Assemble integral type profiled steel plate-concrete composite slab and installation and use method thereof

A profiled steel plate, integral technology, applied in the direction of floor slabs, building components, buildings, etc., can solve problems such as the self-weight of the floor, and achieve the effects of large unsupported span, convenient construction, and steel saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

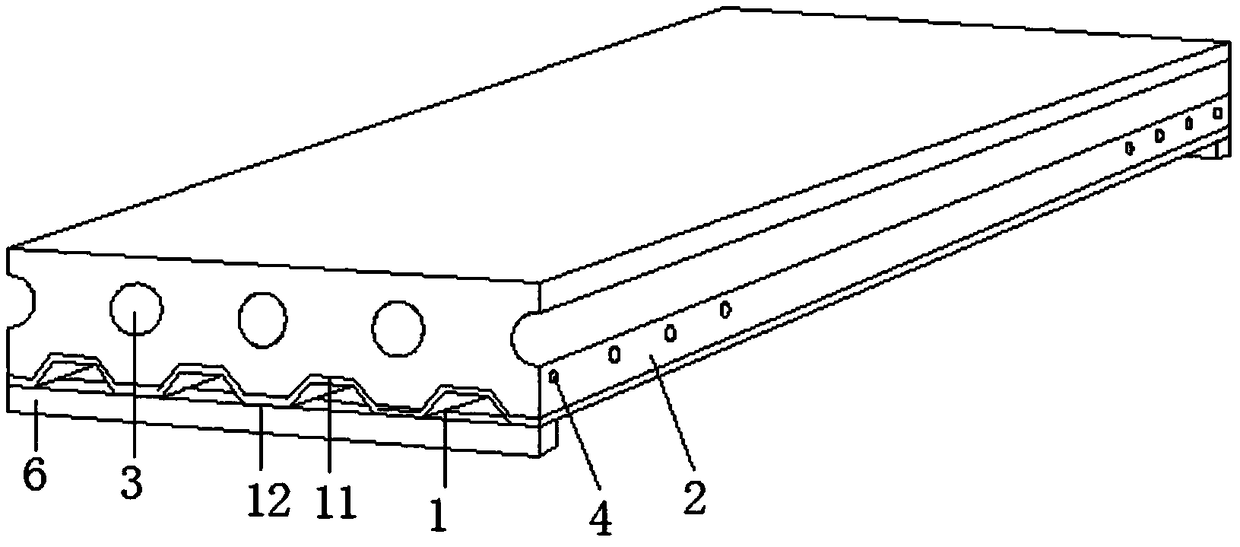

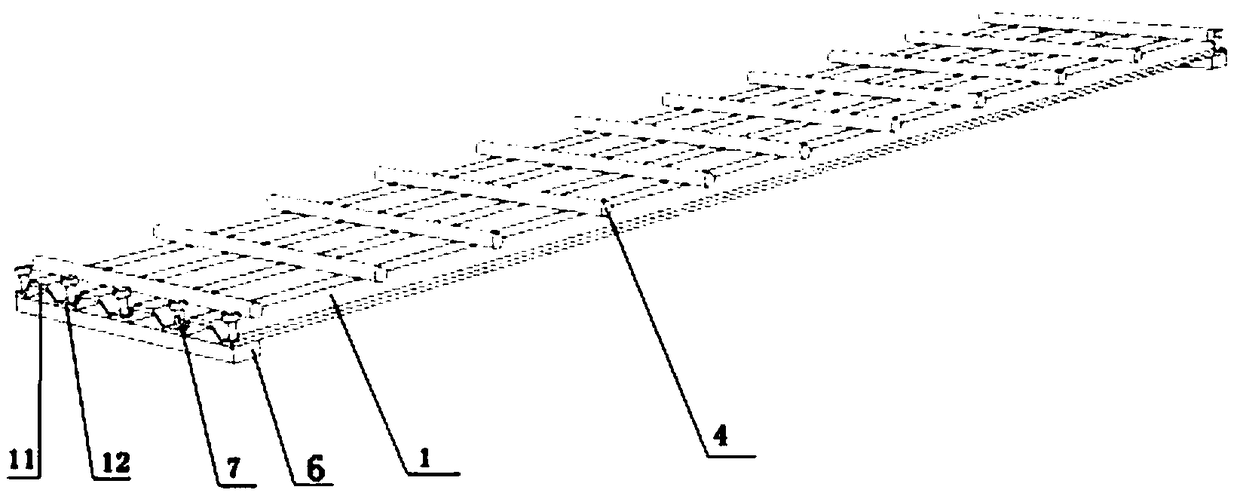

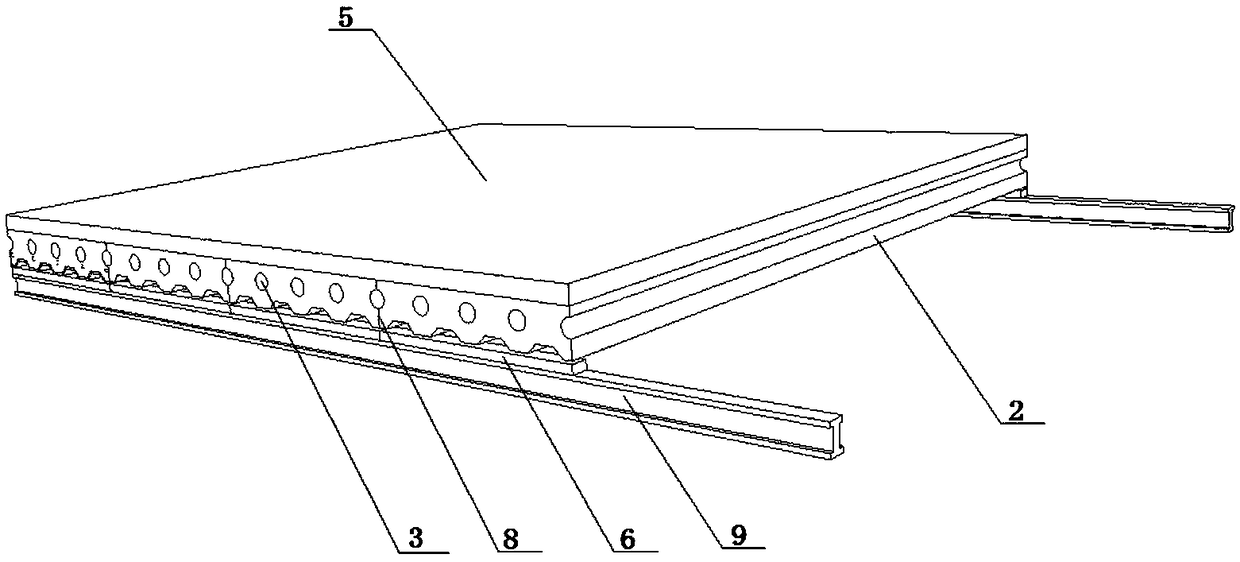

[0041] refer to figure 1 , figure 2 , the present invention includes a profiled steel plate 1, the profiled steel plate 1 includes a flange 11 and a concave rib 12, and the flange 11 and the concave rib 12 are evenly connected at intervals. In this embodiment, the profiled steel plate 1 is YX50-180- 720 open-shaped profiled steel plate, the lower ends of the profiled steel plate 1 are provided with 10mm thick steel plate 6, which facilitates better welding of the composite plate and the steel beam of the staggered truss structure. The profiled steel plate 1 is welded to the steel plate 6 through the concave rib 12 through the stud 7, wherein the stud 7 is a cylindrical head welding stud, and the material matches the material of the profiled steel plate. Galvanized coating film and antirust paint on the contact surface of the steel plate 6 to ensure the quality of the weld seam between the top surface of the steel plate 6 and the stud 7; the flange 11 is welded with steel bar...

Embodiment 2

[0043] Example 2: Reference figure 1 , 2, In this embodiment, only the lightweight core 3 is different, and the lightweight core 3 is a hollow body made of polystyrene plastic, and the rest of the structures are the same as in Example 1.

Embodiment 3

[0044] Example 3: Reference figure 1 , 2 , In this embodiment, only the lightweight core 3 is different, and the lightweight core 3 is a lightweight hollow body made of perlite light material, and the rest of the structure is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com