Processing technology of preboiled rice

A processing technology and a technology for parboiled rice, which is applied to the processing technology field of parboiled rice, can solve the problems of low processing efficiency, complex process and low production quality, and achieve the effect of improving the processing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

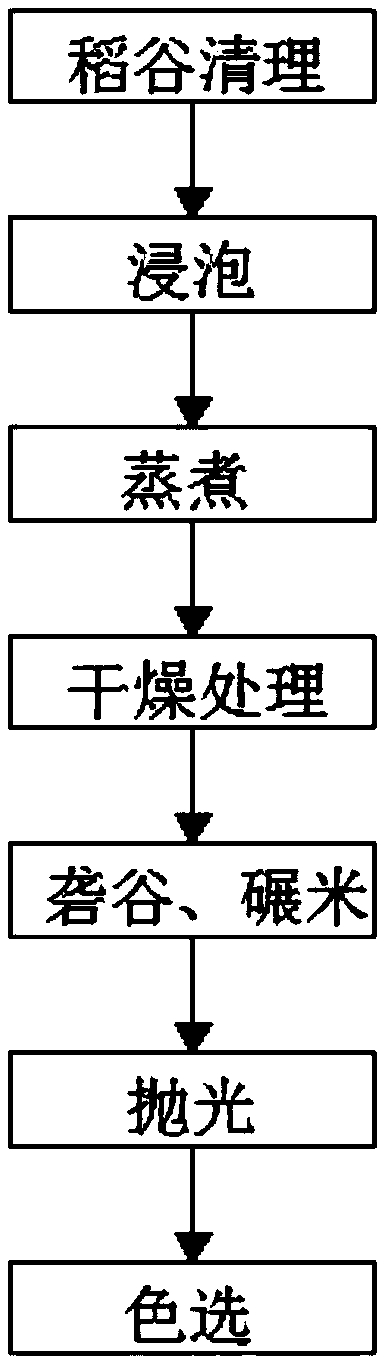

Image

Examples

Embodiment 1

[0049] (1), paddy cleaning:

[0050] Remove impurities from raw rice, remove weeds, stones, and soil particles, and remove incomplete grains from raw rice;

[0051] (2), soaking:

[0052] Heat the water temperature to 45°C, pressurize to 0.4MPa, add the cleaned rice, soak for 40 minutes, adjust the water temperature to 35°C, adjust the pressure to 3MPa, until the water absorption rate of the rice reaches 37%;

[0053] (3), cooking:

[0054] Steaming the soaked rice;

[0055] (4), drying treatment:

[0056] Send the cooked rice into the drier, heat and dry to a water content of 17%, and then cool to room temperature;

[0057] (5), husking and rice milling:

[0058] Use a rice huller to dehull, after husking, separate the paddy, and the prepared parboiled brown rice is sent to the rice mill for whitening;

[0059] (6), polishing:

[0060] Using a polishing machine to polish the parboiled rice;

[0061] (7), color sorting

[0062] A small amount of black-grained rice, bl...

Embodiment 2

[0067] (1), paddy cleaning:

[0068] Remove impurities from the raw grain rice, remove weeds, stones, soil particles in the raw grain rice, and remove incomplete grains in the raw grain rice;

[0069] (2), soaking:

[0070] Heat the water temperature to 40°C, pressurize to 0.4MPa, add the cleaned rice, soak for 40 minutes, adjust the water temperature to 30°C, adjust the pressure to 0.15MPa, until the water absorption rate of the rice reaches 36%;

[0071] (3), cooking:

[0072] Cooking the soaked rice;

[0073] (4), drying treatment:

[0074] Send the cooked rice into the drier, heat and dry to a water content of 16%, and then cool to room temperature;

[0075] (5), husking and rice milling:

[0076] Use a rice huller to dehull, after husking, separate the paddy, and the prepared parboiled brown rice is sent to the rice mill for whitening;

[0077] (6), polishing:

[0078] Using a polishing machine to polish the parboiled rice;

[0079] (7), color sorting

[0080] A sm...

Embodiment 3

[0085] (1), paddy cleaning:

[0086] Remove impurities from raw rice, remove weeds, stones, and soil particles, and remove incomplete grains from raw rice;

[0087] (2), soaking:

[0088] Heat the water temperature to 50°C, pressurize to 0.4MPa, add the cleaned rice, soak for 40 minutes, adjust the water temperature to 40°C, and adjust the pressure to 4MPa until the water absorption rate of the rice reaches 38%;

[0089] (3), cooking:

[0090] Cooking the soaked rice;

[0091] (4), drying treatment:

[0092] Send the cooked rice into the drier, heat and dry to a water content of 18%, and then cool to room temperature;

[0093] (5), husking and rice milling:

[0094] Use a rice huller to dehull, after husking, separate the paddy, and the prepared parboiled brown rice is sent to the rice mill for whitening;

[0095] (6), polishing:

[0096] Using a polishing machine to polish the parboiled rice;

[0097] (7), color sorting

[0098] A small amount of black-grained rice, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com