High-temperature oxidation and corrosion resistant coating alloy and coating

A high-temperature anti-oxidation and anti-corrosion coating technology, which is applied in the fields of high-temperature turbine working blades, high-temperature anti-oxidation and anti-corrosion coating alloys and coatings, can solve problems such as high-temperature anti-oxidation and anti-corrosion coating systems that have not yet been developed, and achieve Better anti-oxidation and corrosion effect, strong anti-oxidation and corrosion resistance at high temperature, and simple alloy composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

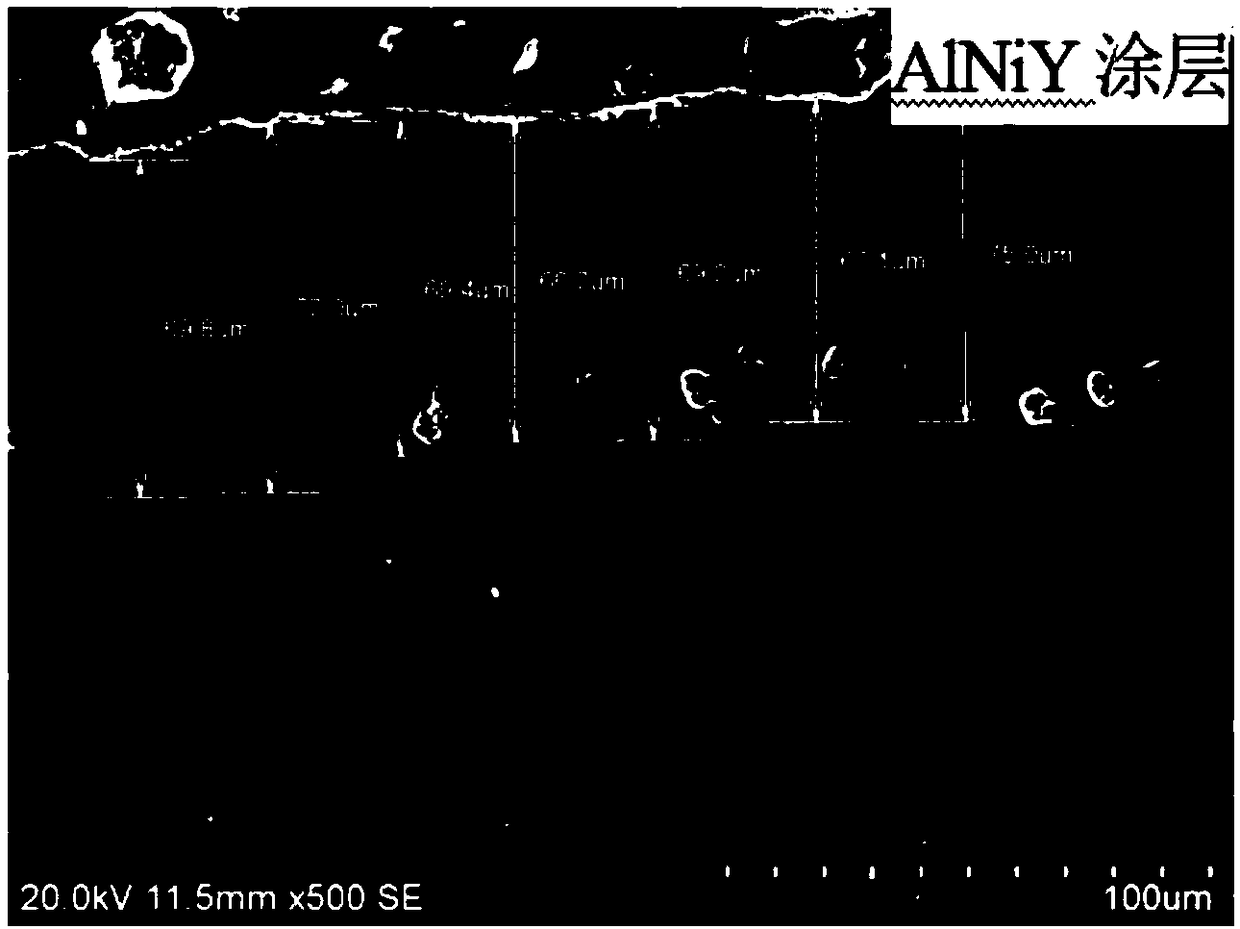

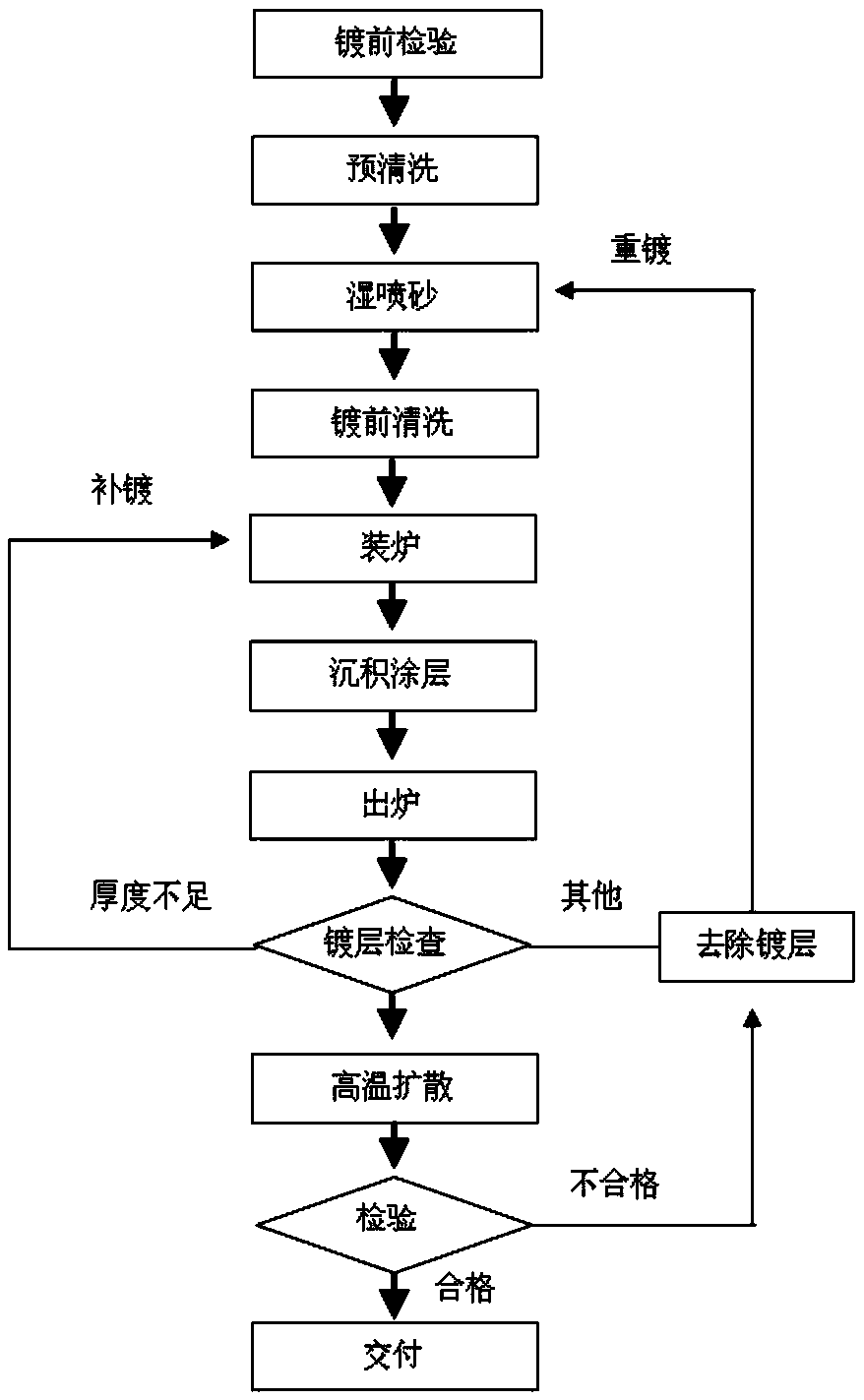

[0046] In this embodiment, the alloy composition of the coating after vacuum melting is shown in Table 1; the mold shell material of the cathode target casting is alumina, the mold shell roasting temperature is 900 ° C, the roasting time is not less than 4 hours, the refining temperature is 1000 ° C, pouring The temperature is 950°C. Castings are machined into qualified targets. Coating preparation process such as figure 2 shown. A test piece coated with AlNiY coating and heat-treated, bent at 90° for inspection, such as image 3 As shown, the coating has cracked, but there is no phenomenon such as peeling and peeling. The above inspection results meet the inspection requirements for the coating appearance quality and coating thickness, as well as the inspection requirements for the adhesion of the coating.

[0047] Table 1 Embodiment 1 coating alloy chemical composition (wt%)

[0048] Ni

Embodiment 2

