Sound velocity-attenuation coefficient integrated detection method for polymer

A technology of attenuation coefficient and detection method, which is applied in the detection field to achieve the effects of convenient calculation, easy online monitoring and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the present invention more clearly understood, the present invention will be further described below according to specific examples and accompanying drawings of the present invention.

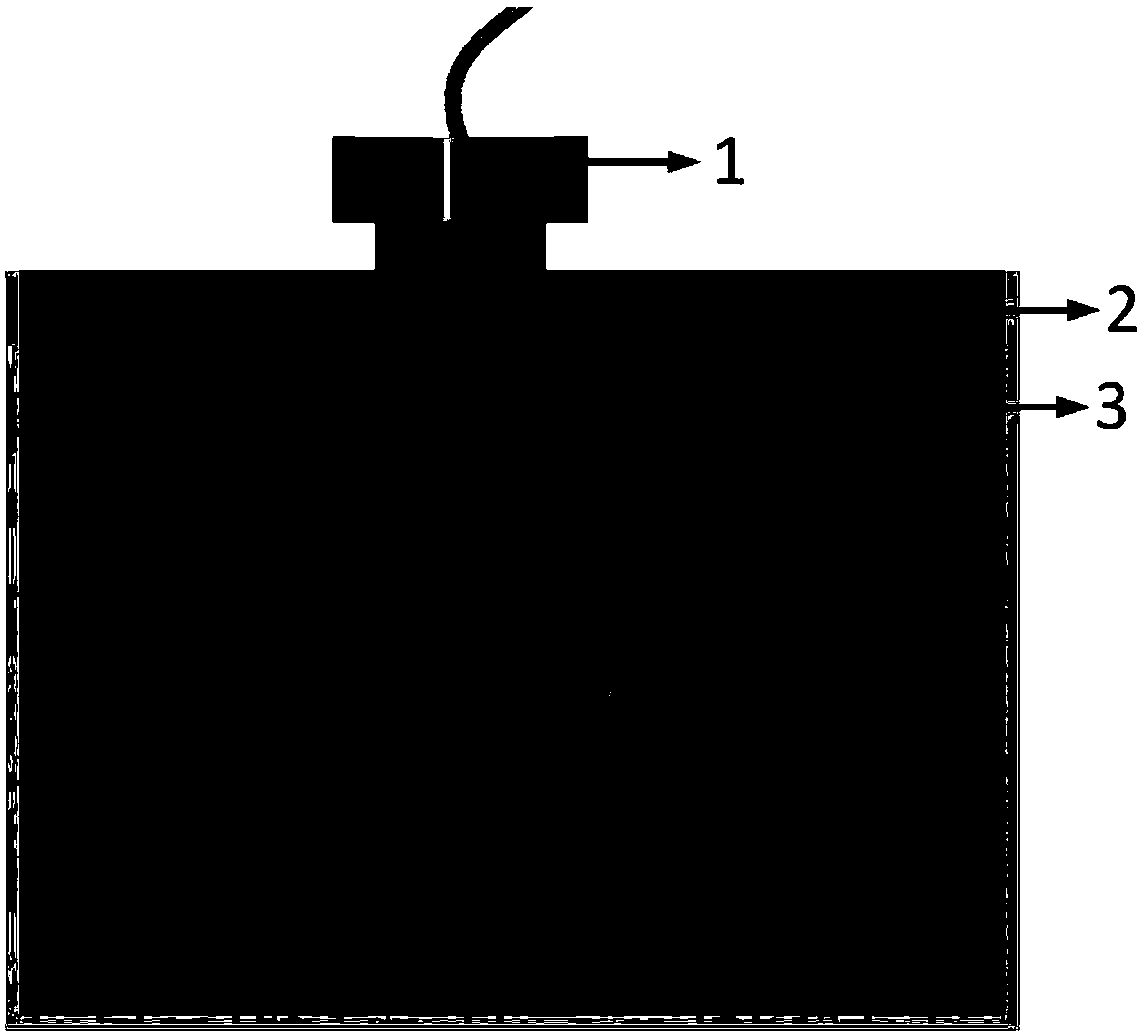

[0044] Such as figure 1 Shown is the schematic diagram of ultrasonic detection of the present invention, including ultrasonic probe 1, container 2, water 3, and sample 4.

