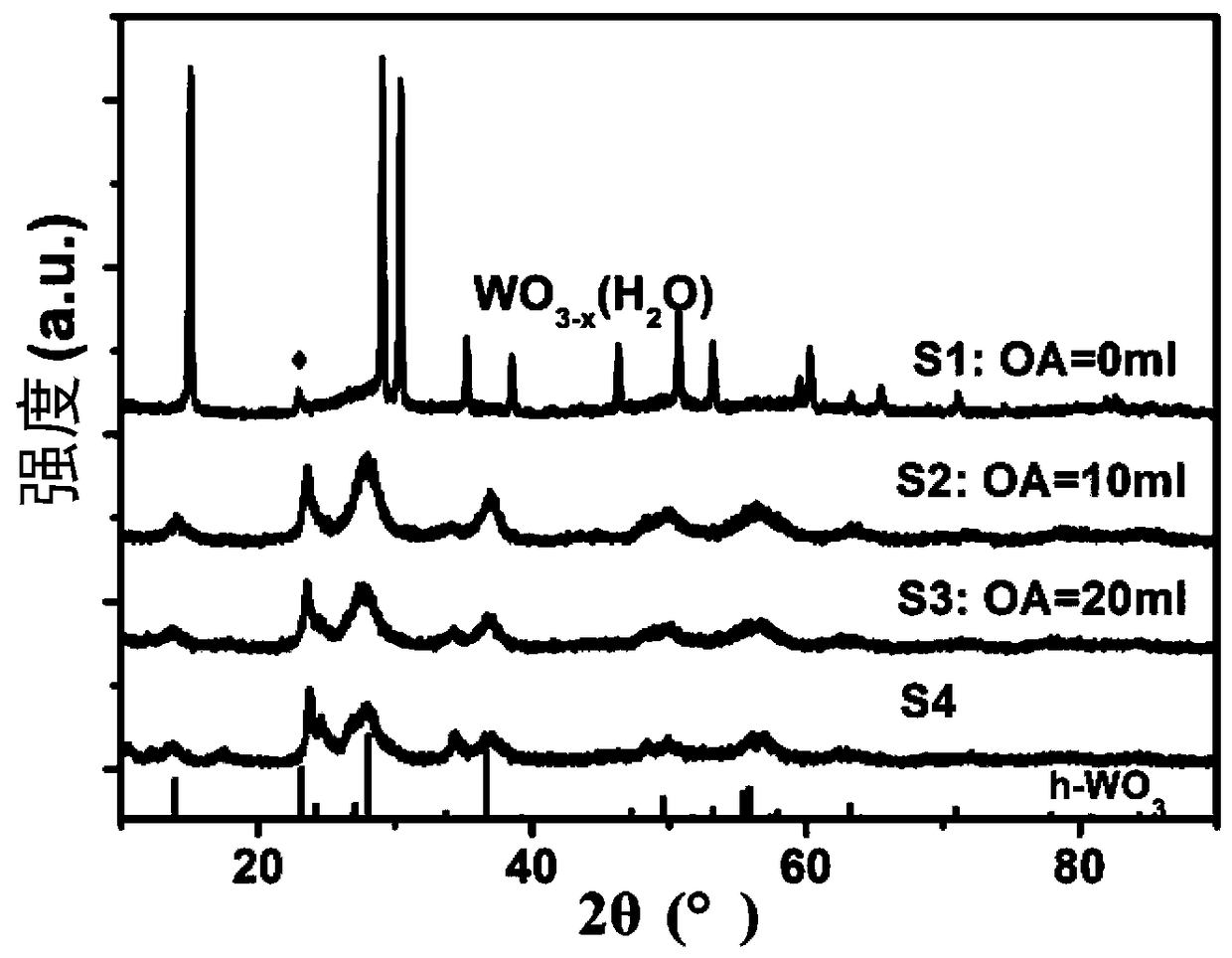

[0081] See figure 1 , From the XRD spectrum, it can be seen that the obtained tungsten oxide nanopowder is the same as that of Example 1, whi...

Embodiment 3

[0084] Weigh 25ml of 1.5mol / l ammonium tungstate aqueous solution, add 20ml of 0.5mol oxalic acid solution, and stir for half an hour until the hexavalent tungsten precursor solution (its pH value is <1); take 50ml of the precursor solution and add it to the reaction kettle , transferred to a hydrothermal furnace, set the temperature at 120 ° C, and kept it warm for 30 hours; after the hydrothermal reaction was completed, let it cool naturally, turned on the hydrothermal furnace, and washed and filtered the reaction mother liquor of the tungsten oxide self-coated nanopowder several times , until the surface of the powder is washed with acid substances, transferred to a drying oven, and dried at 80°C for 8 hours. The sample is named S4.

[0085] See figure 1 , from the XRD spectrum, it can be seen that the obtained tungsten oxide nanopowder is hexagonal phase tungsten oxide.

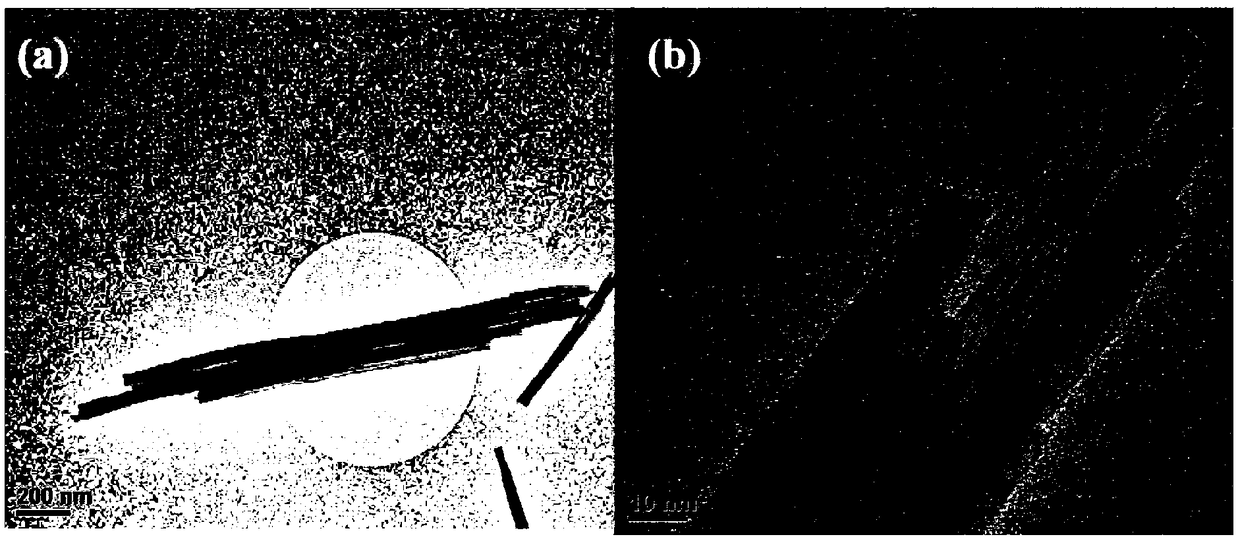

[0086] See Image 6 , from the TEM picture, it shows that the obtained tungsten oxide nanopowder is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com