Punching and welding integrated device

An integrated, punching and welding technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of large workshop area, high production cost, high energy demand, etc., to achieve fewer clamping times, unchanged functions, and reduced The effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

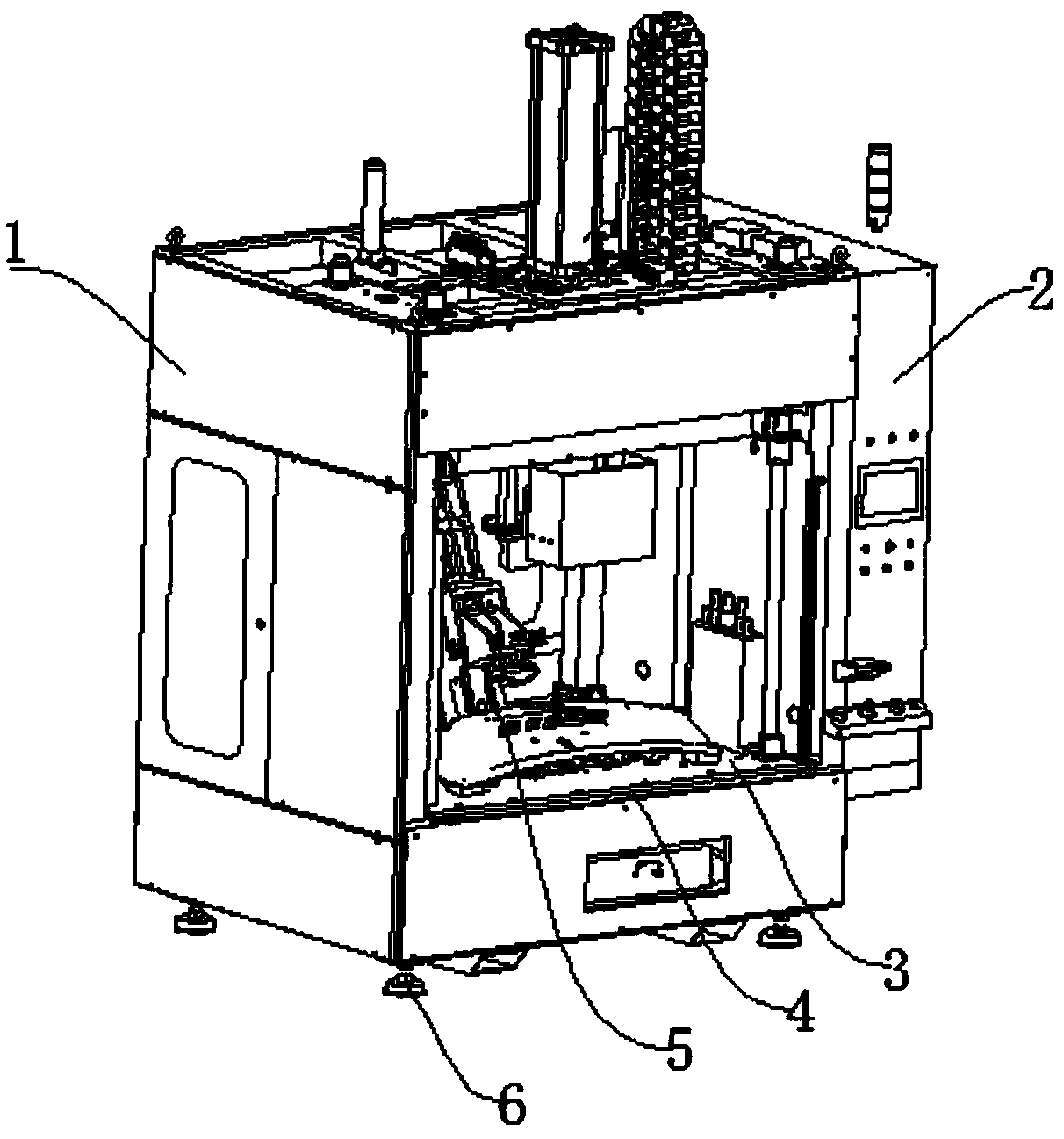

[0018] see figure 1 , the present invention provides a stamping and welding integrated equipment, including a frame 1 and a PLC control box 2, the frame 1 is provided with a membrane system, a pressing mechanism 3, a welding unit 4 and a punching mechanism 5, the The membrane system, the pressing mechanism 3 , the welding unit 4 and the punching mechanism 5 are all electrically connected to the PLC control box 2 .

