Method for calculating failure rate of insulation oil degradation of transformer

A technology for transformer insulating oil and transformer faults, which is applied in the field of calculation of transformer insulating oil deterioration failure rate, and can solve problems such as complex interrelationships and large quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

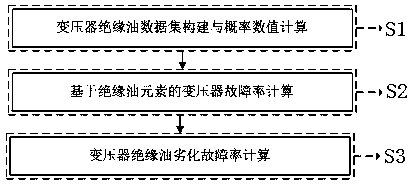

[0024] like figure 1 As shown, a method for calculating the failure rate of transformer insulating oil degradation. The transformer failure depends on the abnormal change characteristics of the transformer insulating oil. The transformer failure probability is determined by the abnormal change characteristic value of the transformer insulating oil according to the probability principle. The parameters involved in the evaluation include: oil medium loss, water content in oil, gas content in oil, oil breakdown voltage, oil volume resistivity, oil conductivity, acid value in oil, oil breakdown voltage, total acid value in oil, oil in Furfural content and oil color; perform cluster processing on the characteristic values of abnormal changes in transformer insulating oil with random uncertainty, and construct a calculation function for the deterioration failure rate of transformer insulating oil, including the following steps;

[0025] S1: Transformer insulating oil data set cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com