Oilless air compressor

A technology for oil-free air compressors and motor shafts, which is applied in mechanical equipment, machines/engines, liquid variable capacity machines, etc. It can solve the problems of eccentric shaft bearing wear, reduced service life, and unstable fan blades, etc., to achieve Stable operation and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

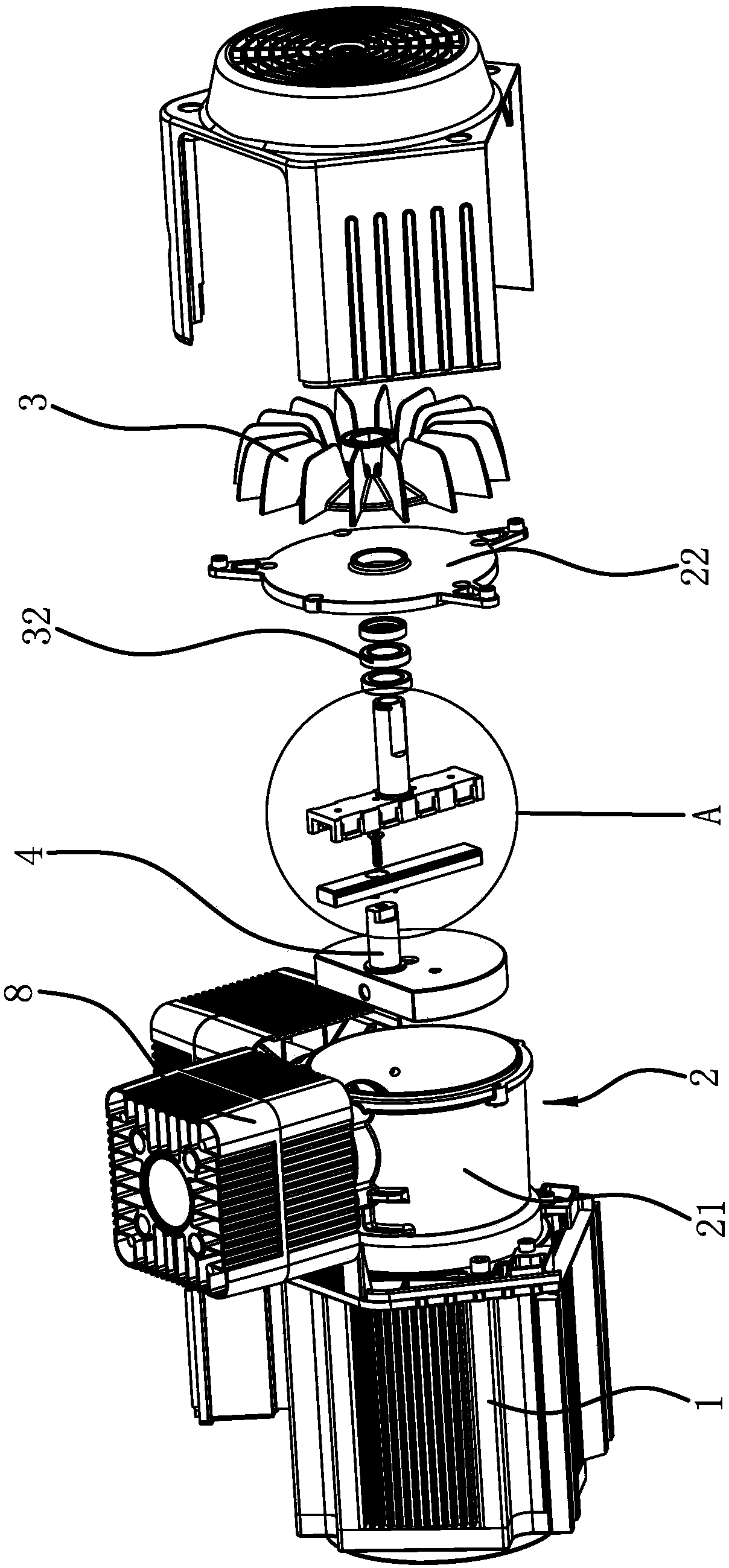

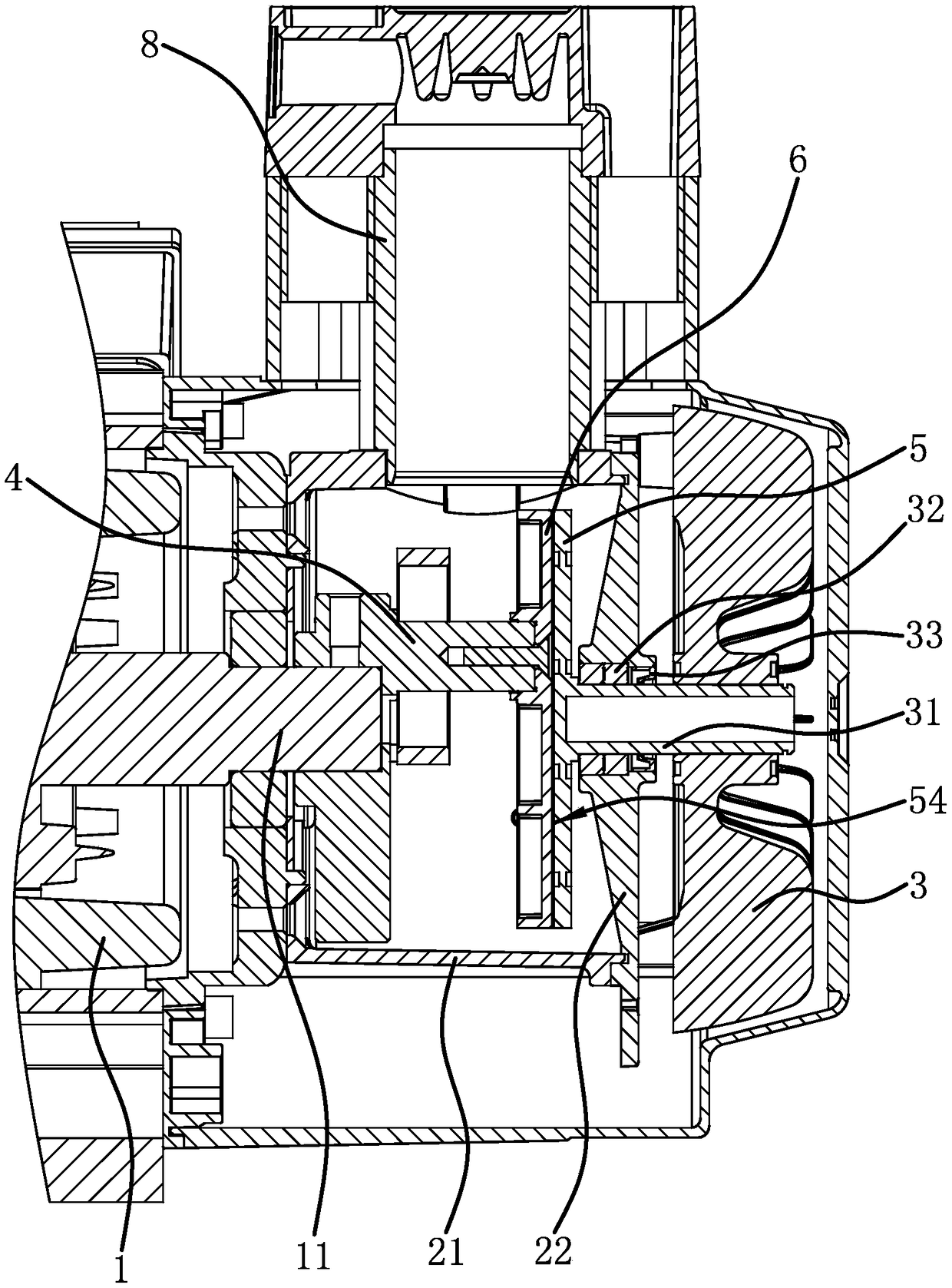

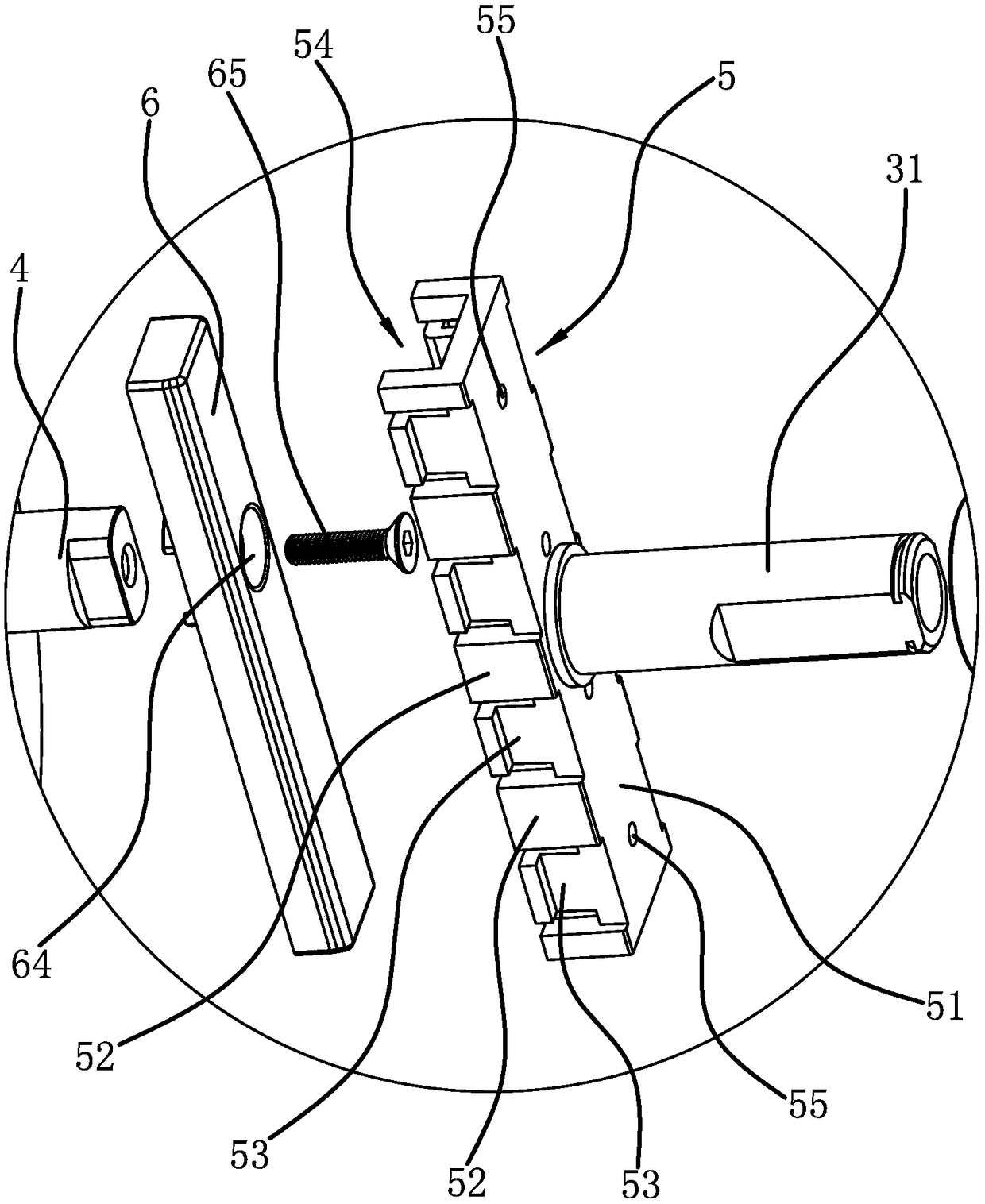

[0035] Such as figure 1 As shown, an oil-free air compressor includes a motor 1, a crankcase 2 and fan blades 3, the crankcase 2 includes a box body 21 and a box cover 22, the motor 1 is fixedly connected to one end of the box body 21, and the box cover 22 is fixed on The other end of casing 21, fan blade 3 is fixed with fan blade shaft 31, and fan blade shaft 31 passes case cover 22 and stretches