Spheroidic ball mill barrel and method for fine pulverizing of permanent magnetic ferrite through spheroidic ball mill barrel

A permanent magnet ferrite and ellipsoid technology, used in grain processing and other directions, can solve the problems of large abnormal growth ratio of magnet crystals, unstable magnet performance, large loss of lining plates, etc., to achieve efficient grinding of raw materials, improve ball milling efficiency, Improve the effect of mechanical energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

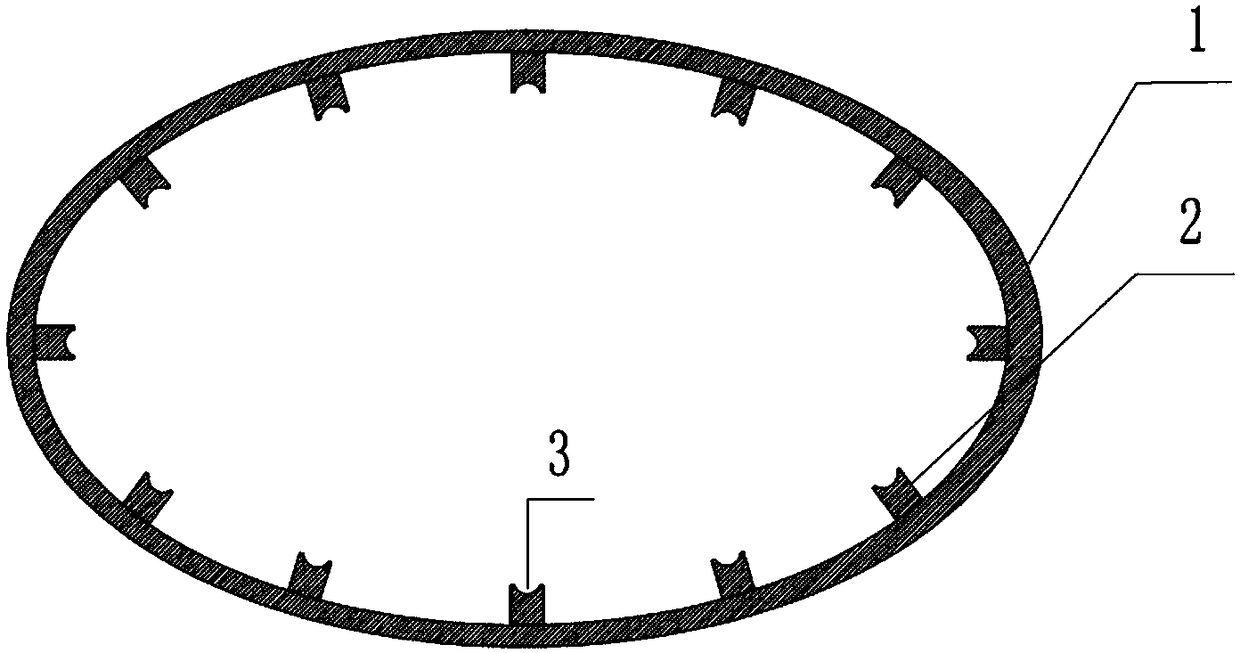

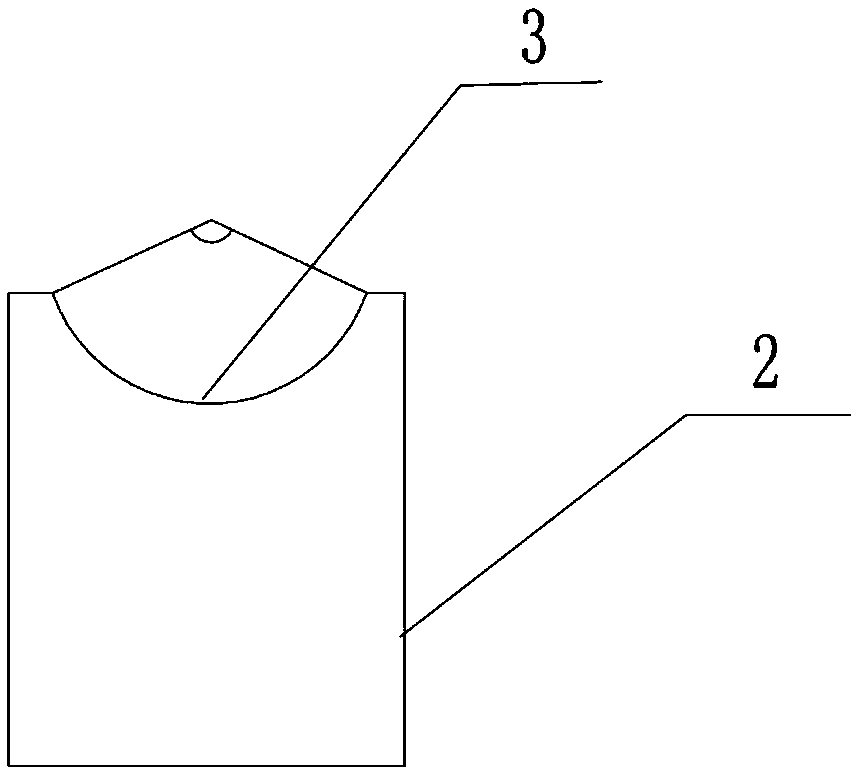

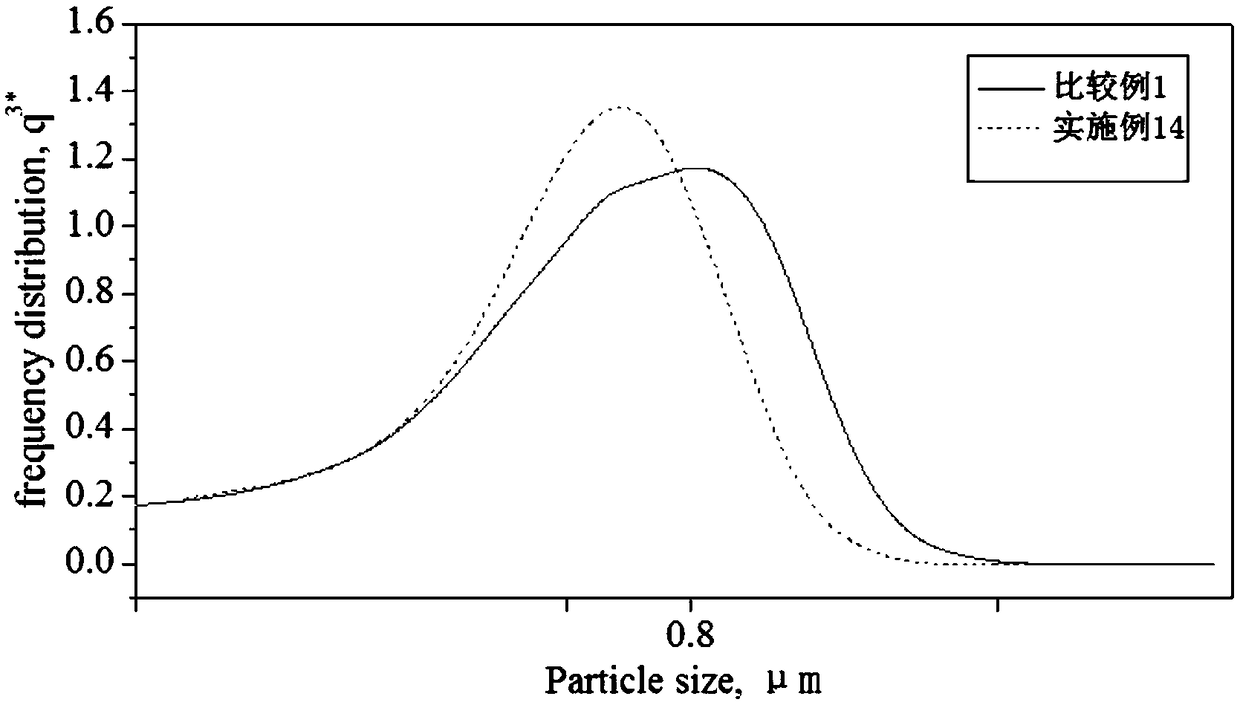

[0032] Such as figure 1 and figure 2 Said: an ellipsoidal ball mill cylinder, the inner wall of the cylinder 1 is provided with a number of reinforcing ribs 2 evenly distributed along the inner wall, and the reinforcing ribs extend from one end of the polar axis of the ellipsoidal cylinder to the other end, The surface of the reinforcing rib close to the inside of the barrel has an arc-shaped depression 3 . The ratio of the polar radius of the cylinder to the two equatorial radii is 1.5:2:1. The rib is in the shape of a cuboid, the ratio of the width of the rib to the longer pole radius is 1:50, and the ratio of the height of the rib to the longer pole radius is 1:40. The number of the reinforcing ribs is 12. The central angle of the concave arc-shaped surface is 80°.