[0045] Ultrasonic testing methods for plastic parts, including:

[0046] Place the sample in a container filled with water.

[0047] Use a water immersion ultrasonic probe to emit pulse waves with a certain center frequency. When testing, ensure that the ultrasonic probe is facing the upper surface of the sample.

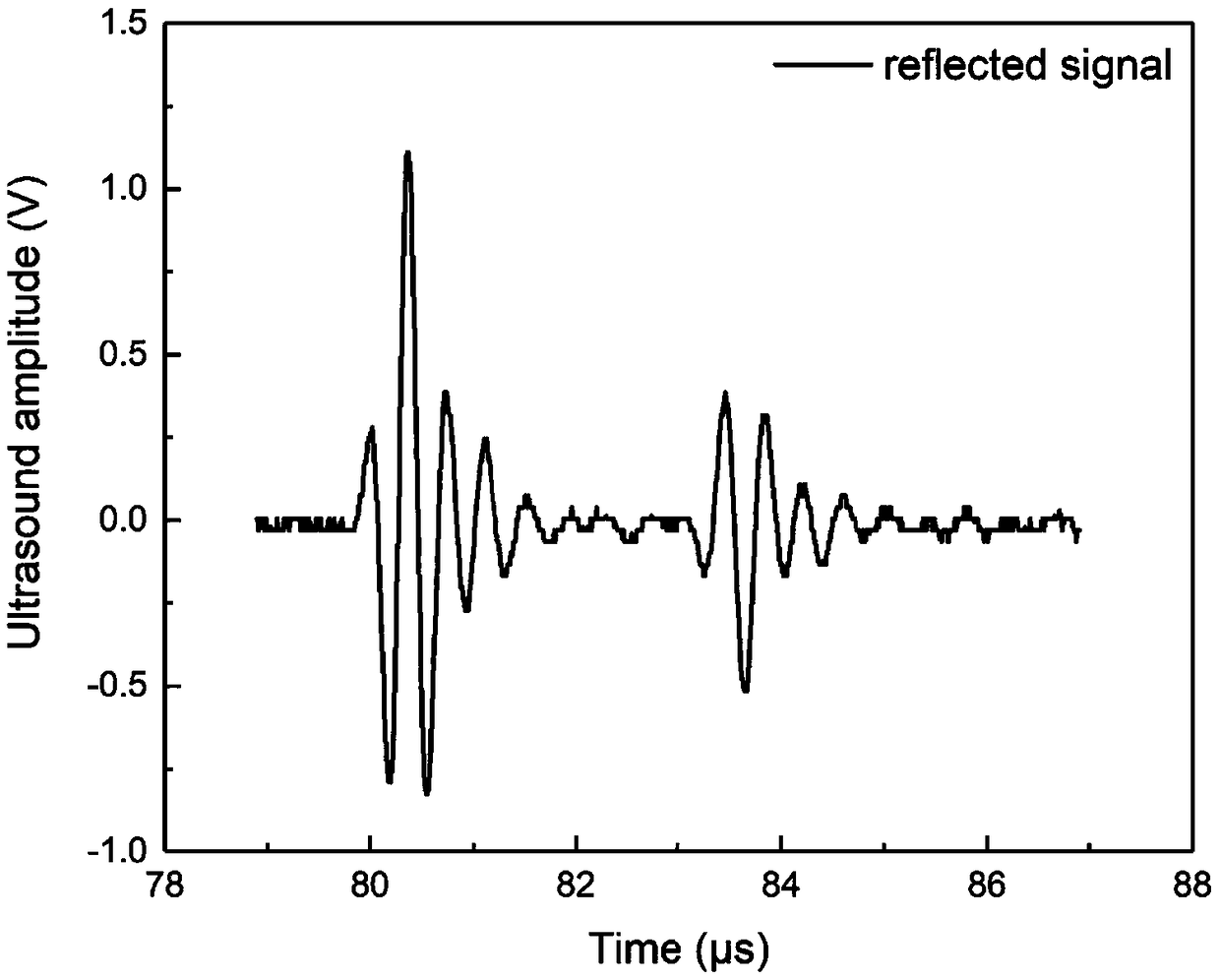

[0048] Use an oscilloscope to collect the reflected echoes from the upper and lower surfaces of the receiving sample.

