Fireproof door core board with three-dimensional network support and manufacturing method thereof

A fire door core board, three-dimensional mesh technology, used in fire doors, door leaves, windows/doors, etc., can solve the problems of fire door strength and thermal barrier incompatibility, avoid pulverization and shedding, simplify production process, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The accompanying drawings are for illustrative purposes only and cannot be construed as limiting the patent;

[0024] In order to better illustrate this embodiment, some parts in the drawings will be omitted, enlarged or reduced, and do not represent the size of the actual product;

[0025] For those skilled in the art, it is understandable that some well-known structures and descriptions thereof may be omitted in the drawings.

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

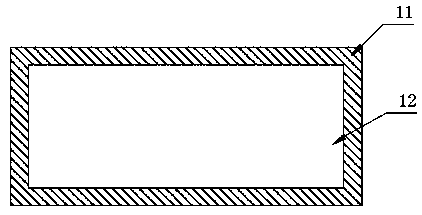

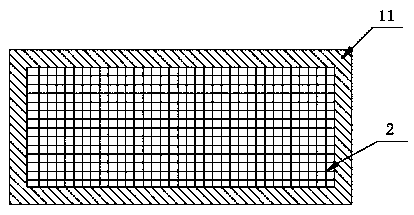

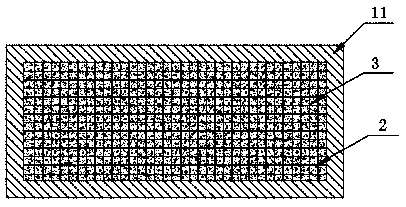

[0027] This embodiment is a fire door core board with a three-dimensional mesh bracket. The main body of the fire door core board is provided with a three-dimensional mesh bracket 2 that is as large as the fire door core board and has a square hole shape. The three-dimensional mesh bracket 2 Made of cardboard.

[0028] The specific production method is as follows:

[0029] Step 1: Make an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com