A multi-return gas boiler

A gas-fired boiler and multi-return technology, which is applied to steam boilers, steam boiler accessories, boiler cleaning devices, etc., can solve the problems of low heating efficiency of boilers, achieve the effects of improving heating efficiency, increasing flow, and facilitating timely maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] In the description of the present invention, it should be noted that the terms "first", "second", and "third" are used for description purposes only, and should not be understood as indicating or implying relative importance.

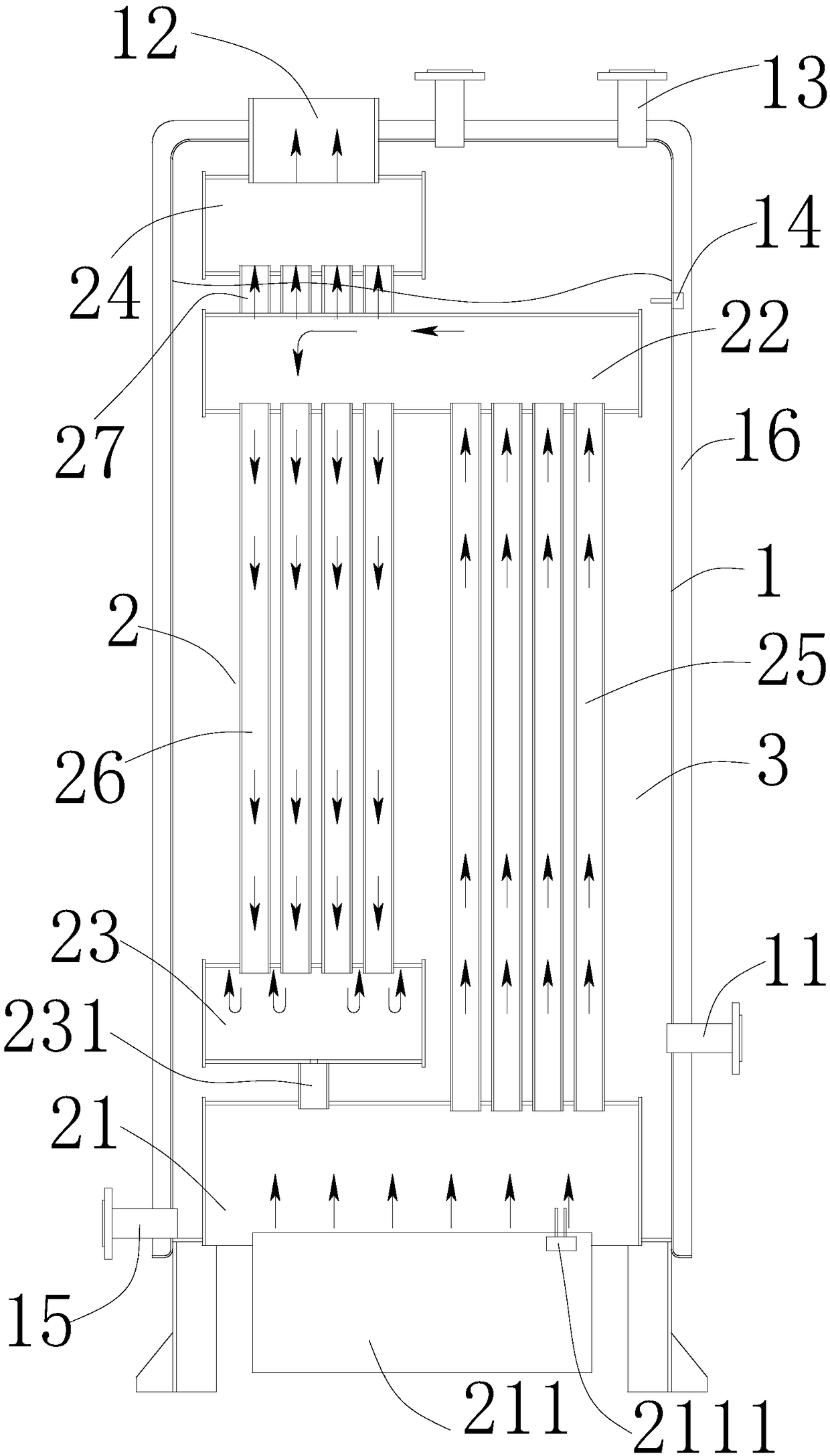

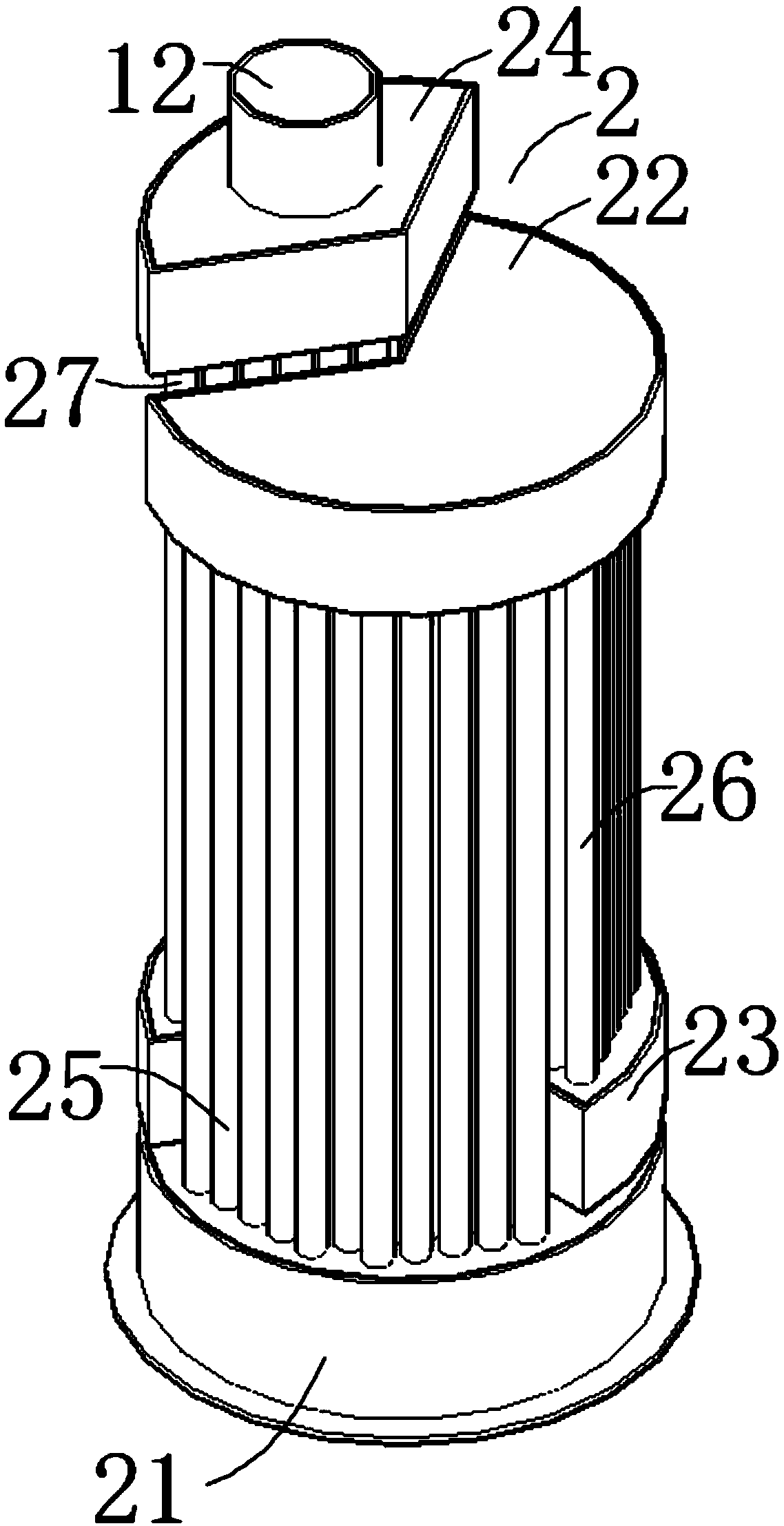

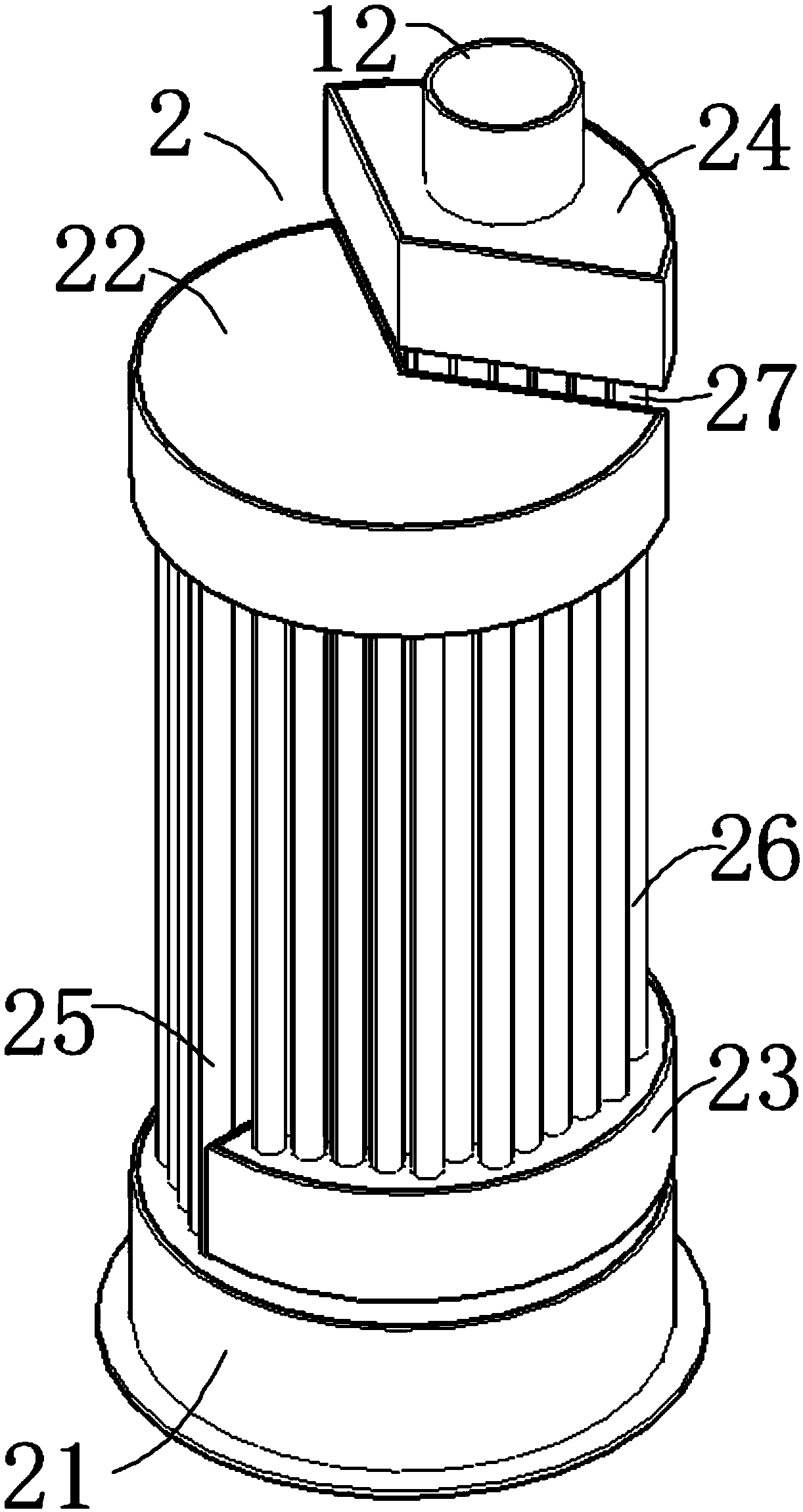

[0033] Such as figure 1 As shown, a multi-return gas boiler includes a casing 1, a heating device 2 arranged in the casing 1, a water storage space 3 is formed between the heating device 2 and the casing 1, and the casing 1 includes a water inlet 11 and a smoke exhaust port. 12. The steam outlet 13 located at the top of the casing 1 .

[0034] key reference Figure 2-7 In this embodiment, the heating device 2 includes a combustion chamber 21 arranged at the inner bottom of the casing 1, a first smoke collection box 22 located above the combustion chamber 21, a second collection box located between the combustion chamber 21 and the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com