Local anaesthesia apparatus used for anesthesiology department

A technology of local anesthesia and anesthesiology, applied in the field of anesthesia, can solve the problems of a large number of anesthetics, numbness of patients, poor anesthesia effect, etc., and achieve the effect of reducing costs, avoiding discomfort, and saving anesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

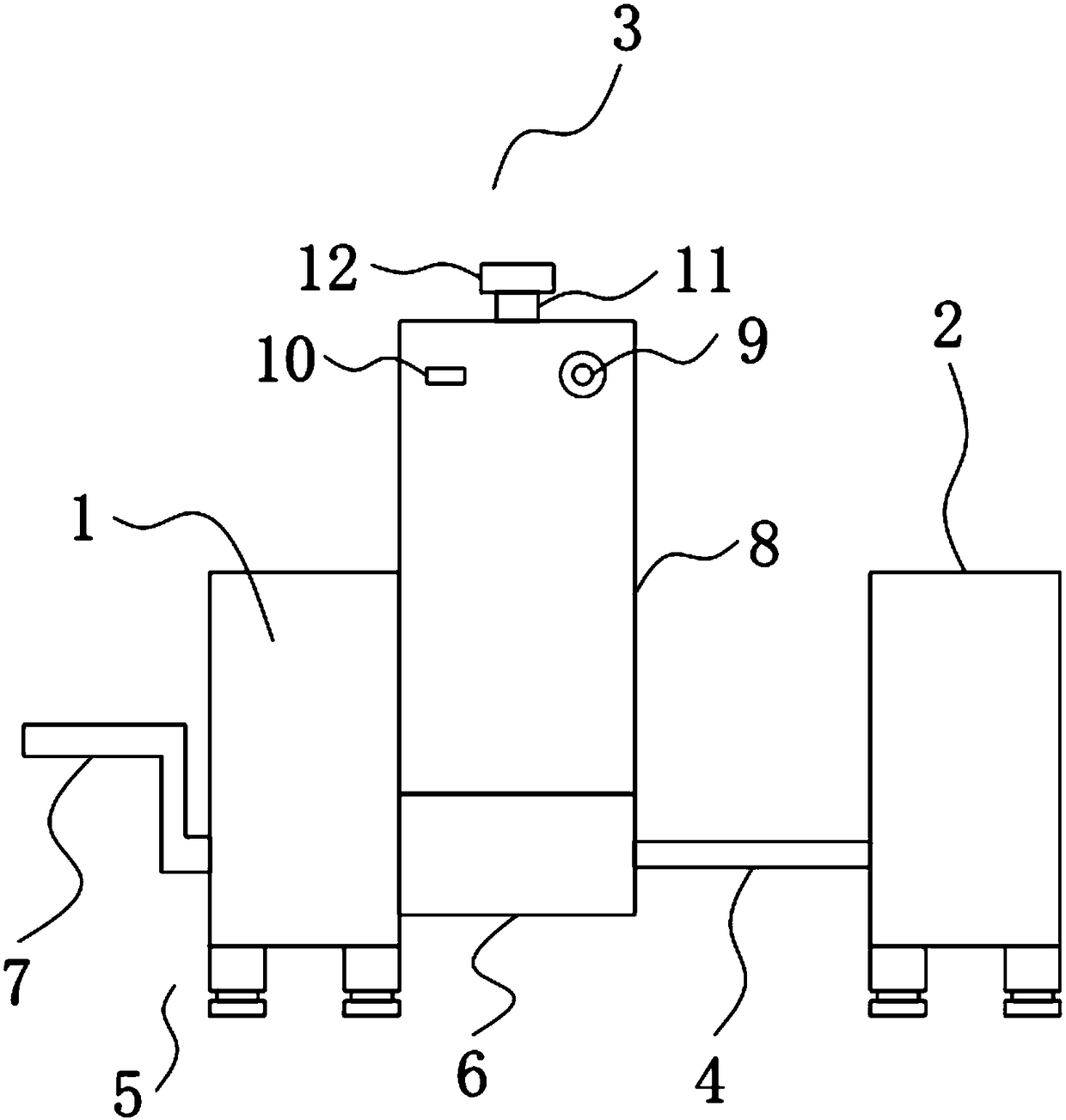

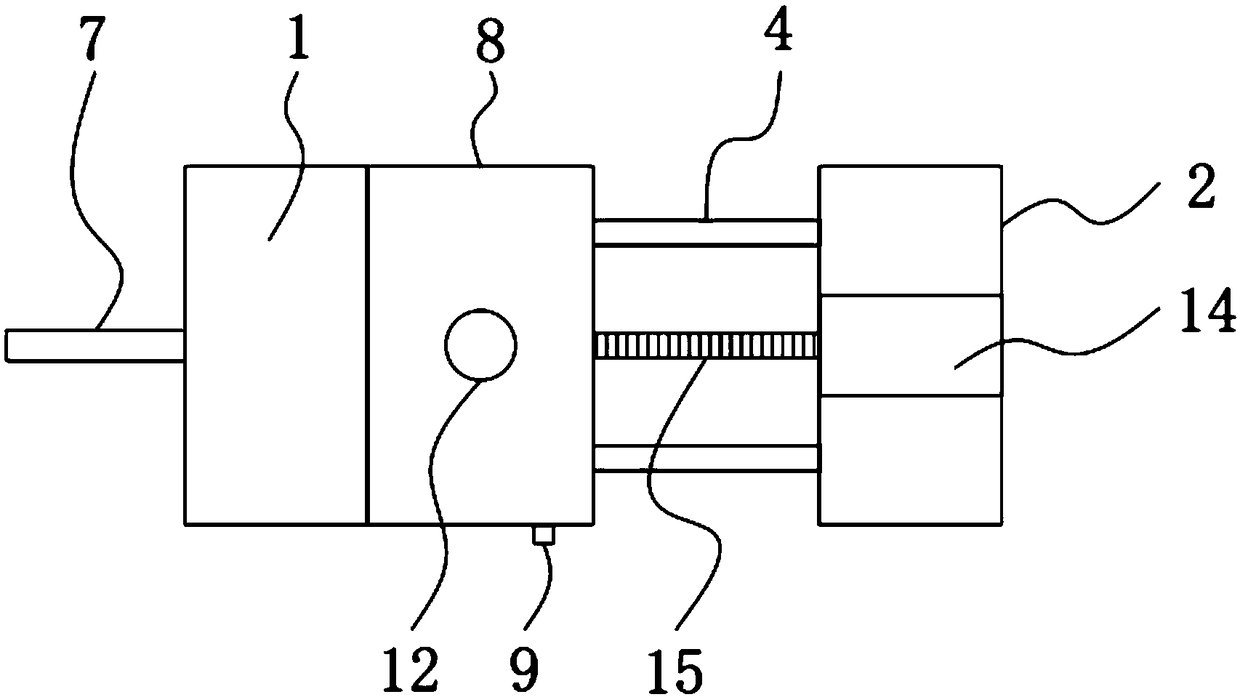

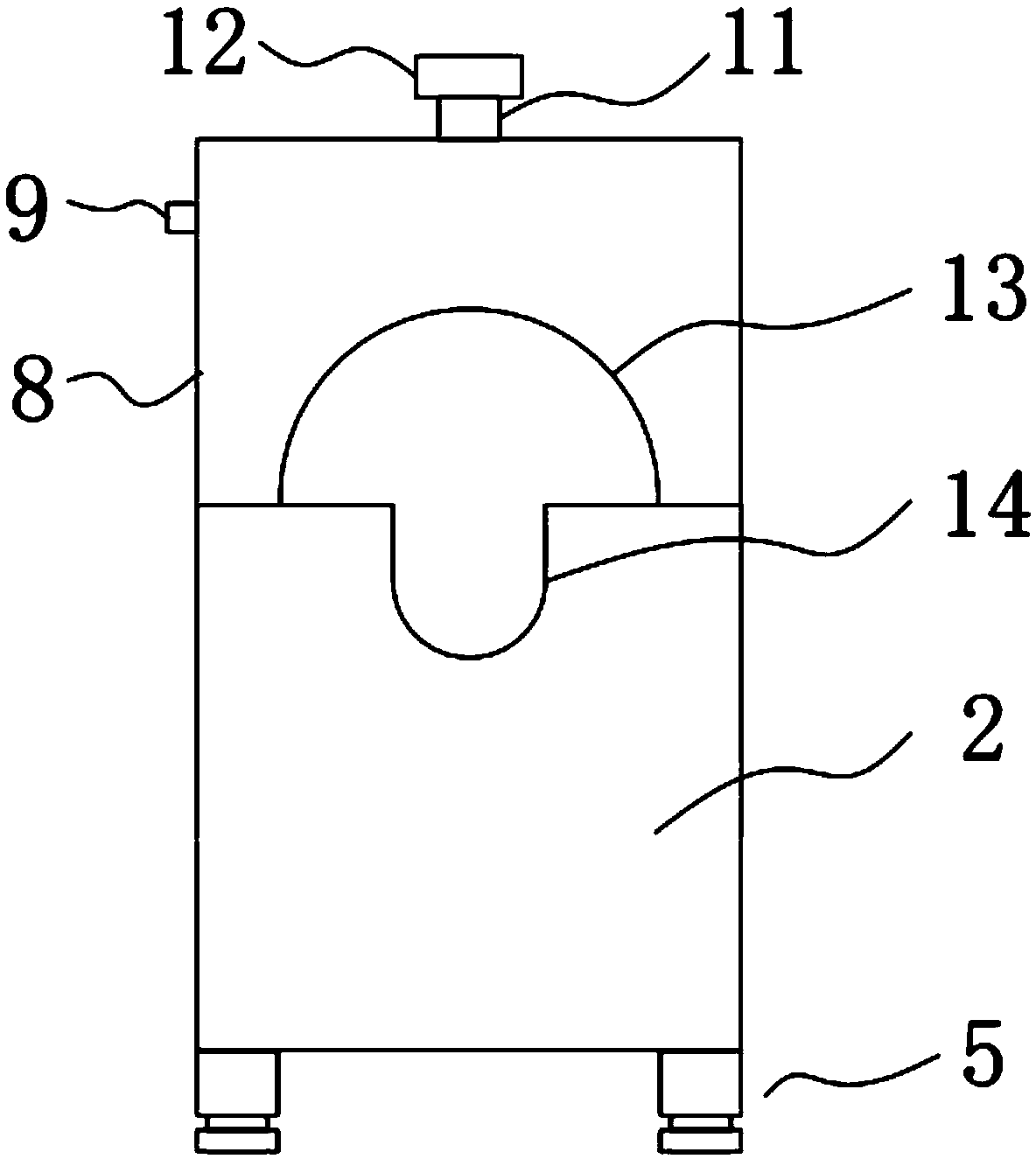

[0049] The following is attached Figure 1-8 The present invention is described in further detail.

[0050] A local anesthesia device for anesthesiology department, such as Figure 1-8 As shown, it includes a fixed seat 1 and a support seat 2, two slide bars 4 are symmetrically installed between the fixed seat 1 and the support seat 2, and a screw rod 15 is installed between the fixed seat 1 and the support seat 2 through a rolling bearing, The screw rod 15 is located between the two slide rods 4, and one end of the screw rod 15 extends to the outside of the side of the fixed base 1 away from the support base 2 and is fixedly connected with one end of the crank handle 