High-brightness surface light source and plant culture rack using high-brightness surface light source

A high-brightness, surface light source technology, applied in the field of plant cultivation, can solve the problems of difficulty in ensuring the growth rate and growth cycle of plants, difficulty in achieving light mixing effect, uneven plant quality, etc., so as to shorten the growth cycle of plants and improve space utilization. rate and heat dissipation effect, good light mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] For the convenience of description, the directions mentioned below are explained as follows: the up and down directions mentioned below are related to figure 2 with Figure 5 The up and down direction of itself is the same.

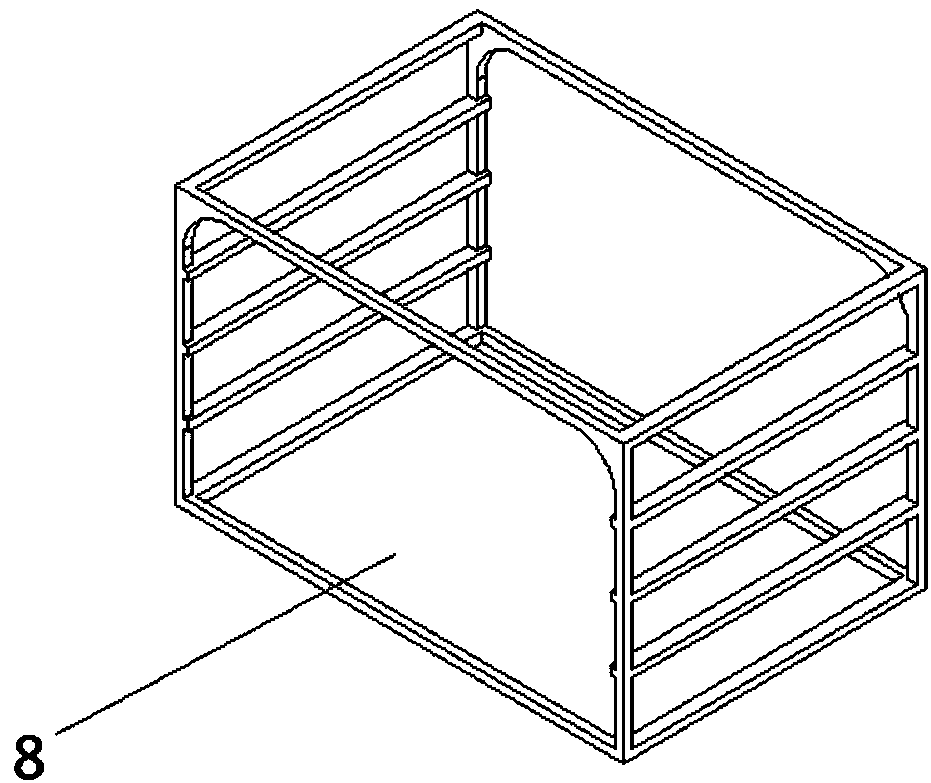

