A cloth dyeing apparatus for textile printing and dyeing

A technology of textile printing and dyeing and dyeing equipment, which is applied in the field of textile printing and dyeing, can solve the problems of poor dyeing effect and complicated operation, and achieve the effect of improving dyeing effect, simple operation and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

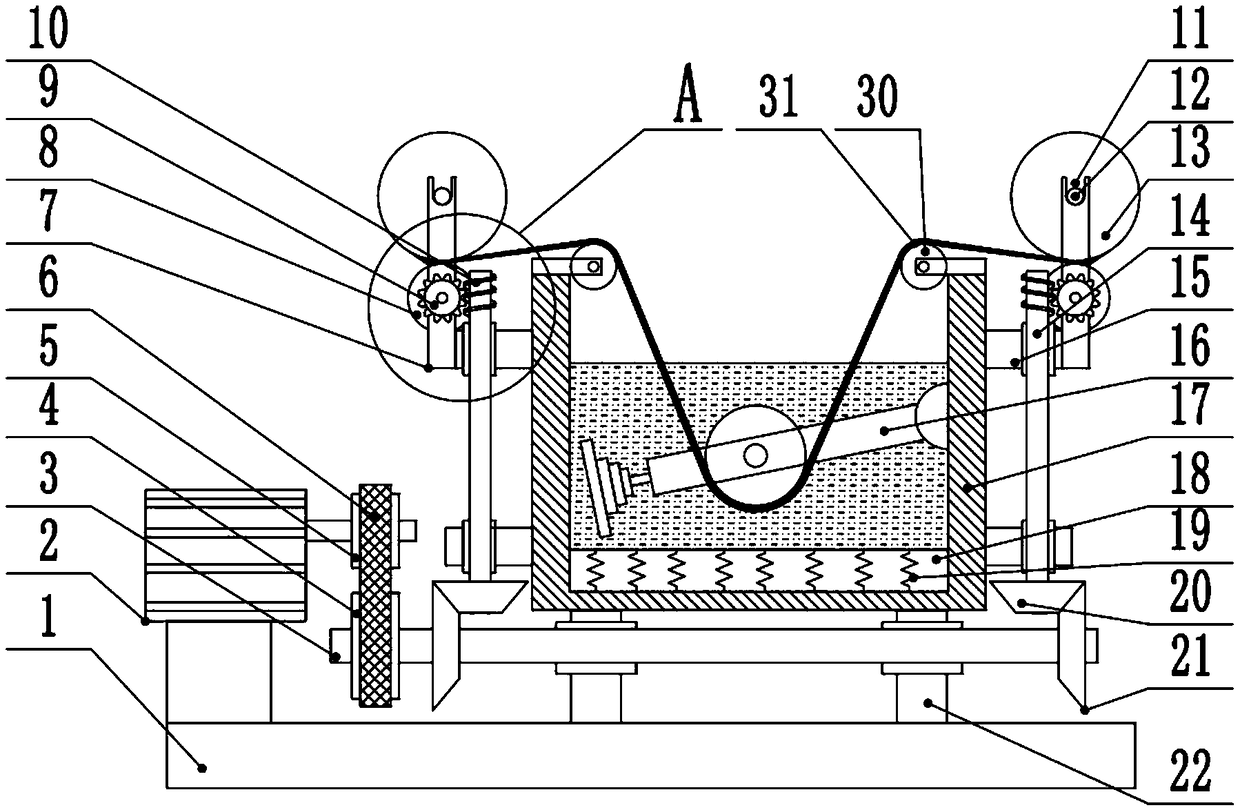

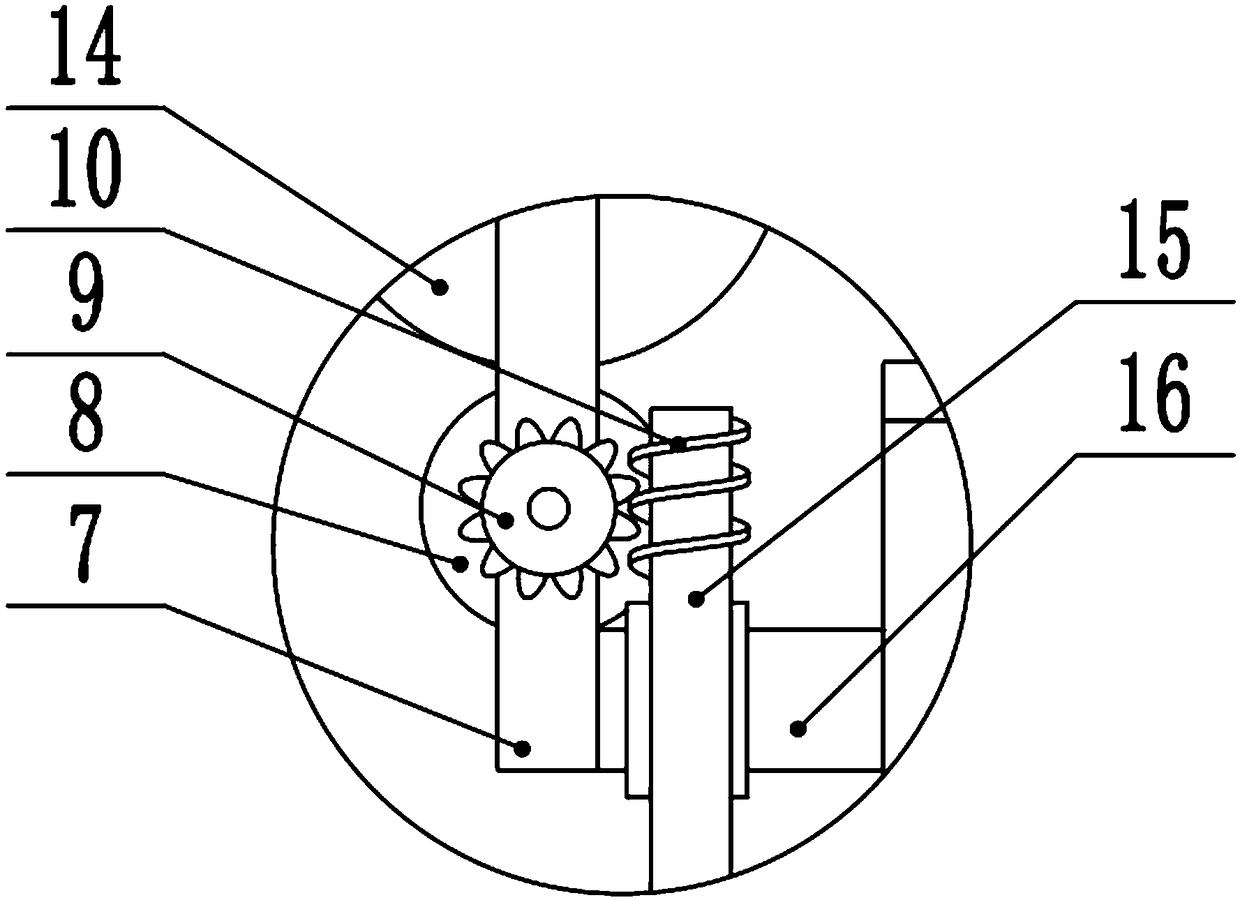

[0024] see figure 1 and 3 , a cloth dyeing device for textile printing and dyeing, comprising a base 1, the middle part of the base 1 is fixedly connected to a column 22, the top of the column 22 is fixedly connected to a dyeing box 17, the left side of the base 1 is fixedly connected to a motor 2, and the output shaft of the motor 2 is fixedly connected The first pulley 5, the first pulley 5 is connected to the second pulley 4 through the belt 6, the second pulley 4 is fixedly connected to the main shaft 3, the column 22 is connected to the main shaft 3 in rotation, and the left and right sides of the main shaft 3 are fixedly connected to the second cone Gear 21, the second bevel gear 21 is meshed with the first bevel gear 20, the first bevel gear 20 is fixedly connected to the worm shaft 14, the worm shaft 14 is provided with a worm 10, the left and right sides of the worm 10 rotate in the opposite direction, the left and right sides of the cone The direction of gear meshin...