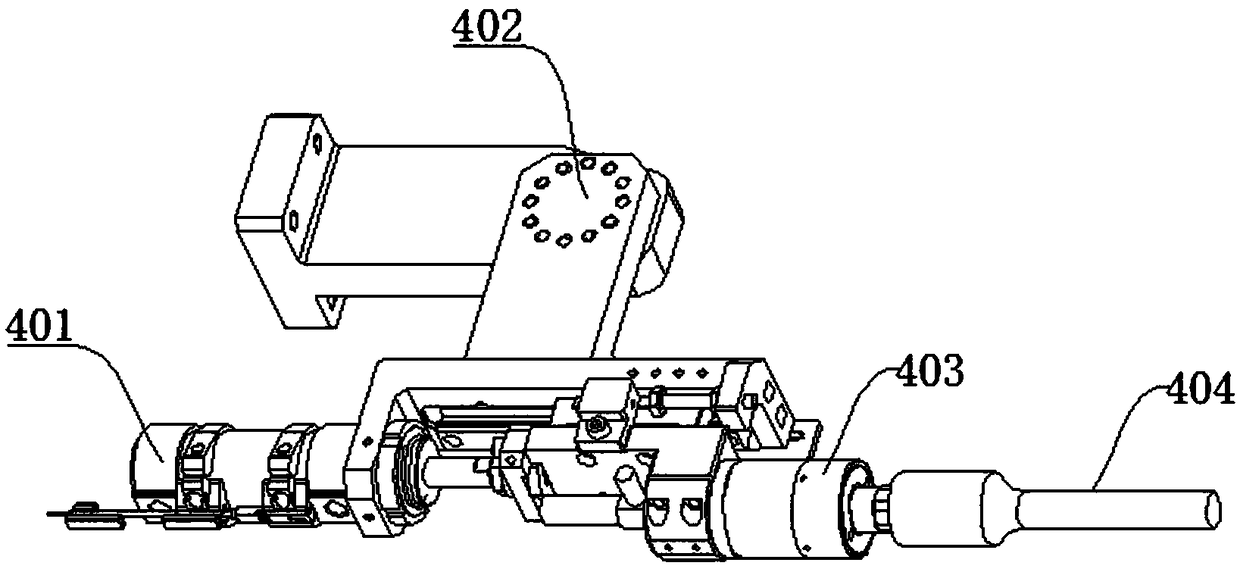

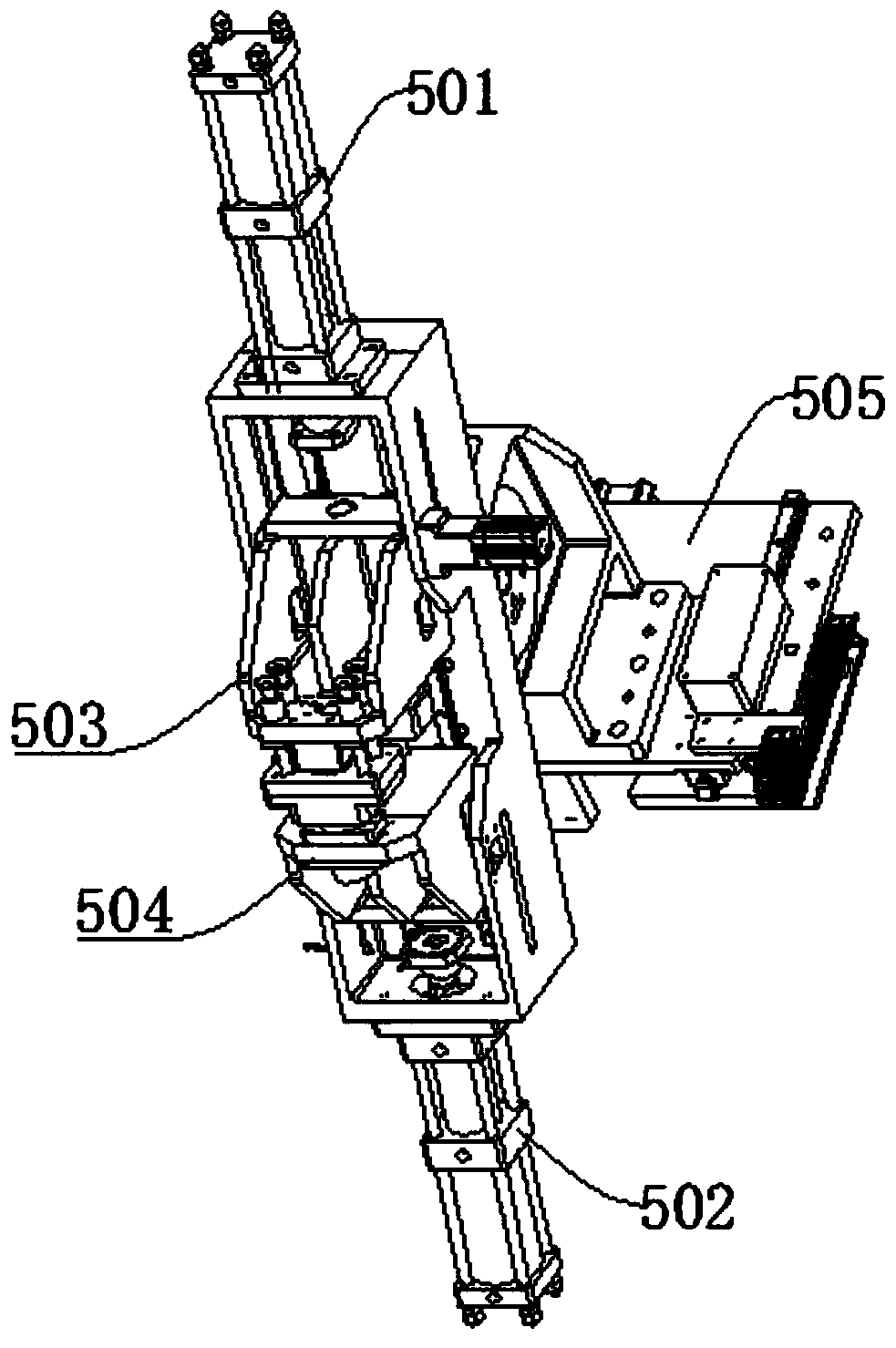

[0019] In the specific implementation process, please refer to Figure 4 , the membrane system and the pressing mechanism 3 include a membrane contour plate 301, on which the membrane contour plate 301 is fixed with a support block 302, a positioning block 303, a compression assembly 304 and a detection switch 305, the membrane contour plate 301 The size of the product meets the ergonomics (easy to pick and place); the support block 302 on the membrane profile plate 301 (some support blocks are coated with PU glue), which protects the product surface while ensurin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com