Cam type high-speed front-end machining machine

A processing machine and cam-type technology, which is applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of lathe clamps that are not easy to clamp, long processing time, and low efficiency, so as to reduce manpower and increase product output , the effect of reducing the number of machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the drawings.

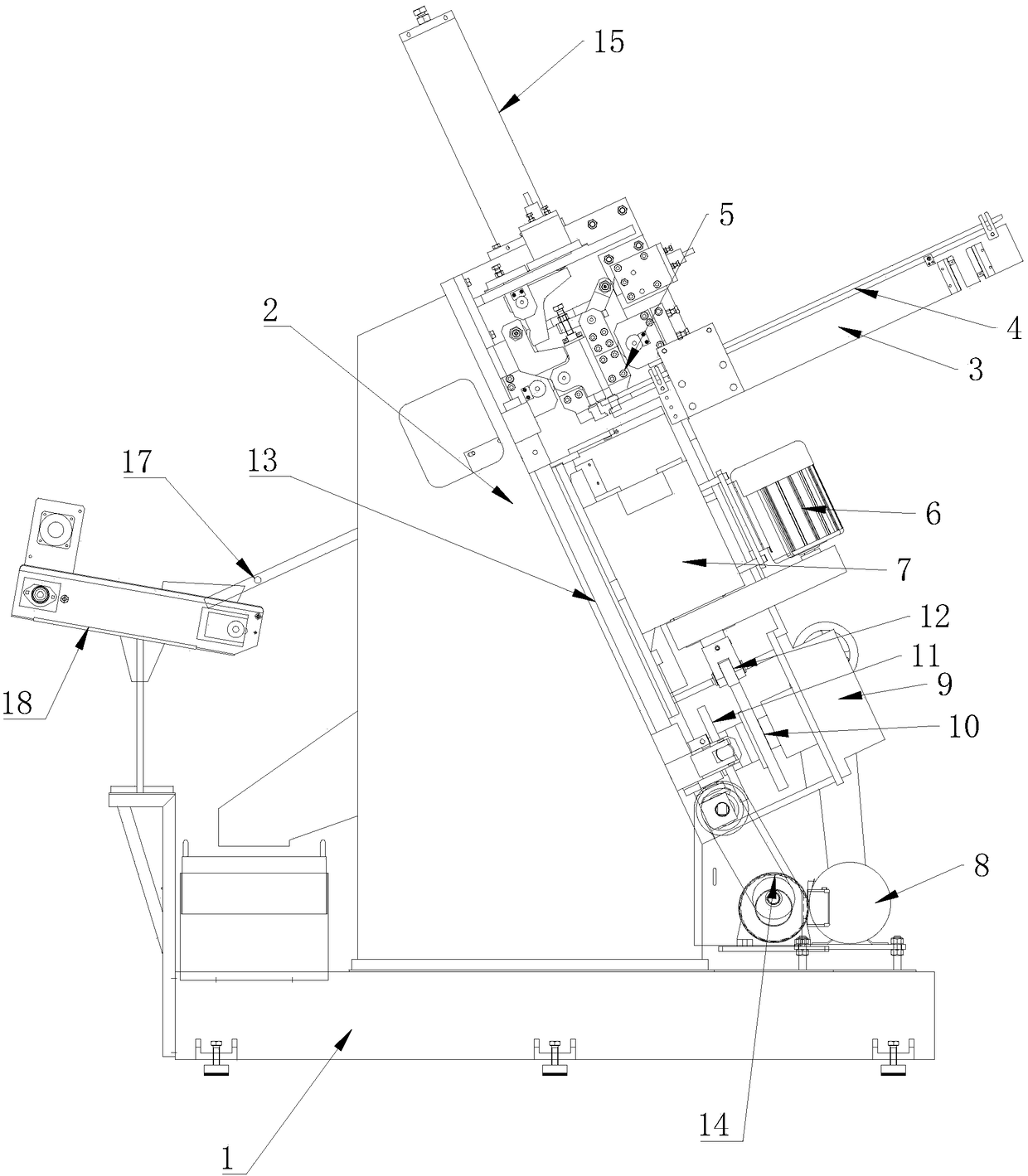

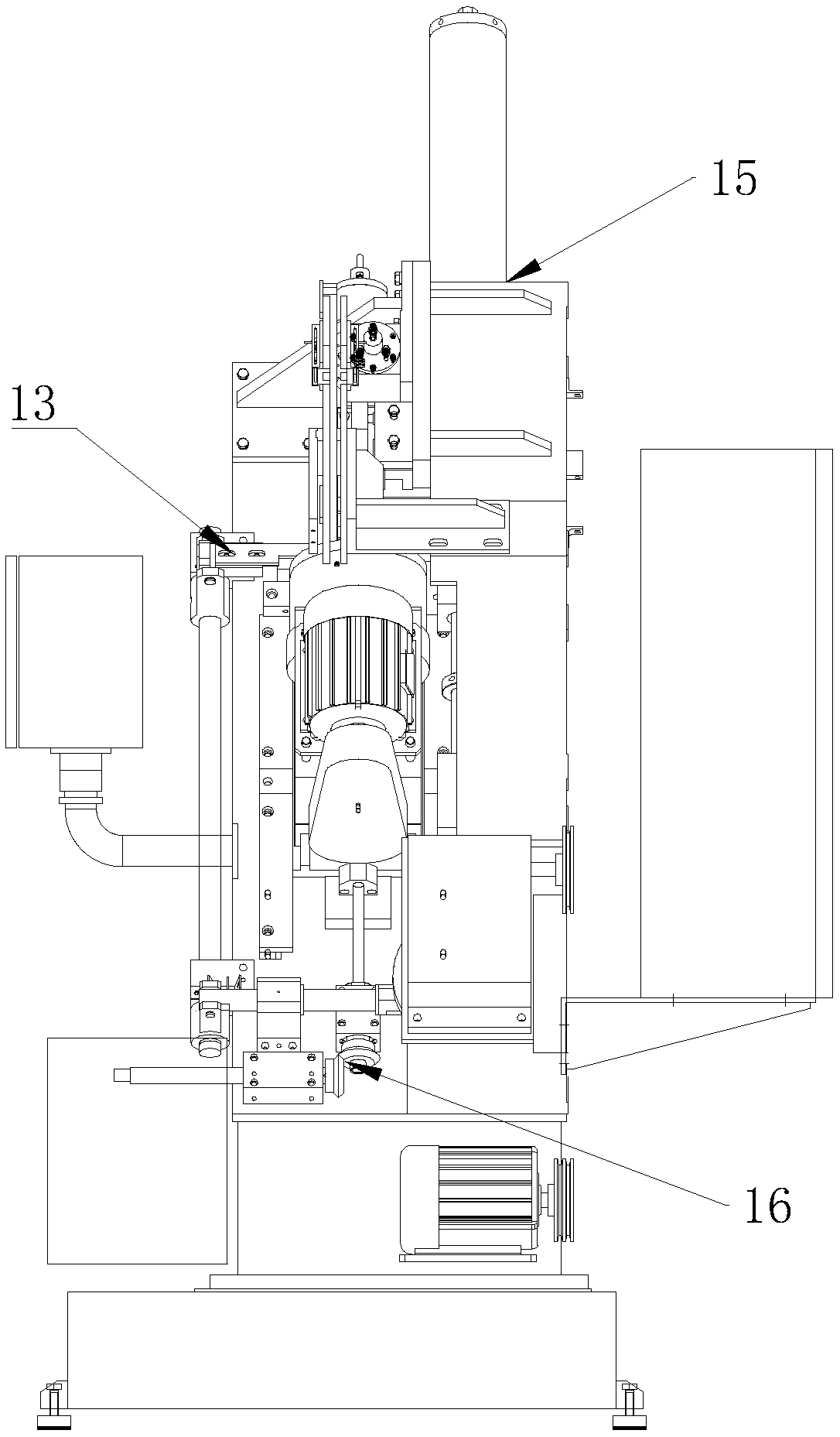

[0014] Such as figure 1 As shown, a cam-type high-speed front end processing machine includes a base 1, on which is provided an inclined bed 2, and the inclined bed 2 is provided with a feeding mechanism, a clamping mechanism, a sliding head and A discharging mechanism, the feeding mechanism includes a feeding plate 3, the clamping mechanism includes a clamping block 5 disposed toward the feeding plate 3, and the head includes a first motor 6 and a power head 7 connected to the first motor 6, The power head 7 is connected with a cutting tool, the base 1 is provided with a second motor 8, and the inclined bed 2 is provided with a reducer 9, and the second motor 8 drives the reducer through a timing belt and a timing wheel 9 rotates, the speed reducer 9 is connected with a feed cam 10 and a feed cam 11, the feed cam 10 is connected with a guide wheel 12, the guide wheel 12 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com