Permanent-magnet speed-adjustable motor and control method thereof

A permanent magnet speed regulation and motor side technology, applied in the direction of permanent magnet clutch/brake, control system, control electromechanical brake, etc., can solve the problems of poor control response speed and corresponding precision, high working temperature, slow speed, etc., to achieve Improved reliability and safety, faster control response, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

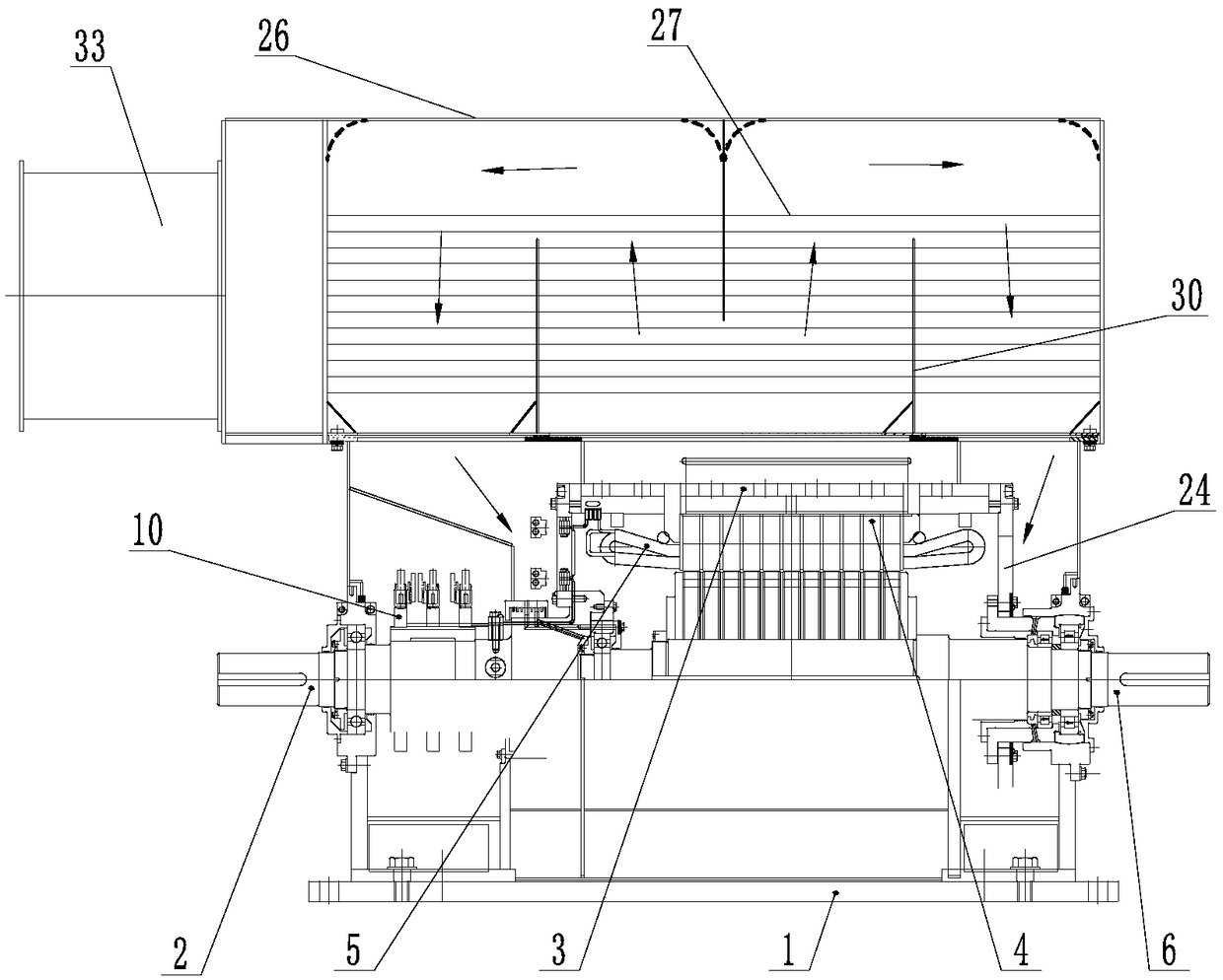

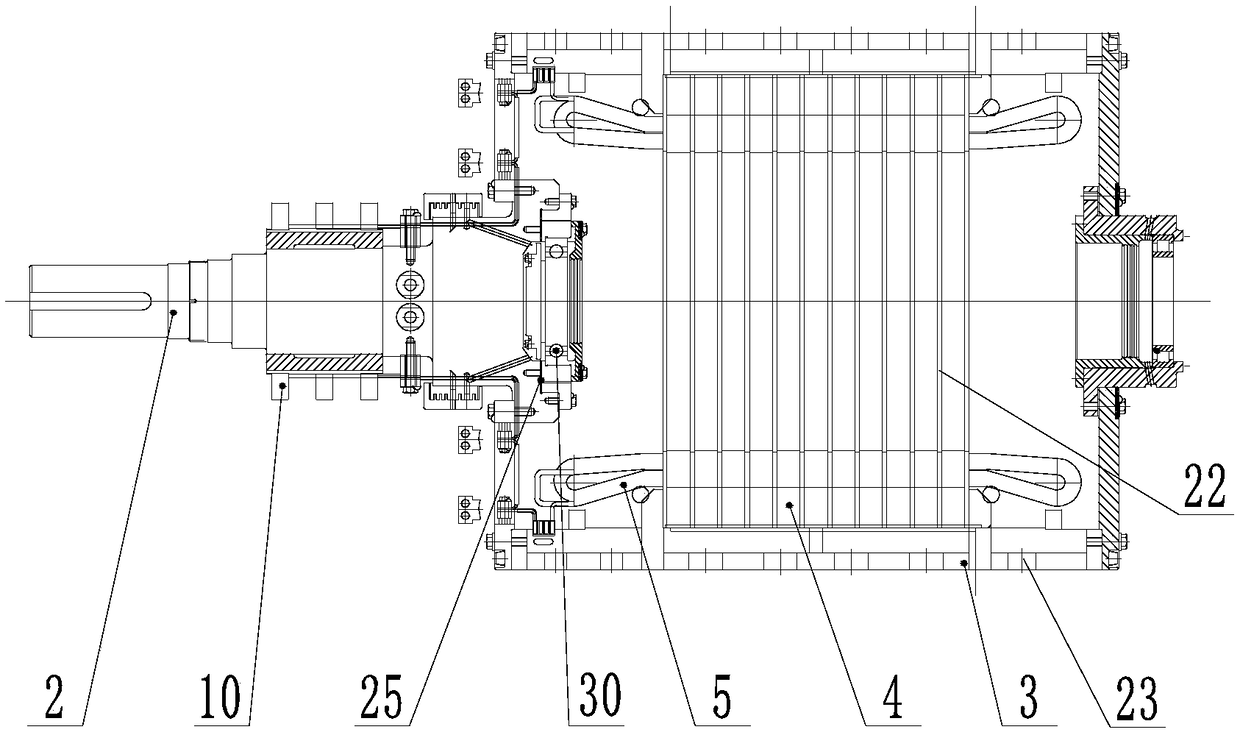

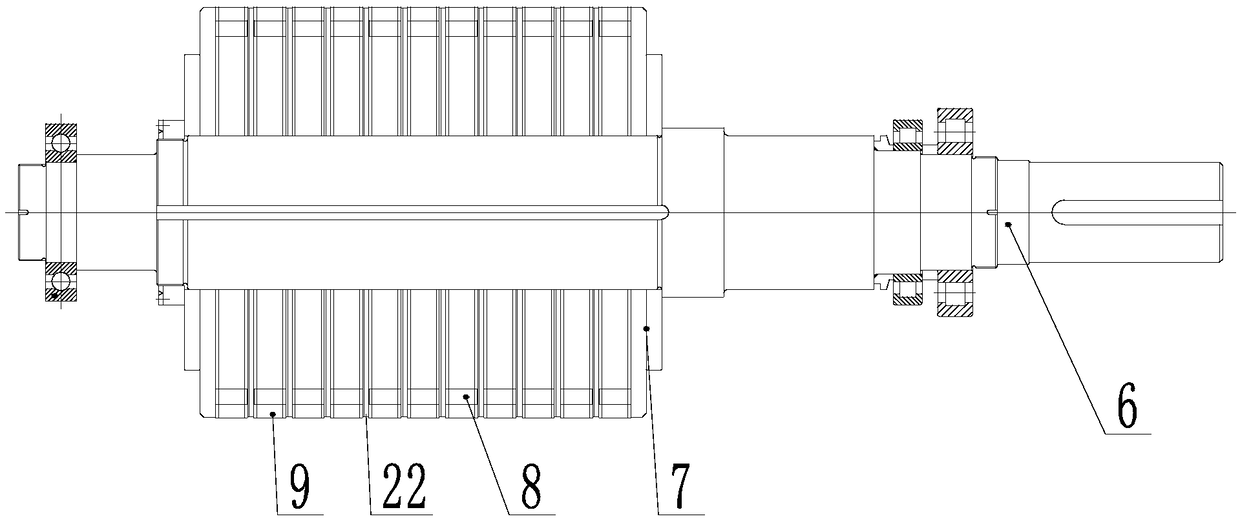

[0036]A permanent magnet speed-regulating motor and a control method thereof provided in this embodiment include a motor base 1, an outer rotor assembly and an inner rotor assembly are respectively provided on the motor base 1 and at both ends along its length direction through bearings, The outer rotor assembly includes a first rotating shaft 2 on which a collector ring 10 is arranged, and a cylindrical iron core holder 3 is arranged on one end of the first rotating shaft 2 inside the motor base 1 , the outer rotor core 4 and multiple sets of induction coils 5 matched with the outer rotor core 4 