Planetary gear train of automatic transmission for vehicles

A planetary gear train, automatic transmission technology, applied in the direction of vehicle transmission, vehicle components, gear transmission, etc., can solve the problem of the linearity of the gear ratio of the eight-speed automatic transmission, and reduce the resistance loss and increase the torque. Effects of transmission efficiency and durability, improved power delivery efficiency and fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following description is merely exemplary in nature and is not intended to limit the invention, application, or uses. It should be understood that

[0041] In the following description, the names of the components are divided into first, second, etc. in order to divide the names, because the names of the components

[0042] Furthermore, as used herein, a description of "directly" connected or interconnected elements includes fixedly connected elements, i.e.

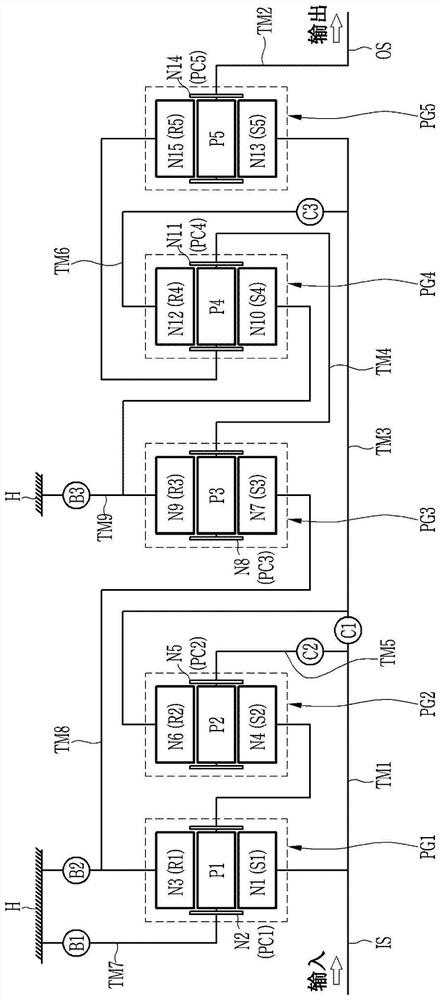

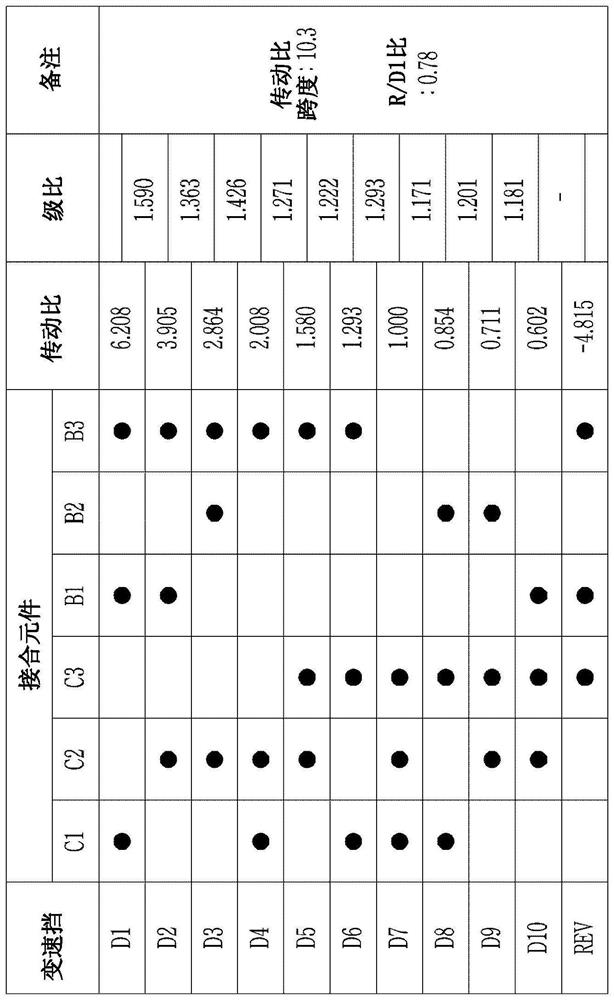

[0044] Referring to FIG. 1, the planetary gear train includes: first, second, third, fourth and fifth rows arranged on the same axis

[0046] According to an exemplary embodiment of the present invention, the first, second and third, fourth and fifth rows from the engine side

[0055] The nine axes TM1 to TM9 are arranged as follows:

[0056] Each of the nine shafts TM1 to TM9 may be a link between the input and output shafts and the planetary gear sets PG1, PG2,

[0061] The fifth shaft TM5 is connected to the fif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com