A Design Method of Textured Interference-Joint Face Group

A design method and connection surface technology, applied in the direction of connection components, shrinkage connection, mechanical equipment, etc., can solve the problem of large stress concentration on the mating surface, and achieve the effect of improving contact stiffness, strength, and overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

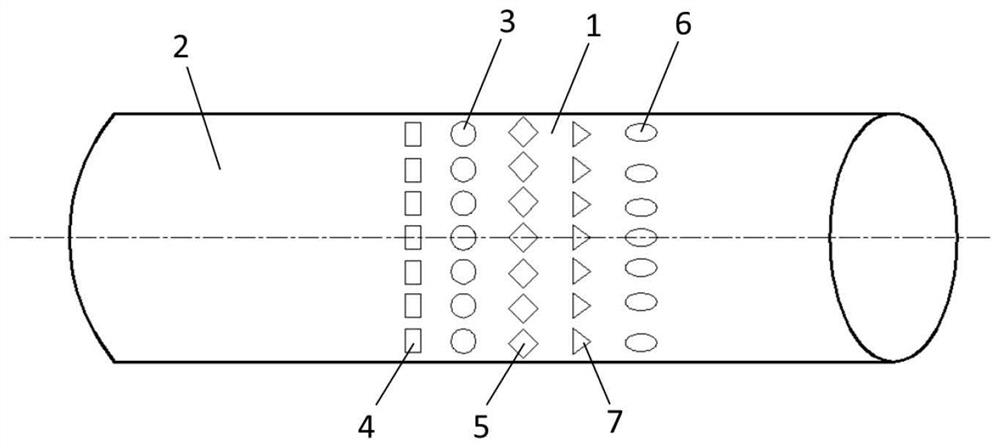

[0032] The connection surface group composed of the outer circle of the pin shaft and the inner circle of the pin hole is the most common interference connection of mechanical equipment. The following is combined with the attached Figure 4 The present invention will be further described by taking a square textured pin shaft as an example.

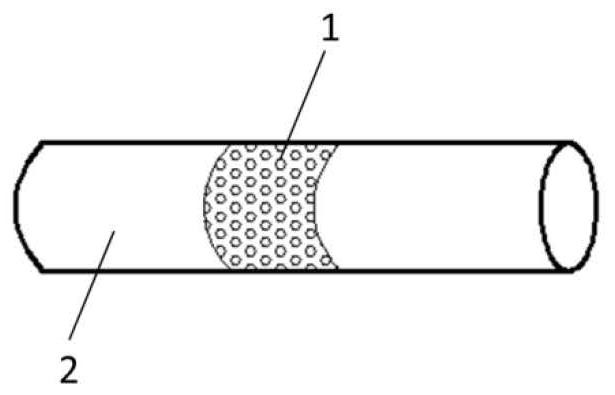

[0033] In the present invention, a textured area 1 and an untextured area 2 are designed on the interference fit connection surface formed by the pin shaft and the pin hole.

[0034] The texture zone is only designed on the outer circular mating surface of the pin shaft (see Figure 4 )superior.

[0035] The textured area 1 is provided with square pits 3 .

[0036] The square pits 3 are arranged in rows and columns parallel to the axial direction of the pin axis (ie 0°).

[0037] The geometric parameters of the square pit 3 are: the side length is 10-500um, and the depth is 2-50um.

[0038] The distance between adjacent square pits in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com