in the casing 21, and fan blade shaft 31 is connected on the case cover 22 by bearing 32 rotation, in A seal 33 is also installed between the vane shaft 31 and the case cover 22, and two cylinders 8 are fixed on the top of the outer wall of the casing 21, and the two cylinders 8 are arranged in a V shape. figure 2 As shown, the motor shaft 11 of the motor 1 extends into the box body 21, and a crankshaft 4 is fixed at the end of the motor shaft 11. The crankshaft 4 is parallel to the motor shaft 11 and arranged eccentrically, and the motor shaft 11 and the blade shaft 31 Relatively ...

Embodiment 2

[0038] The structure of the oil-free air compressor is basically the same as that of Embodiment 1, the difference is that Figure 8 As shown, there is a strip-shaped notch 54 arranged along the length direction on the connecting plate 5, and the notch 54 faces the crankshaft 4, and the end of the crankshaft 4 is vertically inserted into the notch 54. This structure cancels the crankshaft 4. The connection bar 6 directly inserts the end of the crankshaft 4 into the notch 54 of the connection plate 5, which can also achieve the purpose of driving the connection plate 5 to rotate and simplify the overall structure.

Embodiment 3

[0040] The structure of the oil-free air compressor is basically the same as that of Embodiment 1, the difference is that Figure 9 As shown, the connecting piece includes a rigid connecting bar 6 fixedly connected to the end of the crankshaft 4, and the connecting bar 6 is arranged along the direction of the vertical line between the motor shaft 11 and the crankshaft 4, and the end surface of the blade shaft 31 is radially provided with sliding Groove 34, connecting bar 6 is slidably connected in the slide groove 34.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com