Piezoelectric automobile loudspeaker

A speaker and car technology, applied in piezoelectric/electrostrictive transducers, sensors, electrical components, etc., can solve problems such as poor low-frequency response, capacitive loads, etc., to reduce energy consumption, reduce driving voltage, The effect of reducing the frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

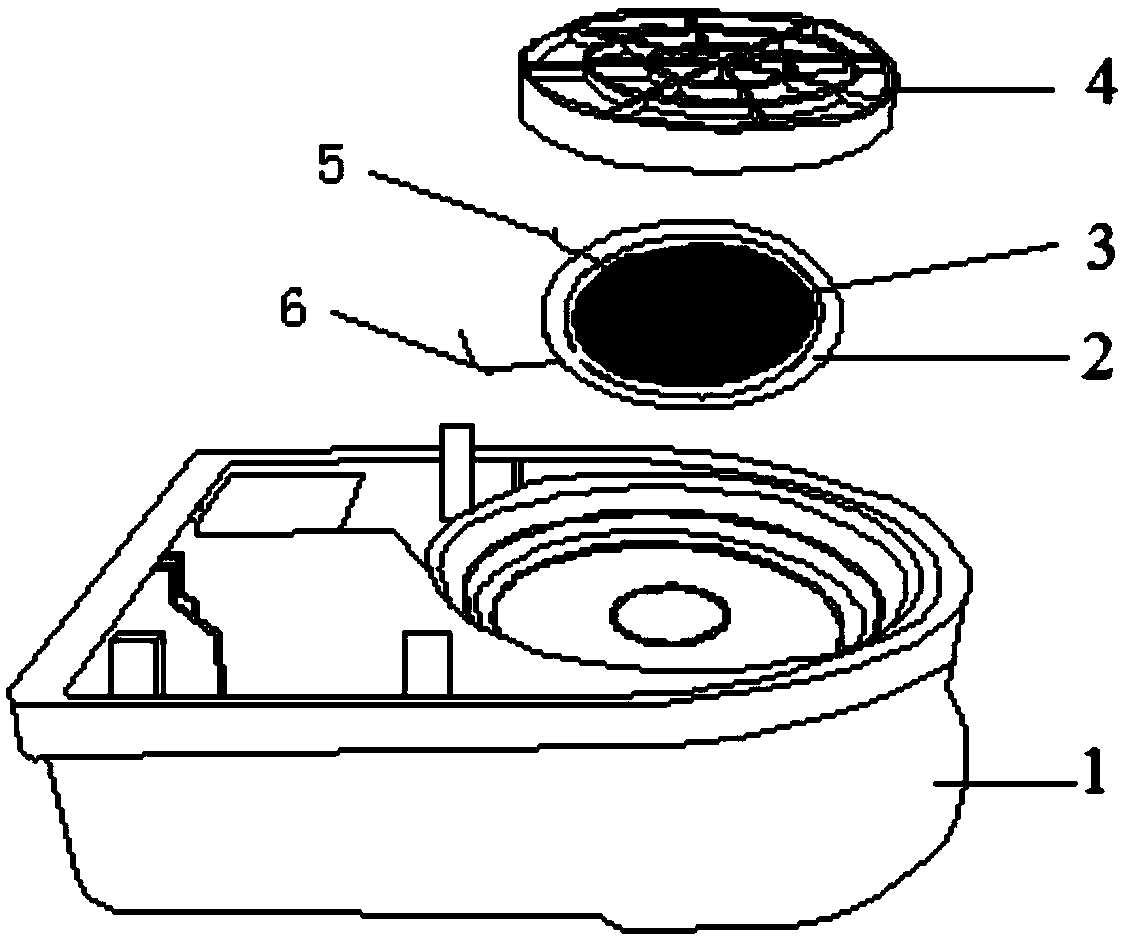

[0035] exist figure 1 Among them, the piezoelectric car speaker in this embodiment is composed of a casing 1 , a diaphragm 2 , a multilayer piezoelectric ceramic sheet 3 , a protective cover 4 , a first lead 5 , and a second lead 6 connected together.

