Substrate material for electronic cigarette atomizer heating module and preparation method of substrate material

An electronic cigarette atomizer and basic material technology, applied in the field of electronic cigarettes, can solve the problems of increased volume of electronic cigarettes, low atomization efficiency, poor thermal conductivity of porous ceramics, etc., so as to increase user experience, improve atomization efficiency, and thermal conductivity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In parts by weight, weigh 90 parts of alumina, 5 parts of calcium titanate, 2 parts of calcium oxide, 0.5 parts of dispersant, 1 part of binder and 0.5 parts of plasticizer, and then add 40 parts of water , mixed evenly, molded, sintered at 1200°C, and kept warm for 1 hour after sintering to obtain the substrate material.

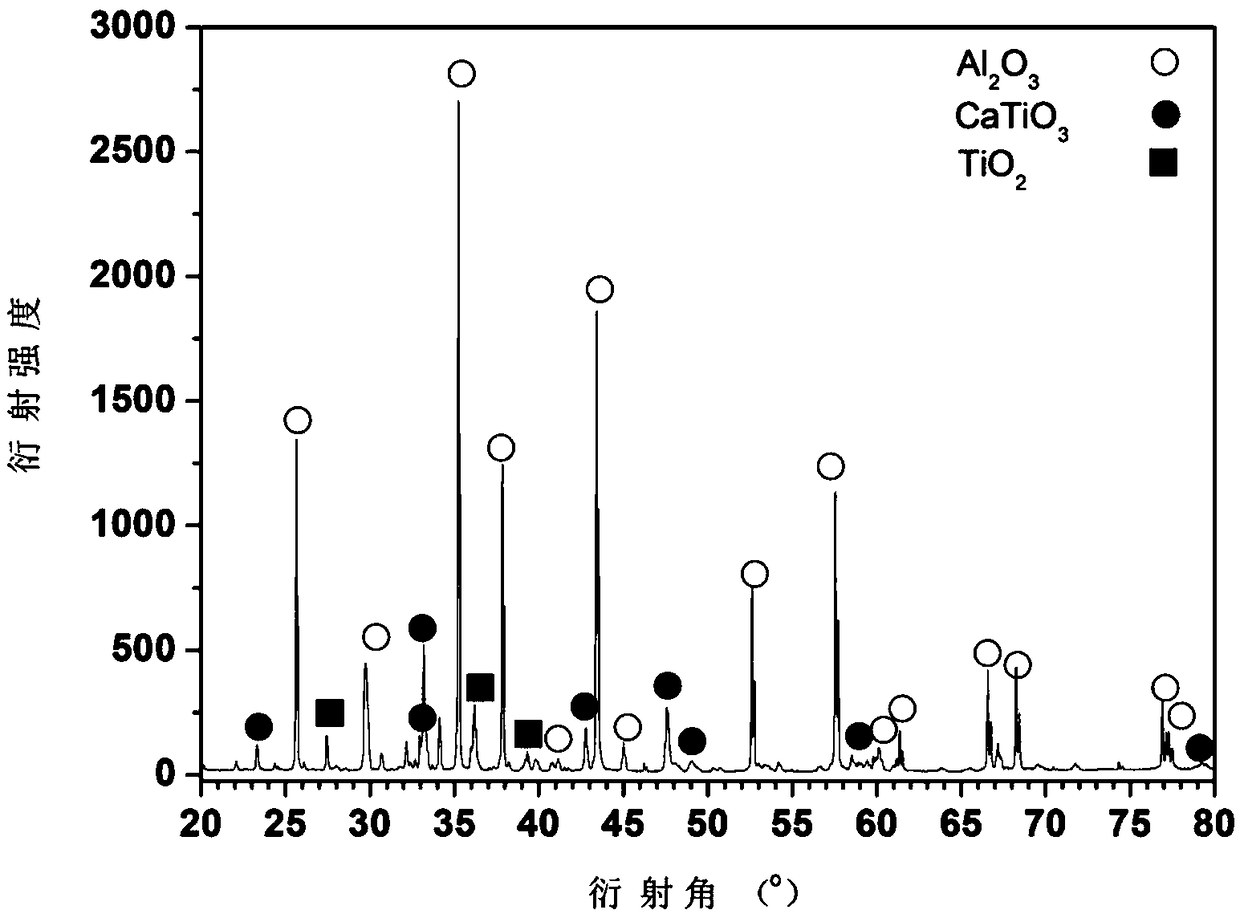

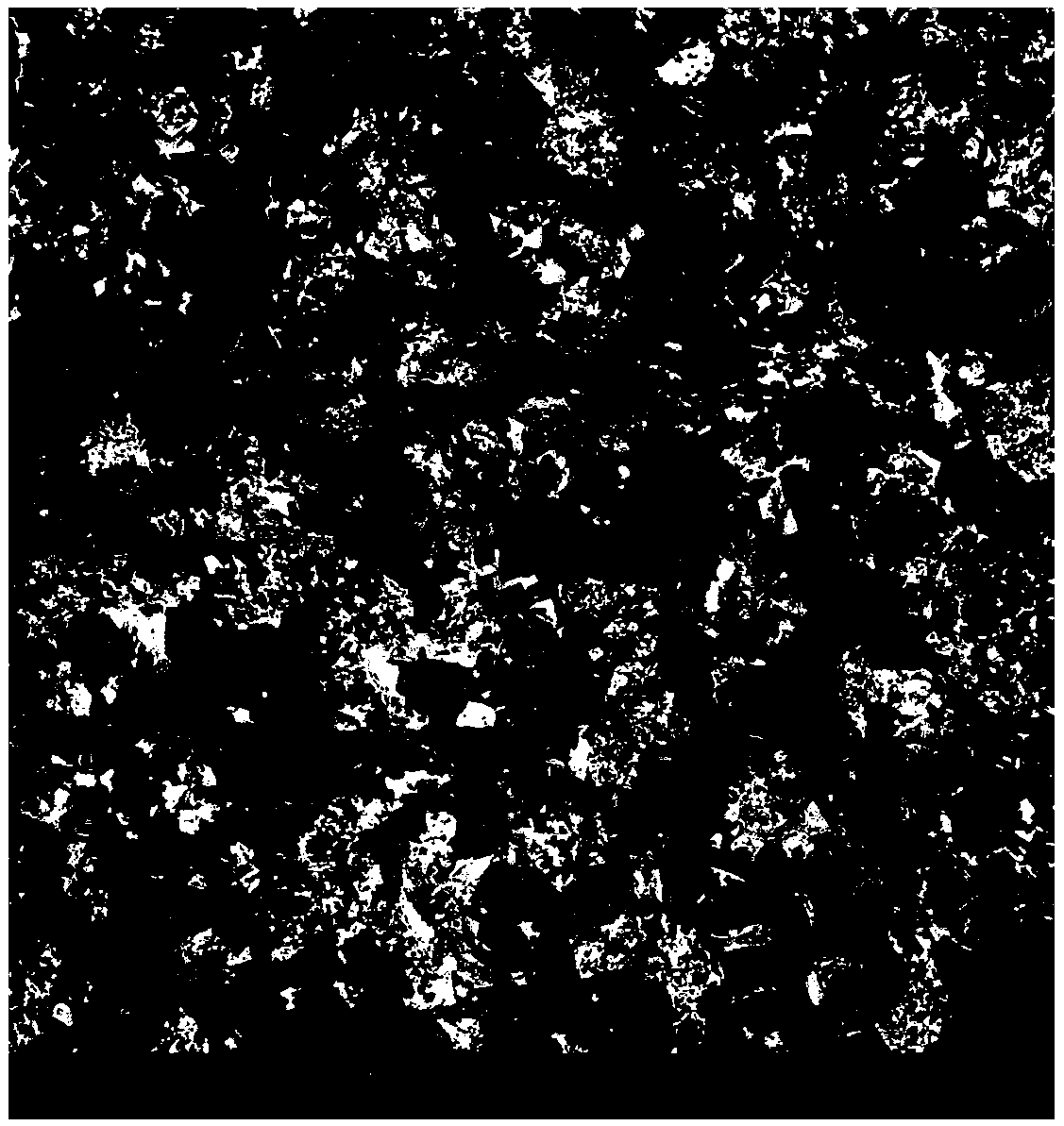

[0021] Carry out X-ray scanning to the substrate material that prepares, the result sees figure 1 . In addition, electron microscope scanning was carried out on the substrate material, and it was found that there were many micropores on the substrate material.

Embodiment 2

[0023] In parts by weight, weigh 91 parts of alumina, 6 parts of calcium titanate, 3 parts of calcium oxide, 0.5 parts of dispersant, 1 part of binder and 0.5 parts of plasticizer, and then add 40 parts of water , mixed evenly, molded, sintered at 1200°C, and kept warm for 1 hour after sintering to obtain the substrate material.

Embodiment 3

[0025] In parts by weight, weigh 92 parts of alumina, 7 parts of calcium titanate, 4 parts of calcium oxide, 0.5 parts of dispersant, 1 part of binder and 0.5 parts of plasticizer, and then add 40 parts of water , mixed evenly, molded, sintered at 1200°C, and kept warm for 1 hour after sintering to obtain the substrate material.

[0026] The substrate material prepared in Example 1 was prepared into a heating module of an electronic cigarette device, and then assembled into an electronic cigarette, compared with commercially available electronic cigarettes, and the atomization efficiency was tested, and it was found that the electronic cigarette prepared by using the substrate material in Example 1 The atomization efficiency is relatively high, reaching 14.5%, while the atomization efficiency of commercially available electronic cigarettes is only 11.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com