Embodiment 2

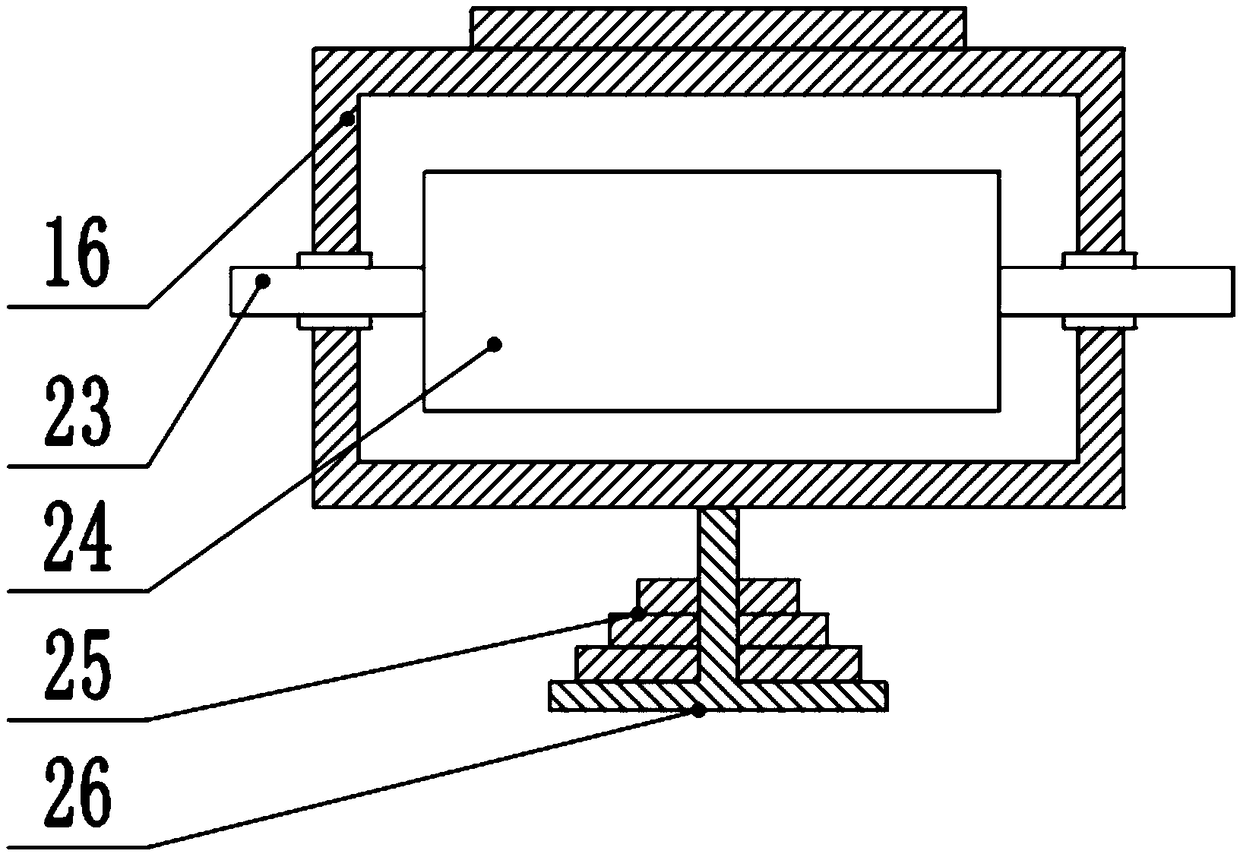

[0027] see Figure 4 , Embodiment 2 is improved on the basis of Embodiment 1. The fixed block 7 is fixedly connected to the contact sensor 27, and the contact sensors 27 on the left and right sides detect whether there is cloth 31 on the driven rollers 13 on the left and right sides, thereby controlling the motor 2; the left side wall of the dyeing box 17 is fixedly connected to a liquid level sensor 28, and as the dyeing continues, the dye solution in the dyeing box 17 will continue to decrease, and when the dye solution is reduced to the warning line, the liquid level sensor 28 The signal is detected and the operator is notified to add the dye solution in time; the right side wall of the dyeing box 17 is fixedly connected with a temperature sensor 29, and the temperature sensor 29 and the heating wire 19 can be used together to keep the temperature of the dye solution in the whole dyeing box 17 constant. Improve the dyeing effect of cloth 31.

[0028] In the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com