Dual-stator hybrid excitation magnetic suspension switched reluctance machine

A switched reluctance motor and hybrid excitation technology, applied in magnetic circuits, electrical components, electromechanical devices, etc., can solve the problems of low power consumption, small axial length, etc., to reduce electromagnetic power consumption, improve power density, and simplify mathematics. effect of the model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

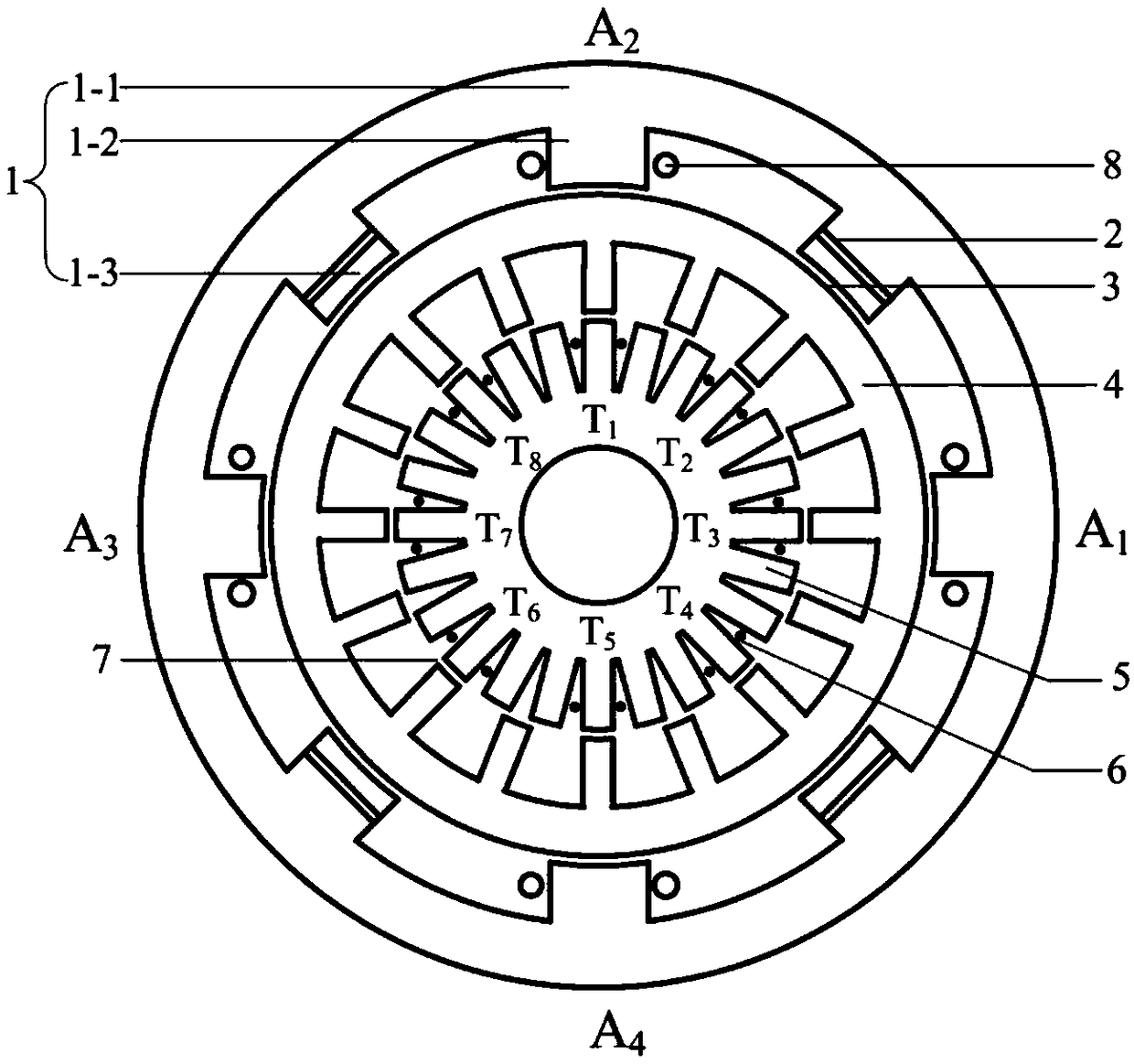

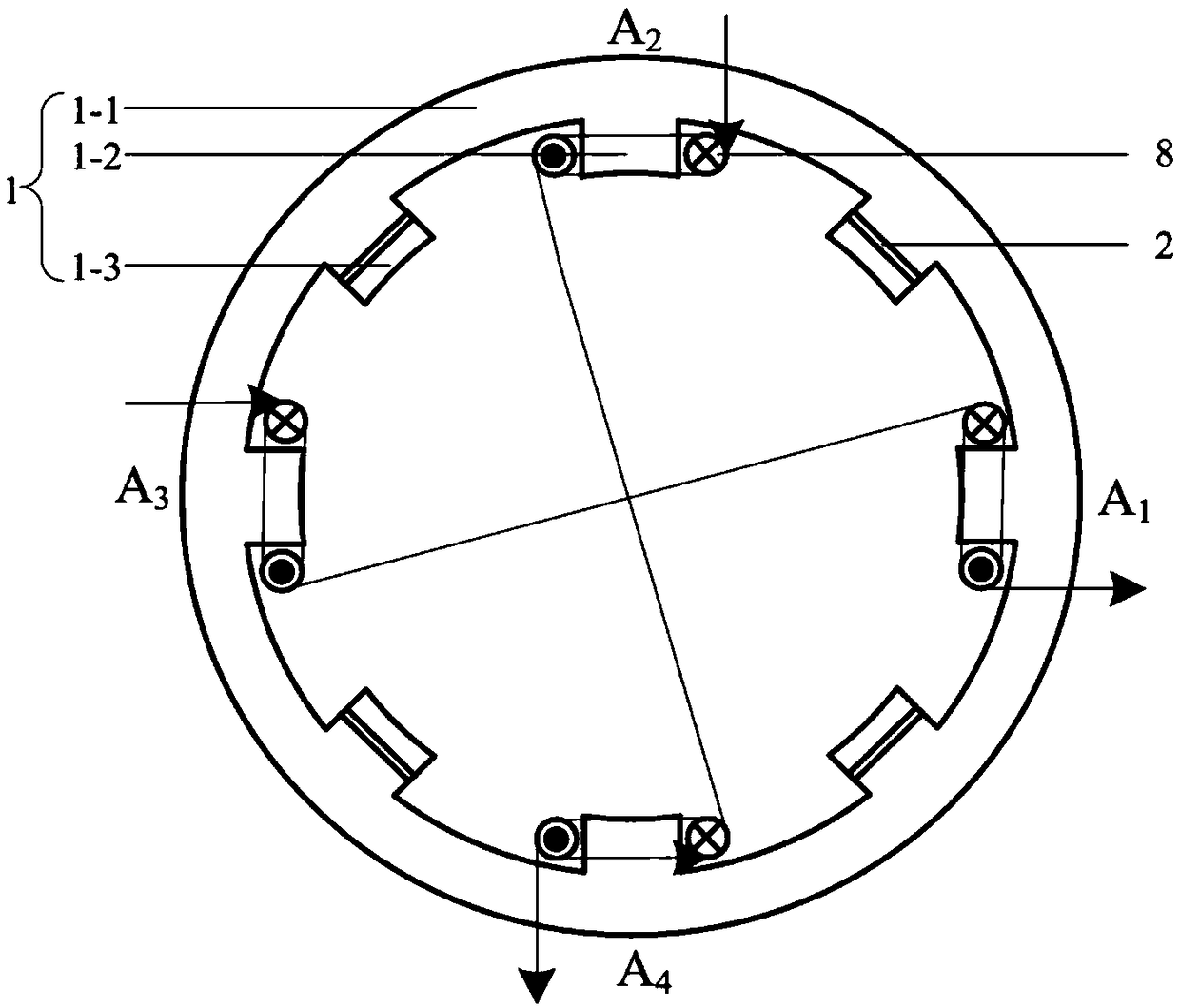

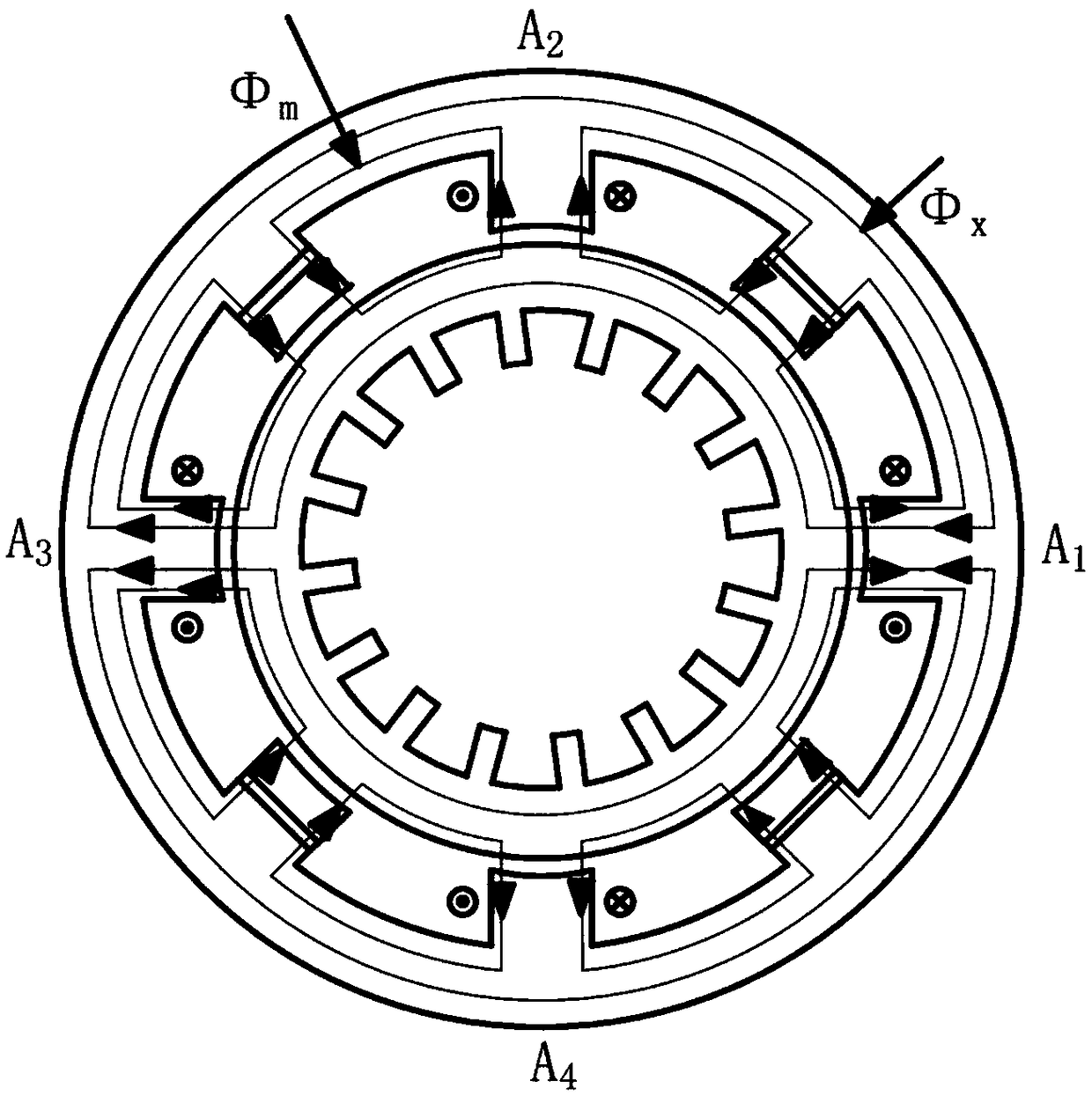

[0026] Such as figure 1 As shown, the radial structural diagram of the double-stator hybrid excitation magnetic levitation switched reluctance motor of the present invention includes a hybrid outer stator 1, a sixteen-pole rotor 4, a twenty-four-pole inner stator 5, a suspension air gap 3 and a torque air gap 7, The inner stator 5, the rotor 4 and the hybrid outer stator 1 are coaxially nested sequentially from the inside to the outside. Among them, the hybrid outer stator is composed of an outer stator yoke 1-1, four control poles 1-2, four permanent magnet poles 1-3 and a sheet permanent magnet 2, and the control poles 1-2 and permanent magnet poles 1-3 The equidistant phases are distributed on the outer stator yoke 1-1 and connected to the outer stator yoke 1-1. The four p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com