7, and the two slide rods 4 and the wire rods The rod 15 is fitted with a support block 6 that can move along the slide bar 4, the upper part of the support block 6 is fixed with a spray anesthesia part 3, and the top of the support base 2 is provided with a groove 14 in the center;

[0051] The screw rod 15 is...

Embodiment 2

[0064] The difference from Example 1 is that the inner surface of the groove 14 is also provided with an anti-slip coating, and the anti-slip coating is prepared by the following method:

[0065] Take the following raw materials and weigh them by weight: 35 parts of epoxy resin, 20 parts of calcium carbonate powder, 60 parts of methanol, 18 parts of phenolic resin, 10 parts of titanium dioxide powder, 10 parts of zinc phosphate powder, 5 parts of diethylthiourea and paraffin wax 7 parts of oil;

[0066] S1. Put the weighed epoxy resin, calcium carbonate powder, phenolic resin, titanium dioxide powder and zinc phosphate powder into the ball mill for fine grinding until the particle diameter is 40um to obtain a mixed powder material;

[0067] S2. Add the mixed powder material, methanol, diethylthiourea and paraffin oil prepared in step S1 into the mixer and stir for 40 minutes. The stirring speed of the mixer is set to 800r / min, and the temperature is set to 70°C to obtain a coa...

Embodiment 3

[0074] The difference with embodiment 2 is the preparation of anti-slip coating, and its specific preparation method is as follows:

[0075] Take the following raw materials and weigh them by weight: 30 parts of epoxy resin, 17 parts of calcium carbonate powder, 50 parts of methanol, 14 parts of phenolic resin, 9 parts of titanium dioxide powder, 9 parts of zinc phosphate powder, 4 parts of diethylthiourea and paraffin wax 5 parts of oil;

[0076] S1. Add the weighed epoxy resin, calcium carbonate powder, phenolic resin, titanium dioxide powder and zinc phosphate powder into the ball mill for fine grinding until the particle diameter is 30um to obtain a mixed powder material;

[0077] S2. Add the mixed powder material, methanol, diethylthiourea and paraffin oil prepared in step S1 into the mixer and stir for 35 minutes. The stirring speed of the mixer is set to 700r / min, and the temperature is set to 60°C to obtain a coarse material ;

[0078] S3, filtering the coarse materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com