[0036] A sounding unit is installed in the sound chamber of the shell 1, and a protective cover 4 is installed on the shell 1 above the sounding unit. The structure of the sounding unit is that the upper surface of the diaphragm 2 is pasted with a multi-layer piezoelectric ceramic sheet 3. The electric ceramic sheet 3 is connected with a first lead wire 5, and the diaphragm 2 is connected with a second lead wire 6. The diaphragm 2 is a round solid brass sheet, or a round solid stainless steel sheet, or a round solid poly Vinyl chloride tablets, such as image 3 , the multilayer piezoelectric ceramic sheet 3 is cylindrical, the cross-sectional area of the diaphragm is 2.5 times the cross-sectional area of the multilayer pie...

Embodiment 2

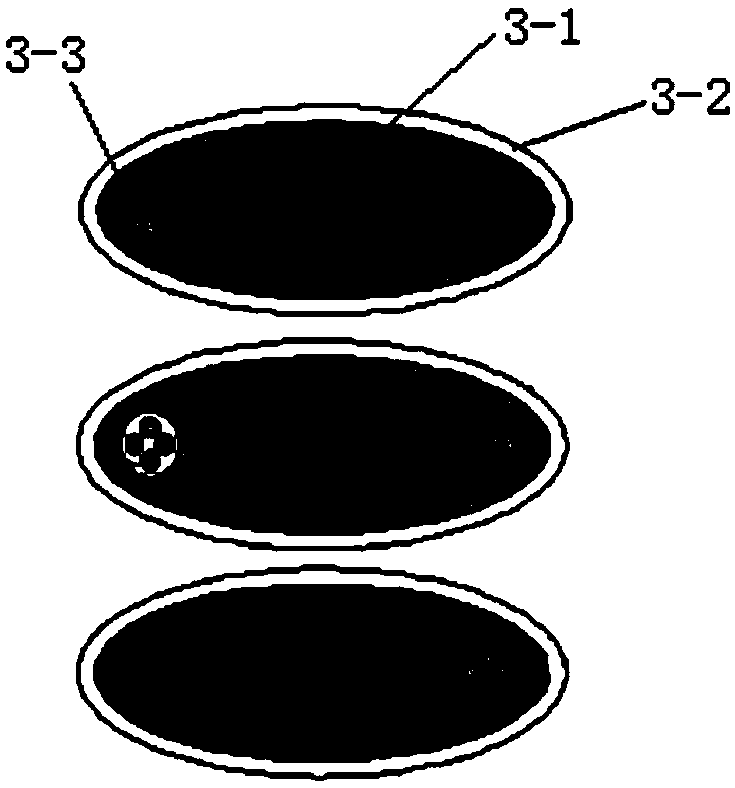

[0049] In this embodiment, a sounding unit 2 is installed in the acoustic cavity of the casing 1, and a protective cover 3 is installed on the casing 1 above the sounding unit 2. The structure of the sounding unit 2 is that the upper surface of the diaphragm 2 is pasted with a multi-layer The piezoelectric ceramic sheet 3 is connected with the first lead wire 5 on the multilayer piezoelectric ceramic sheet 3, and the second lead wire 6 is connected on the vibrating membrane 2, and the vibrating membrane 2 is a circular sheet processed with an annular hole to divide the circular sheet into outer parts. The annular sheet and the inner circular sheet, the outer annular sheet and the inner circular sheet are connected by reinforcing ribs evenly distributed along the circumferential direction, such as Figure 4 , the material of the vibrating membrane 2 is a brass sheet, or a stainless steel sheet, or a polyvinyl chloride sheet, the multilayer piezoelectric ceramic sheet 3 is cylind...

Embodiment 3

[0052] In this embodiment, a sounding unit 2 is installed in the acoustic cavity of the casing 1, and a protective cover 3 is installed on the casing 1 above the sounding unit 2. The structure of the sounding unit 2 is that the upper surface of the diaphragm 2 is pasted with a multi-layer Piezoelectric ceramic sheet 3, the multilayer piezoelectric ceramic sheet 3 is connected with the first lead wire 5, and the diaphragm 2 is connected with the second lead wire 6, and the diaphragm 2 is a square solid brass sheet, or a square solid stainless steel sheet , can also be a square solid polyvinyl chloride sheet, such as Figure 5 , the multilayer piezoelectric ceramic sheet 3 is cylindrical, and the cross-sectional area of the diaphragm is 2.5 times the cross-sectional area of the multilayer piezoelectric ceramic sheet. Other components and the connection relationship of the components are the same as in Embodiment 1.

[0053] The preparation method of the multilayer piezoelec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com