[0049] Calculate the frequency spectrum of the reflected echoes from the upper and lower surfaces of the sample according to the Fourier transform.

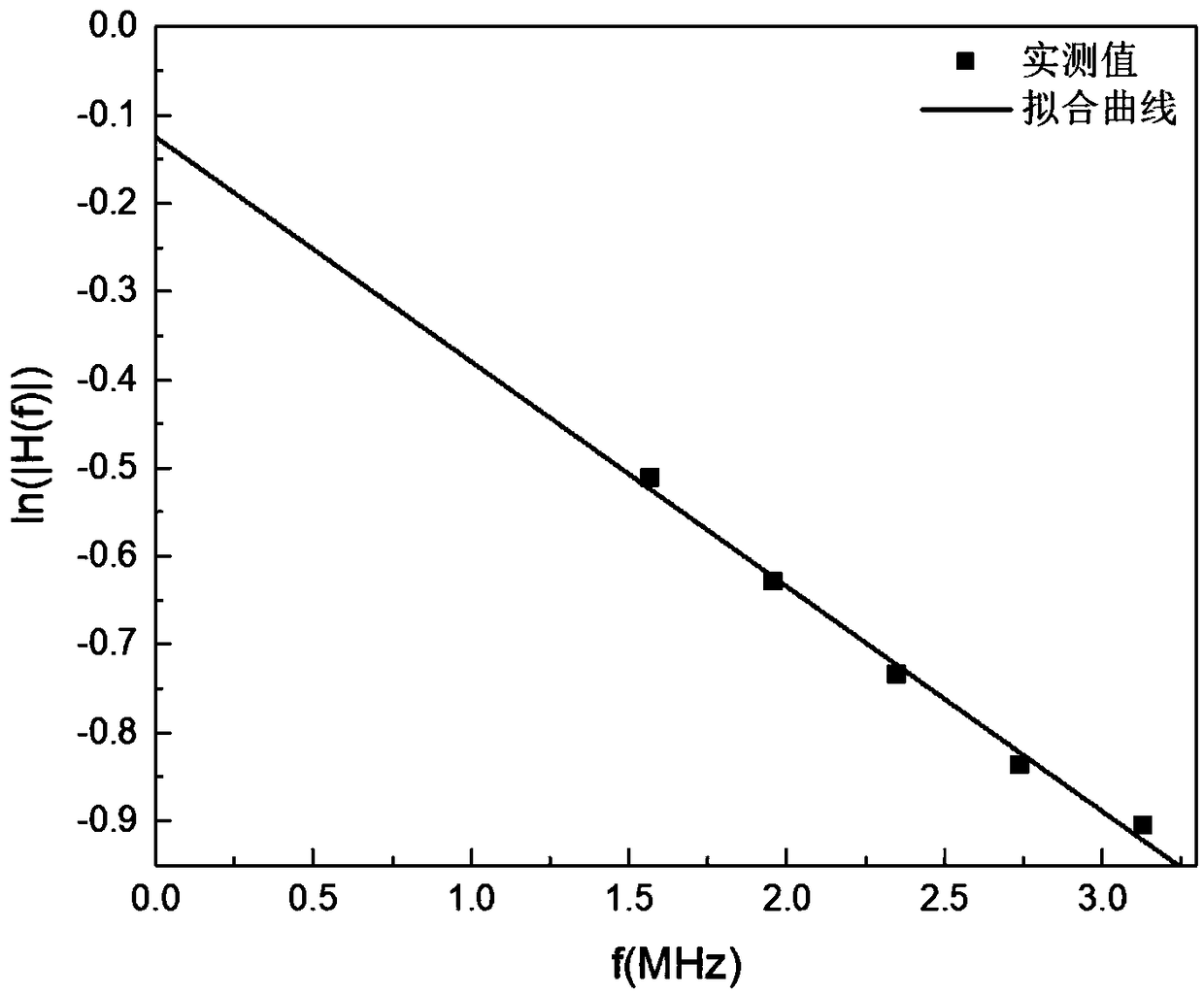

[0050] Make a gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com