[0033] A method for finely pulverizing permanent magnet ferrite with an ellipsoidal ball mill cylinder, comprising the following steps:

[0034] (1) Add 2.5T of the raw material to be ball milled into the...

Embodiment 2

[0039] The difference between embodiment 2 and embodiment 1 is that in the first stage, the rotating speed of 31r / min is adopted, the ball milling is rotated clockwise for 1 hour and then counterclockwise for 1 hour, and the ball mill is alternately circulated for 4 hours. In the second stage, use a rotating speed of 24r / min, rotate clockwise for 1 hour and then rotate counterclockwise for 1 hour, and alternately circulate the ball mill for 4 hours. In the third stage, use a rotating speed of 20r / min and rotate clockwise for 1 hour. All the other are with embodiment 1.

Embodiment 3

[0041] The difference between embodiment 3 and embodiment 1 is that in the first stage, the rotating speed of 33r / min is adopted, and the ball milling is rotated clockwise for 1 hour and then counterclockwise for 1 hour, and the ball mill is alternately circulated for 5 hours. In the second stage, use a rotating speed of 25r / min, rotate clockwise for 1 hour and then rotate counterclockwise for 1 hour, and alternately circulate the ball mill for 4 hours. In the third stage, use a rotating speed of 20r / min and rotate clockwise for 1 hour. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

| Central angle | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com