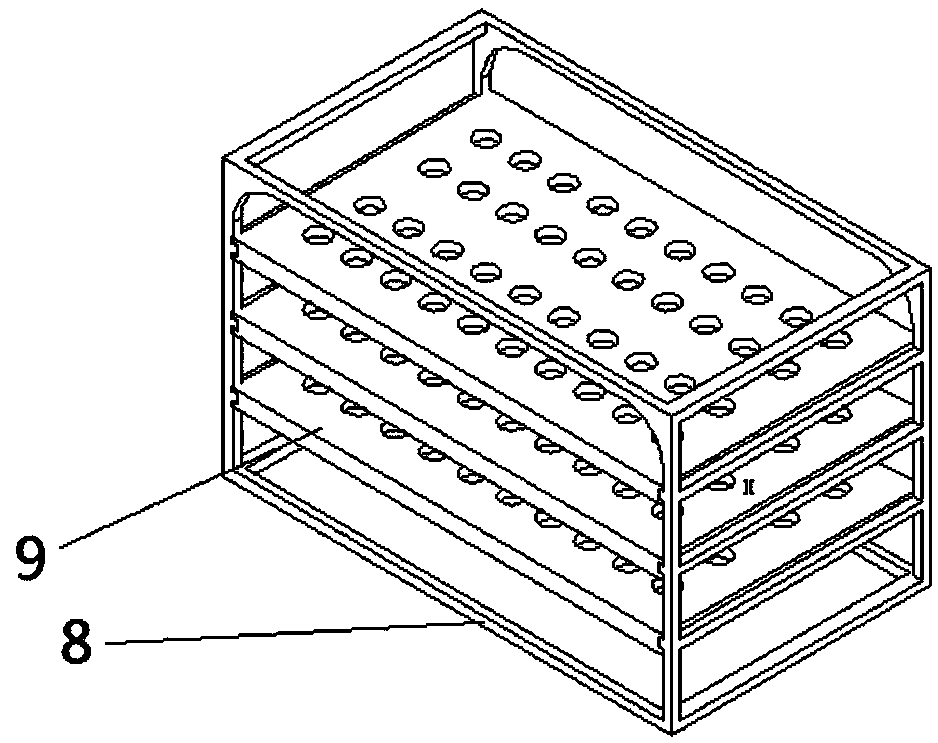

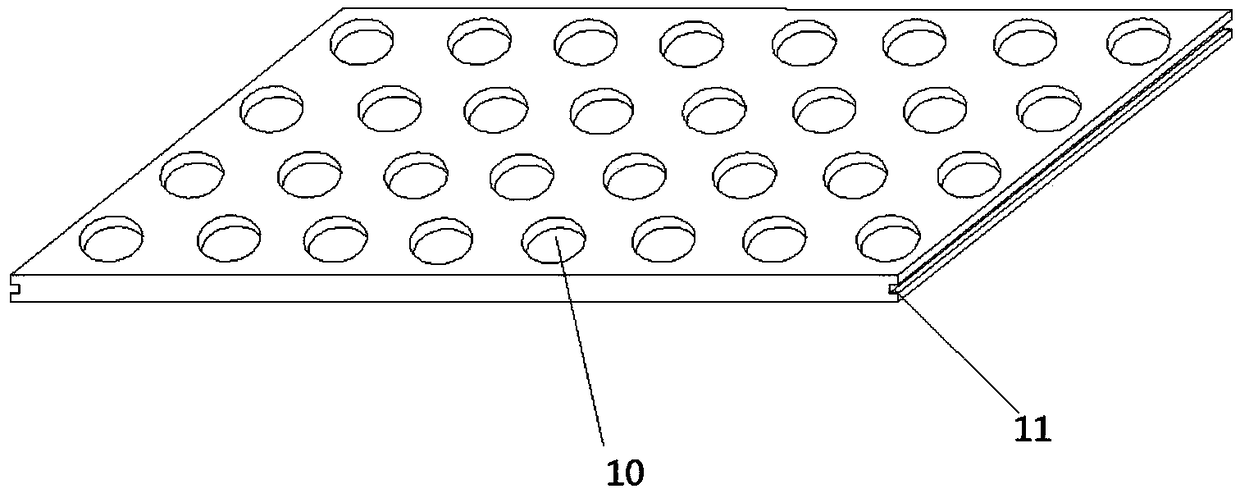

[0030] Such as figure 1 , image 3 As shown, it is a plant cultivation rack using a high-brightness surface light source of the present invention, and the plant cultivation rack includes an external frame, a plant cultivation partition and a high-brightness surface light source. Among them, the bottom of the outer frame has a pulley that can be braked safely, which is convenient for the movement and fixation of the culture frame. There are several pairs of parallel protrusions on the left and right side walls inside the outer frame, such as figure 1 As shown, it can be used for plant cultivation partitions and high-brightnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com