Spiral plate heat exchanger with protection function for sludge and working method thereof

A heat exchanger and spiral plate technology, applied in the field of spiral plate heat exchangers for sludge, can solve the problems of increasing maintenance and equipment investment costs, affecting the work of the heat exchange system, and easily blocking the sludge, and achieving good protection effects. , the effect of alleviating friction and reducing the amplitude of oscillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

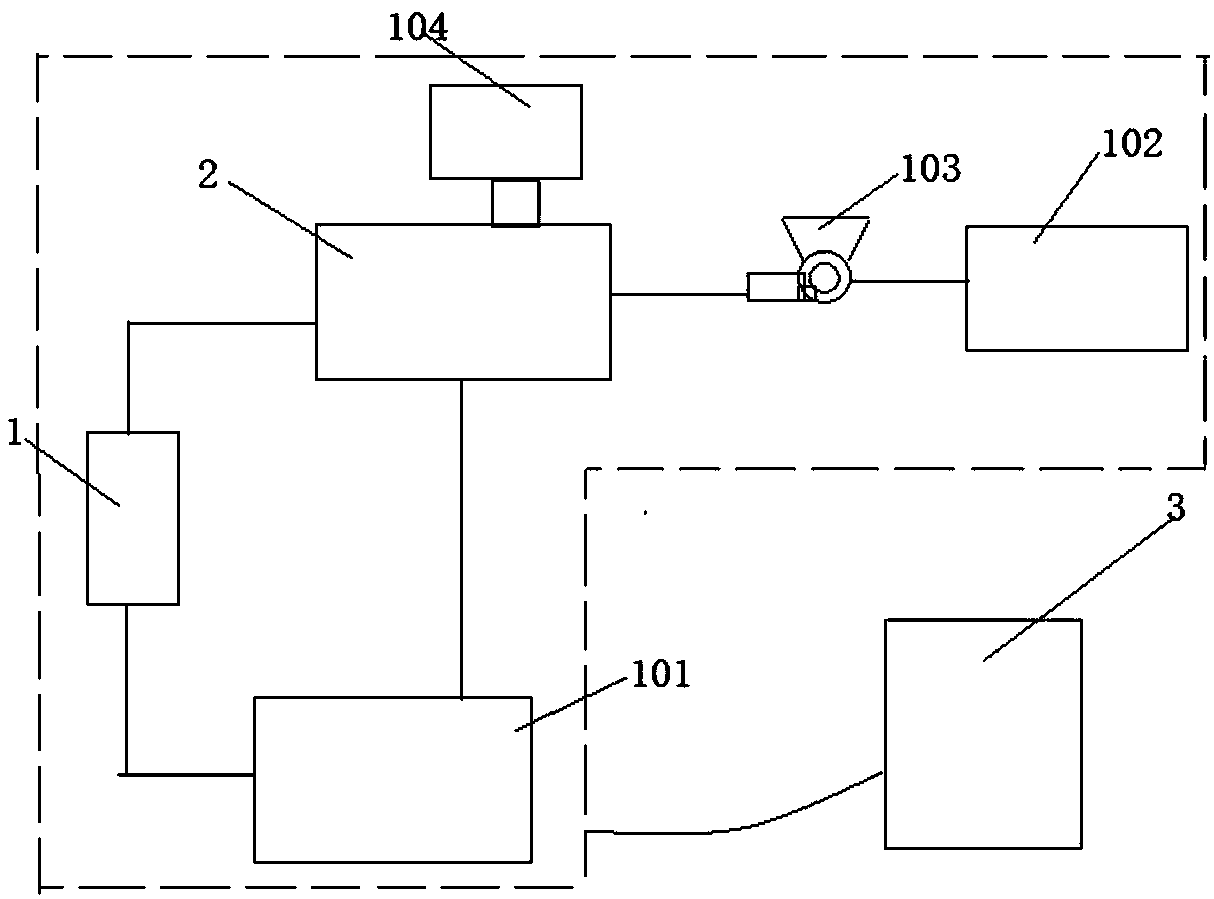

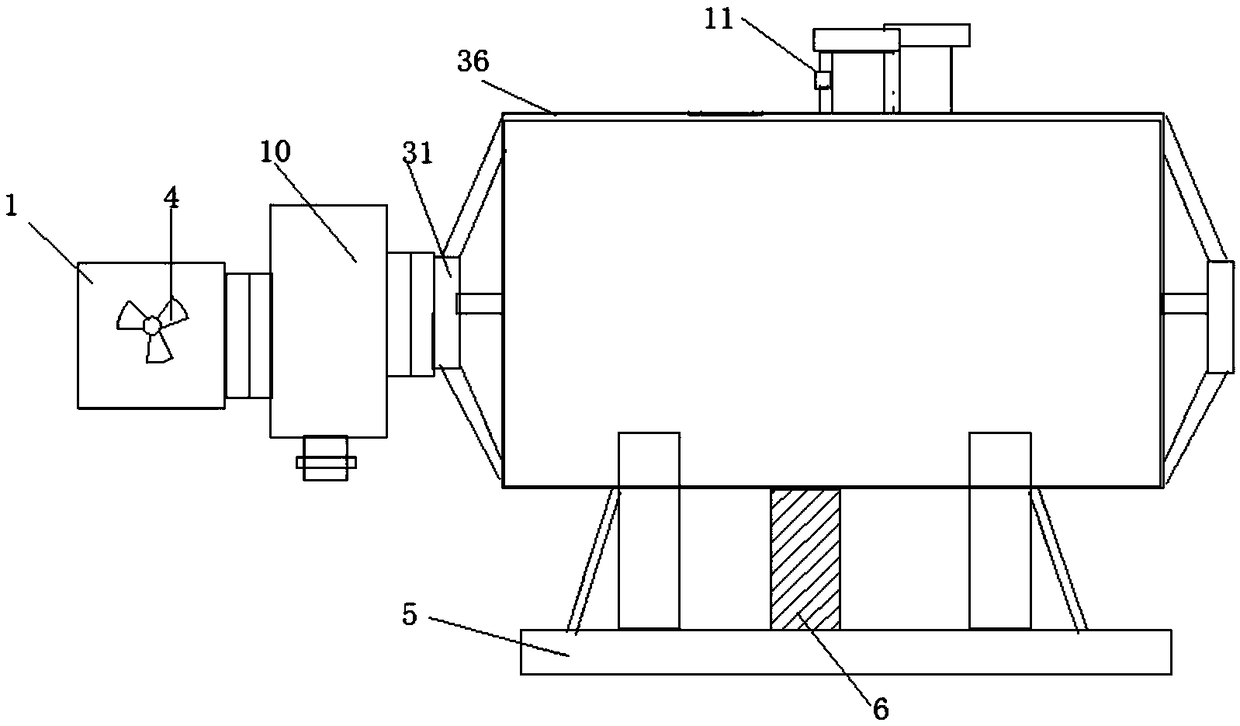

[0042] A spiral plate heat exchanger with protective function described in this embodiment includes: a feeding device 1, a heat exchanger 2 and a control device 3, and the feeding device 1 is provided with a stirring device 4 , the input end of the feeding device 2 is connected to the sludge heat processor 101 through a pipeline, the outlet end of the feeding device 2 is connected to the heat exchanger 2, and a fixing frame 5 is provided under the heat exchanger 2 , the fixed frame 5 is provided with a shock absorbing mechanism 6, the output end of the heat exchanger 2 is connected to the heat recovery mechanism 102 through a pipeline, and a circulating fan is arranged between the heat exchanger 2 and the heat recovery mechanism 102 103;

