Prepressing and boxing process for filamentous tobacco materials

A technology of tobacco materials and processing technology, which is applied in the field of material packaging, can solve the problems of increasing transportation costs, reducing the transportation efficiency of tobacco materials, and poor packaging density uniformity, so as to reduce distribution and transportation costs, increase and reduce shredded shred rate, and pack The effect of increased box density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

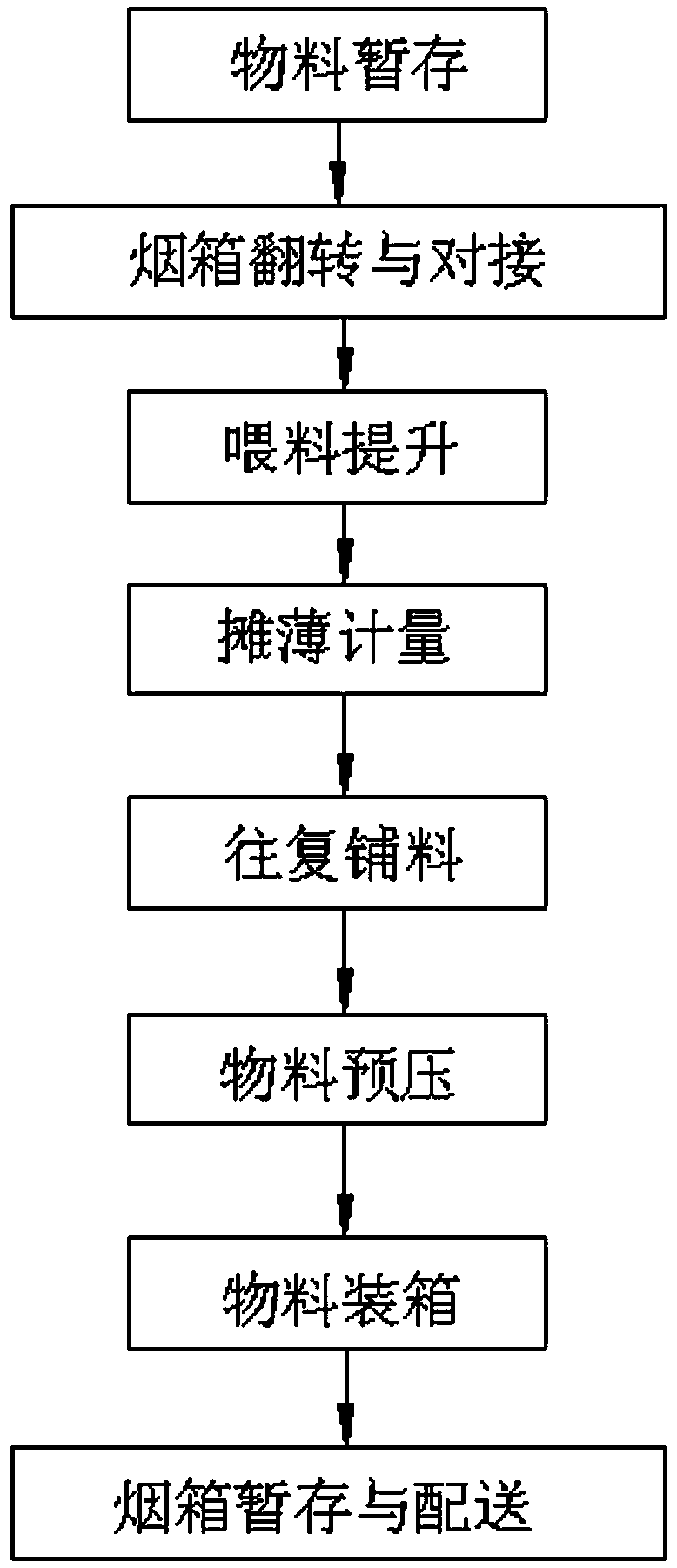

[0034] Such as figure 1 Shown, the present invention comprises the following steps:

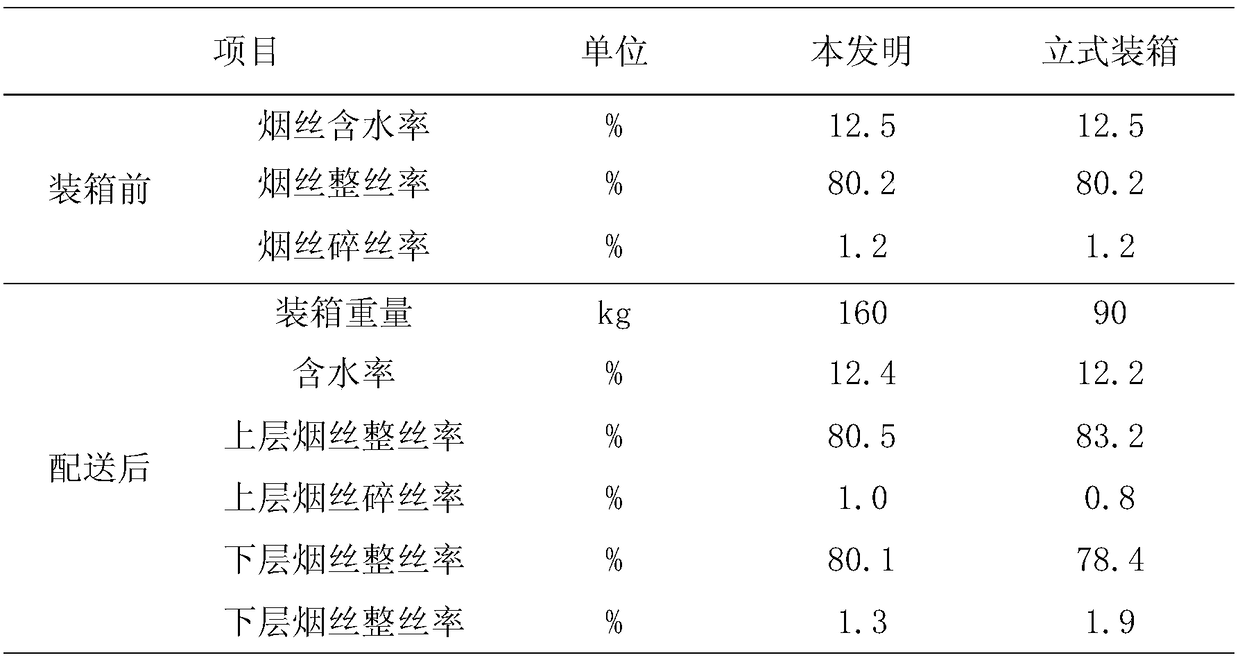

[0035] (1) Temporary storage of materials: the filamentous tobacco materials to be packed are put into the storage cabinet through the upstream material spreading equipment for temporary storage. Uniformity; the moisture content of the tobacco material is 11% to 13%; the temporary storage time of the storage cabinet is ≤72h, the temporary storage environment temperature is 20°C-30°C, and the ambient humidity is 50%-70%. Under this storage environment, the temporary storage time is 0.5h After coming out of the cabinet, the moisture content of cut tobacco was detected to be 12.5%, the whole cut tobacco rate was 80.2%, and the shredded cut rate was 1.2%, which effectively improved the pass rate of cut tobacc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com