Modification treatment method for enhancing antibacterial property of polyester fiber

A polyester fiber and treatment method technology, which is applied in the field of modification treatment to enhance the antibacterial performance of polyester fiber, can solve the problems of non-antibacterial performance, etc., and achieve the effects of improving reaction ability and surface activity, good antibacterial stability, and good mechanical quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

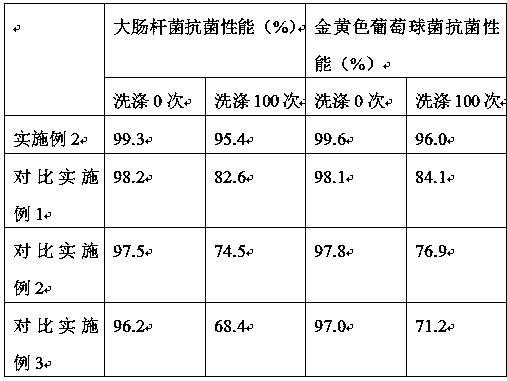

Examples

Embodiment 1

[0027] A modification treatment method for enhancing the antibacterial properties of polyester fibers, comprising the steps of:

[0028] (1) Polyester fiber pretreatment:

[0029] First immerse the polyester fiber in the sodium hydroxide solution, then heat to keep the temperature of the sodium hydroxide solution at 48°C, keep stirring for 2 hours, then take out the polyester fiber, and finally rinse it with deionized water and dry it for later use;

[0030] (2) Preparation of composite soaking solution:

[0031] a. Take the following materials in corresponding parts by weight: 1 part of silver nitrate, 5 parts of zinc nitrate, 90 parts of deionized water, and then put them into the stirring tank together, and after magnetic stirring for 30 minutes, add the other ingredients in the stirring tank Phytic acid with a total mass of 6% was treated with magnetic stirring for 20 minutes, then ammonia water was added to the stirring tank to adjust the overall pH value to 7.5, and the...

Embodiment 2

[0046] A modification treatment method for enhancing the antibacterial properties of polyester fibers, comprising the steps of:

[0047] (1) Polyester fiber pretreatment:

[0048] First immerse the polyester fiber into the sodium hydroxide solution, then heat to keep the temperature of the sodium hydroxide solution at 50°C, keep stirring for 2.1 hours, then take out the polyester fiber, and finally rinse it with deionized water and dry it for later use;

[0049] (2) Preparation of composite soaking solution:

[0050] a. Take the following materials in corresponding parts by weight: 2 parts of silver nitrate, 7 parts of zinc nitrate, 95 parts of deionized water, and then put them into the stirring tank together, and after magnetic stirring for 33 minutes, add the other ingredients in the stirring tank Phytic acid with a total mass of 8% was treated with magnetic stirring for 23 minutes, then ammonia water was added to the stirring tank to adjust the overall pH value to 7.8, an...

Embodiment 3

[0065] A modification treatment method for enhancing the antibacterial properties of polyester fibers, comprising the steps of:

[0066] (1) Polyester fiber pretreatment:

[0067] First immerse the polyester fiber into the sodium hydroxide solution, then heat to keep the temperature of the sodium hydroxide solution at 53°C, keep stirring for 2.2 hours, then take out the polyester fiber, and finally rinse it with deionized water and dry it for later use;

[0068] (2) Preparation of composite soaking solution:

[0069] a. Take the following materials in corresponding parts by weight: 3 parts of silver nitrate, 8 parts of zinc nitrate, 100 parts of deionized water, and then put them into the stirring tank together, and after magnetic stirring for 35 minutes, add the other ingredients in the stirring tank Phytic acid with a total mass of 9% was treated with magnetic stirring for 25 minutes, then ammonia water was added to the stirring tank to adjust the overall pH value to 8.0, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com