Cold-formed thin-walled steel tic-tac-toe floor slab structure and construction method thereof

A technology of cold-formed thin-walled steel and construction methods, applied in floors, building components, building structures, etc., can solve the problems of low stability performance, sound insulation of floors, fire prevention, waterproof and load-bearing performance, high maintenance frequency, etc., and achieve stability Strong performance, reduced on-site construction workload, and low maintenance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

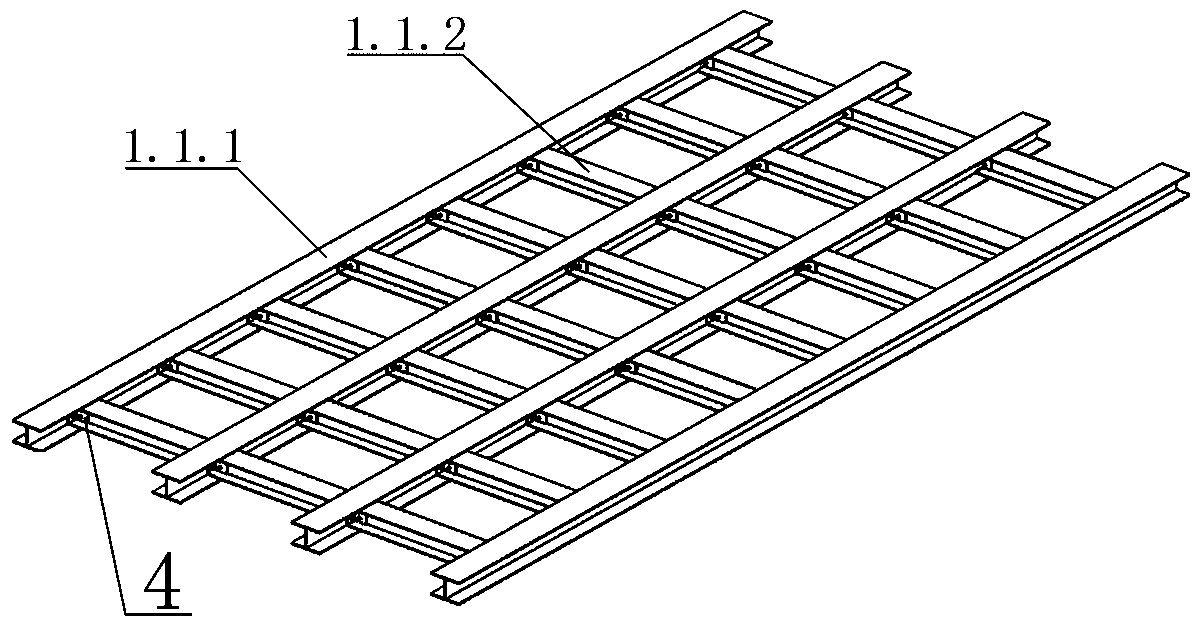

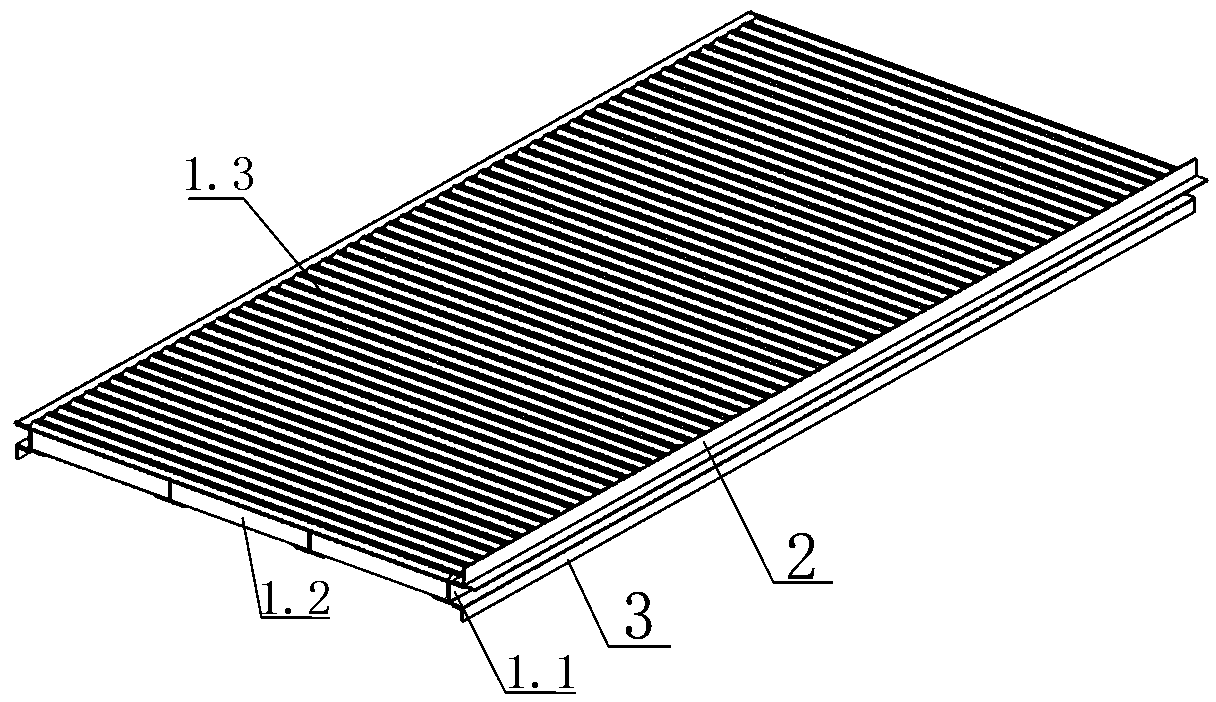

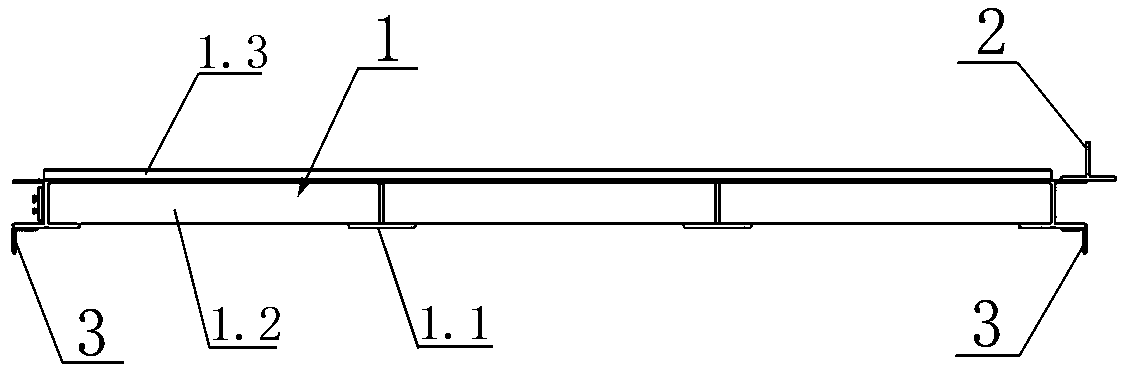

[0035] Such as Figure 1-8 As shown, this cold-formed thin-walled steel well-shaped floor structure includes a group of floor modules 1 spliced in sequence and a lightweight concrete layer 6 poured on a group of floor modules 1; the floor module 1 includes light steel Frame 1.1, thermal insulation board 1.2 and profiled steel plate 1.3; the light steel frame 1.1 is a rectangular frame structure formed by connecting one group of longitudinal steel rods 1.1.1 and at least two groups of transverse steel rods 1.1.2; the There is one group of insulation boards 1.2, which are correspondingly filled in the sash of the light steel frame 1.1; the profiled steel plate 1.3 is laid on the top of the light steel frame 1.1 and covered on a group of insulation boards 1.2; on the top of each floor module 1 On one side, a baffle 2 is provided along the longitudinal edge of the light steel frame 1.1, and the baffle 2 on the adjacent floor modules 1 after splicing constitutes a side formwork f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com