[0050] In this embodiment, the coating alloy composition after vacuum smelting is shown in Table 2; the mold shell material of the cathode target casting is alumina, the mold shell roasting temperature is 800°C, the roasting time is not less than 4 hours, and the alloy refining temperature is 1000°C °C, the pouring temperature is 900 °C. The casting is machined into a qualified cathode target. Coating preparation process such as figure 2 shown. The XRD analysis results of AlNiY coating oxidation at 900 °C and 1000 °C are as follows Figure 4 shown. AlNiY coating was oxidized at 900℃ for 100h. Compared with the coating before oxidation, the structure of the coating did not change much. The XRD analysis results show that the coating is divided into two layers, the outer layer is a single-phase β-NiAl, and the diffusion layer is composed of a β-NiAl phase and a small granular white carbide precipitate, but the granular white carbide aggregates and grows . With the prolonga...

Embodiment 3

[0054] In this embodiment, the alloy composition of the coating after vacuum melting is shown in Table 3; the mold shell material of the cathode target casting is alumina, the mold shell roasting temperature is 880°C, the roasting time is not less than 4 hours, and the alloy refining temperature is 950°C , The pouring temperature is 900°C. The casting is machined into a qualified cathode target.

[0055] AlNiY coating preparation process such as figure 2 shown. Figure 5 It is the surface oxide morphology of the AlNiY coating after oxidation at 1000 °C for different times. After oxidizing for 10h, uniform needle-like θ-Al was formed on the surface 2 o 3 ( Figure 5 a); Oxidation 100h, θ-Al 2 o 3 Grow into a typical needle flake ( Figure 5 b) After oxidation for 1100h, most of the needle-like oxides on the surface of DD32 aluminized coating have been transformed into equiaxed α-Al 2 o 3 , indicating that the θ→α-Al 2 o 3 Phase transition, but needle flake θ-Al can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com