A Compensation Method for Zero Point Error of Driven Joints of Five Degrees of Freedom Hybrid Robot

A zero-point error and compensation method technology, which is applied in the field of rapid compensation of zero-point error of drive joints of five-degree-of-freedom hybrid processing robots, can solve problems such as numerous parameters to be identified, inaccurate identification, and complex identification models, and achieve a simple and efficient calibration process , fewer parameters to be identified, and a simpler identification model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0056] This embodiment is aimed at a fast compensation method for the zero-point error of the driving joint of a five-degree-of-freedom hybrid robot with a rotating bracket disclosed in Chinese patent publication No. CN104985596A.

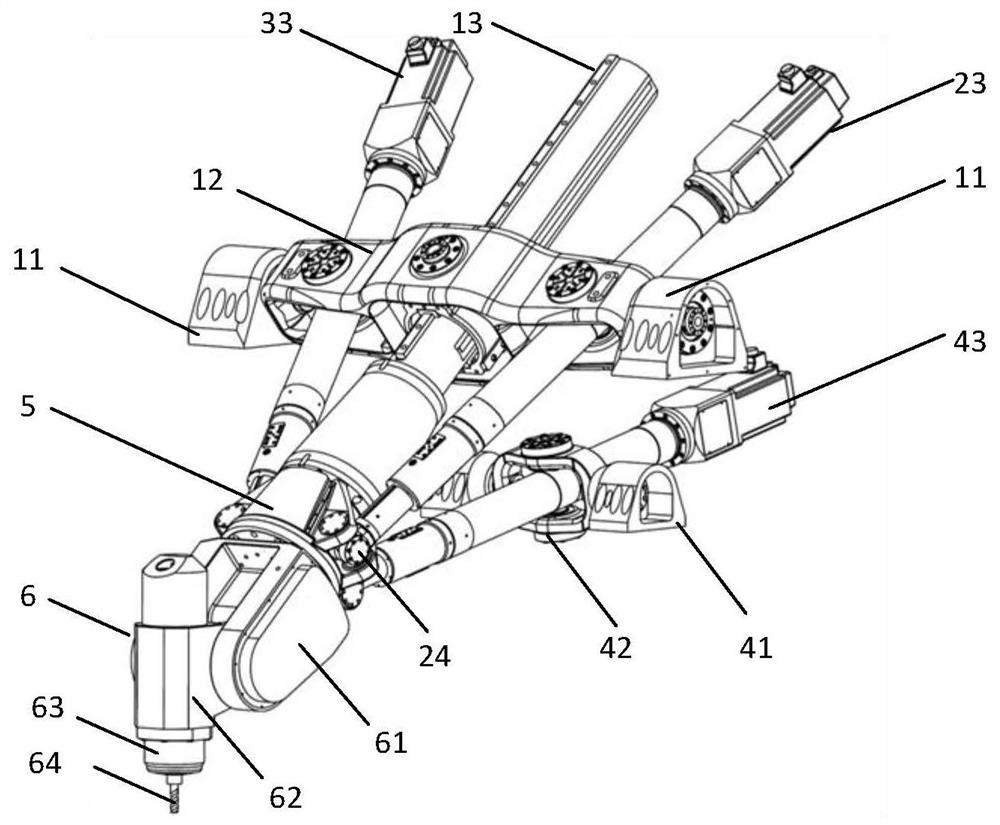

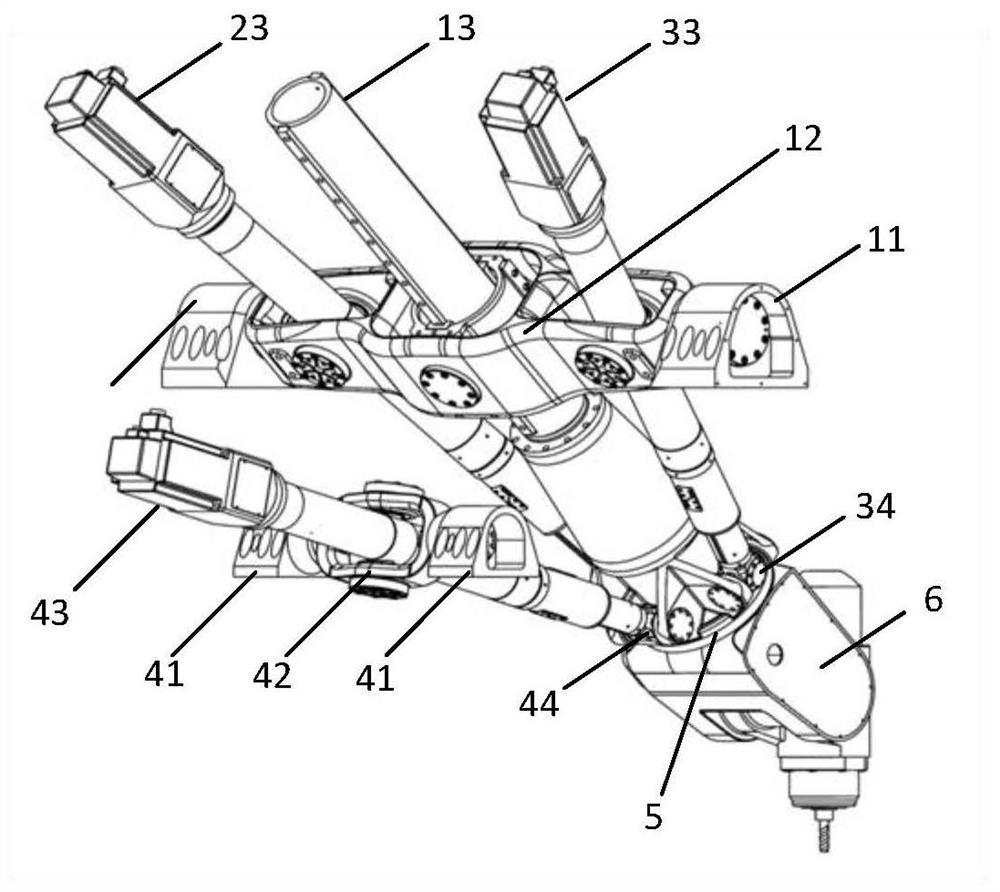

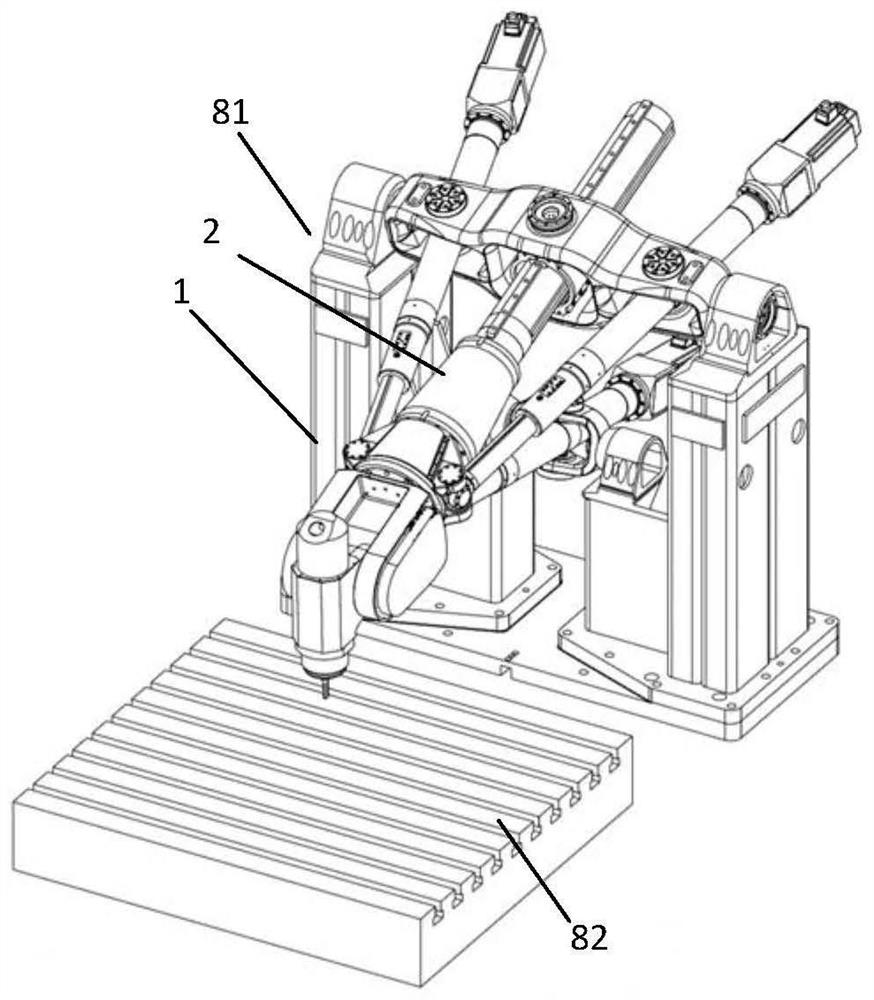

[0057] Attached below figure 1 And attached figure 2 The structure of the five-degree-of-freedom hybrid configuration equipment disclosed in CN104985596A is briefly described. The five-degree-of-freedom hybrid robot 1 is composed of a three-degree-of-freedom parallel mechanism with one translation and two rotations and a series-connected rotor with two rotational degrees of freedom connected in series, and the series-connected rotor 6 is fixedly connected to the parallel mechanism moving platform. The tandem rotary head 6 connected in series at the end of the moving platform 5 is a two-degree-of-freedom A / C sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com