Brewing method and distillation equipment for white spirits

A technology of distillation equipment and liquor, which is applied in the field of liquor brewing methods and distillation equipment, can solve the problems of slow esterification reaction, low rate of starchy liquor, long time required, etc., and achieve the goal of reducing energy consumption and stabilizing the distillation environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

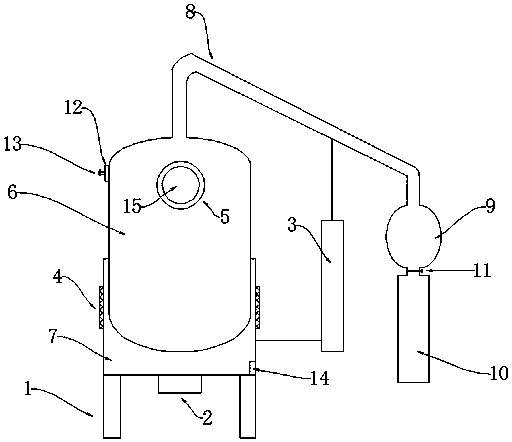

Image

Examples

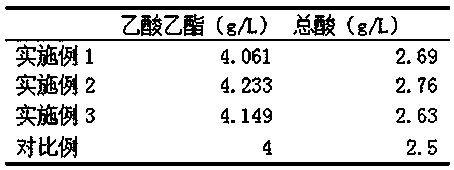

Embodiment 1

[0030] A brewing method of liquor, comprising:

[0031] (1) Remove impurities and soak grains: crush sorghum and glutinous rice to remove impurities, the weight ratio is 6:5, pass through a 20-mesh sieve, put them in a retort, soak them in hot water at 100°C, and let them cool naturally after stirring. 8cm higher than grain, soaking time 24h;

[0032] (2) Steamed grains: After soaking the grains, the water is released, and the raw materials are steamed until they are cooked but not rotten, and the time is 120 minutes;

[0033] (3) Spread cold koji: cool the steamed grains, cool down to 25°C, add Daqu three times, add 20% of the total amount of Daqu for the first time, stir and control the temperature at 40°C, add Daqu for the second time 40% of the total amount, stir and control the temperature at 35°C, add 40% of the total amount of Daqu for the third time, stir and control the temperature at 28°C, and saccharify for 72 hours until the surface of the grain is pulverized to o...

Embodiment 2

[0038] A brewing method of liquor, comprising:

[0039] (1) Remove impurities and soak grains: crush sorghum and glutinous rice to remove impurities, the weight ratio is 6:4, pass through a 20-mesh sieve, put them in a retort, soak them in hot water at 90°C, and let them cool naturally after stirring. 10cm higher than grain, soaking time 24h;

[0040](2) Steamed grains: After soaking the grains, the water is discharged, and the raw materials are steamed until they are cooked but not rotten, and the time is 100 minutes;

[0041] (3) Spread cold koji: cool the steamed grains, cool down to 25°C, add Daqu three times, add 20% of the total amount of Daqu for the first time, stir and control the temperature at 40°C, add Daqu for the second time 40% of the total amount, stir and control the temperature at 35°C, add 40% of the total amount of Daqu for the third time, stir and control the temperature at 28°C, and saccharify for 72 hours until the surface of the grain is pulverized to ...

Embodiment 3

[0046] A brewing method of liquor, comprising:

[0047] (1) Remove impurities and soak grain: crush sorghum and glutinous rice to remove impurities, the weight ratio is 6:4, pass through a 20-mesh sieve, put them in a retort, soak them in hot water at 95°C, and let them cool naturally after stirring. 12cm higher than grain, soaking time 24h;

[0048] (2) Steamed grain: After soaking the grain, the water is released, and the raw material is steamed until it is cooked but not rotten, and the time is 60 minutes;

[0049] (3) Spread cold koji: cool the steamed grains, cool down to 25°C, add Daqu three times, add 20% of the total amount of Daqu for the first time, stir and control the temperature at 40°C, add Daqu for the second time 40% of the total amount, stir and control the temperature at 35°C, add 40% of the total amount of Daqu for the third time, stir and control the temperature at 28°C, and saccharify for 72 hours until the surface of the grain is pulverized to obtain win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com