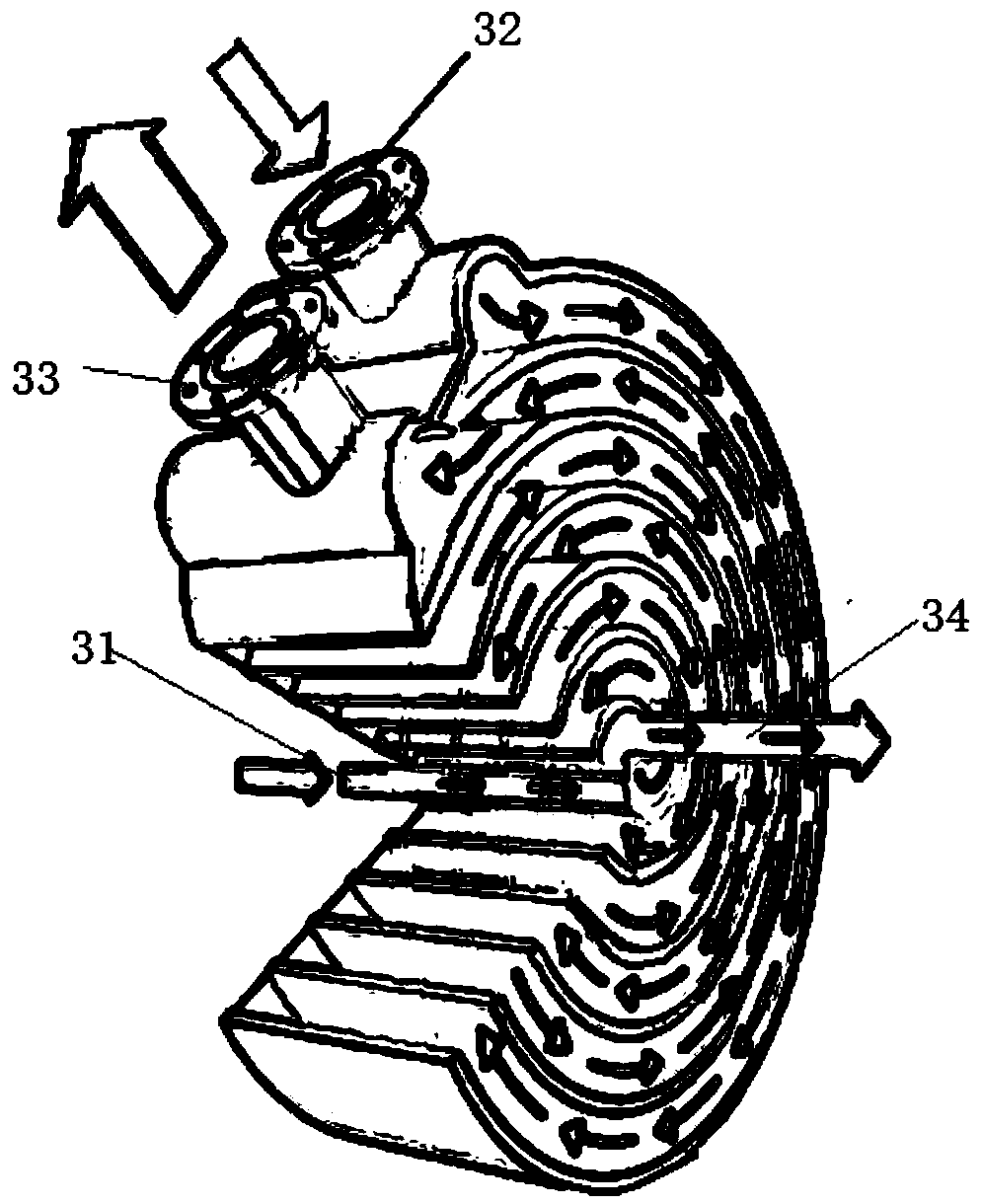

[0043] The heat exchanger 2 adopts a spiral plate exchange structure, and is made of two groups of metal plates rolled into a spiral plate shape to form two circulation paths, in which there are two circulation paths, namely the first circul...

Embodiment 2

[0046] A spiral plate heat exchanger with protective function described in this embodiment includes: a feeding device 1, a heat exchanger 2 and a control device 3, and the feeding device 1 is provided with a stirring device 4 , the input end of the feeding device 2 is connected to the sludge heat processor 101 through a pipeline, the outlet end of the feeding device 2 is connected to the heat exchanger 2, and a fixing frame 5 is provided under the heat exchanger 2 , the fixed frame 5 is provided with a shock absorbing mechanism 6, the output end of the heat exchanger 2 is connected to the heat recovery mechanism 102 through a pipeline, and a circulating fan is arranged between the heat exchanger 2 and the heat recovery mechanism 102 103;

[0047] The heat exchanger 2 adopts a spiral plate exchange structure, and is made of two groups of metal plates rolled into a spiral plate shape to form two circulation paths, in which there are two circulation paths, namely the first circul...

Embodiment 3

[0053] A spiral plate heat exchanger with protective function described in this embodiment includes: a feeding device 1, a heat exchanger 2 and a control device 3, and the feeding device 1 is provided with a stirring device 4 , the input end of the feeding device 2 is connected to the sludge heat processor 101 through a pipeline, the outlet end of the feeding device 2 is connected to the heat exchanger 2, and a fixing frame 5 is provided under the heat exchanger 2 , the fixed frame 5 is provided with a shock absorbing mechanism 6, the output end of the heat exchanger 2 is connected to the heat recovery mechanism 102 through a pipeline, and a circulating fan is arranged between the heat exchanger 2 and the heat recovery mechanism 102 103;

[0054] The heat exchanger 2 adopts a spiral plate exchange structure, and is made of two groups of metal plates rolled into a spiral plate shape to form two circulation paths, in which there are two circulation paths, namely the first circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com