are arranged in the middle of the iron core holder 3, the output ends of the induction coils 5 are connected to the slip ring 10, and The number of groups of the induction coils 5 is 6 groups, the number of the slip rings 10 is 6, and 3 groups of non-adjacent induction coils 5 form a three-phase potential, and there are 2 three-phase potentials in total;

[0037] The inner rotor assem...

Embodiment 2

[0054] This embodiment discloses a permanent magnet speed-regulating motor. This technical solution is the same as the technical solution of the embodiment, wherein the number of groups of induction coils 5 is 12, the number of said slip rings 10 is 12, and every three groups of induction The coil 5 forms a three-phase potential, and there are 4 three-phase potentials in total, and the radial unilateral gap between the permanent magnet 9 and the outer rotor core 4 is 4mm, and the θ is 20°, wherein the circuit selection switch 11 and the implementation The technical solutions in Example 1 are similar and can be directly obtained by analogy;

[0055] The control method of the permanent magnet speed regulating motor is carried out in the following steps:

[0056] Step 1: Control the circuit selection switch 11 through the main controller 17, first connect the four three-phase potentials in parallel and then connect them in series with the motor side filter 12, then turn on the is...

Embodiment 3

[0061] This embodiment discloses a permanent magnet speed-regulating motor. This technical solution is the same as that of the embodiment, wherein the number of induction coils 5 is 18, and the number of collector rings 10 is 18. Every three groups of induction The coil 5 forms a three-phase potential, and there are 6 three-phase potentials in total, and the radial unilateral gap between the permanent magnet 9 and the outer rotor core 4 is 5mm, and the θ is 30°, wherein the circuit selection switch 11 and the implementation The technical solutions in Example 1 are similar and can be directly obtained by analogy;

[0062] The control method of the permanent magnet speed regulating motor is carried out in the following steps:

[0063] Step 1: Control the circuit selection switch 11 through the main controller 17, first connect the six three-phase potentials in parallel and then connect them in series with the motor side filter 12, then turn on the isolating switch 16, and connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com