Heavy metal contaminated soil remediation agent and preparation method thereof

A technology for contaminated soil and heavy metals, applied in the field of soil remediation, can solve problems such as refractory degradation, difficult natural discharge or complete removal, and hazards, and achieve high repair efficiency, outstanding synergistic effect, and the effects of promoting absorption and passivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

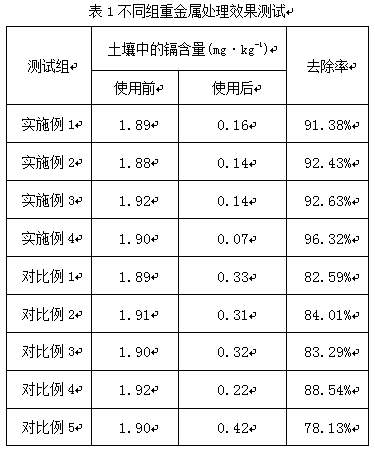

Examples

Embodiment 1

[0016] Embodiment 1: heavy metal polluted soil remediation agent is made through the following steps:

[0017] a. After fermenting 162 kg of pig manure, dry it, crush and grind it after drying, and control the particle size at 2-5mm;

[0018] B, 1.6 kilograms of sodium cocoyl sarcosinate and 8 kilograms of sodium cocoyl isethionate are all mixed with water and are the aqueous solution that concentration is 10.0g / L;

[0019] c. Calcining 56 kg of medical stone at 200-300°C for 2-4 hours, cooling and grinding into powder, then adding the aqueous solution of sodium cocoyl sarcosinate and cocoyl isethionate prepared in step b Sodium aqueous solution, mixed uniformly to obtain mixture A;

[0020] d, after drying the mixture A in step c, carry out crushing and grinding treatment, control the particle size to be 100 mesh, then add it to the pig manure in step a and mix uniformly to obtain mixture B;

[0021] E, 9.4 kilograms of composite bacterial agents are added to the mixture B ...

Embodiment 2

[0022] Embodiment 2: Heavy metal polluted soil remediation agent is made through the following steps:

[0023] a. After fermenting 188 kg of pig manure, dry it, crush and grind it after drying, and control the particle size at 2-5mm;

[0024] B, 7.4 kilograms of sodium cocoyl sarcosinate and 6.8 kilograms of sodium cocoyl isethionate are all mixed with water and are the aqueous solution that concentration is 10.0g / L;

[0025] c. Calcining 64 kg of medical stone at 200-300°C for 2-4 hours, cooling and grinding into powder, then adding the aqueous solution of sodium cocoyl sarcosinate and cocoyl isethionate prepared in step b Sodium aqueous solution, mixed uniformly to obtain mixture A;

[0026] d, after drying the mixture A in step c, carry out crushing and grinding treatment, control the particle size to be 100 mesh, then add it to the pig manure in step a and mix uniformly to obtain mixture B;

[0027] e. Add 11.0 kilograms of composite bacterial agent to the mixture B of s...

Embodiment 3

[0028] Embodiment 3: Heavy metal polluted soil remediation agent is made through the following steps:

[0029] a. After fermenting 200 kg of pig manure, dry it, crush and grind it after drying, and control the particle size at 2-5mm;

[0030] B, 8.8 kilograms of sodium cocoyl sarcosinate and 2.4 kilograms of sodium cocoyl isethionate are all mixed with water and are the aqueous solution that concentration is 10.0g / L;

[0031] c. Calcining 86 kg of medical stone at 200-300°C for 2-4 hours, cooling and grinding into powder, then adding the aqueous solution of sodium cocoyl sarcosinate and cocoyl isethionate prepared in step b Sodium aqueous solution, mixed uniformly to obtain mixture A;

[0032] d, after drying the mixture A in step c, carry out crushing and grinding treatment, control the particle size to be 100 mesh, then add it to the pig manure in step a and mix uniformly to obtain mixture B;

[0033] E, 12.2 kilograms of composite bacterial agents are added to the mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com