Flame-retardant fireproof paper and preparation method thereof

A technology of fireproof paper and flame retardant, which is applied in the preparation of fireproof paper and the field of fireproof paper, which can solve the problems of poor fireproof performance, poor heat insulation function, and short fireproof time of fireproof paper, and achieve low cost, Improve the fire resistance time and evenly distribute the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

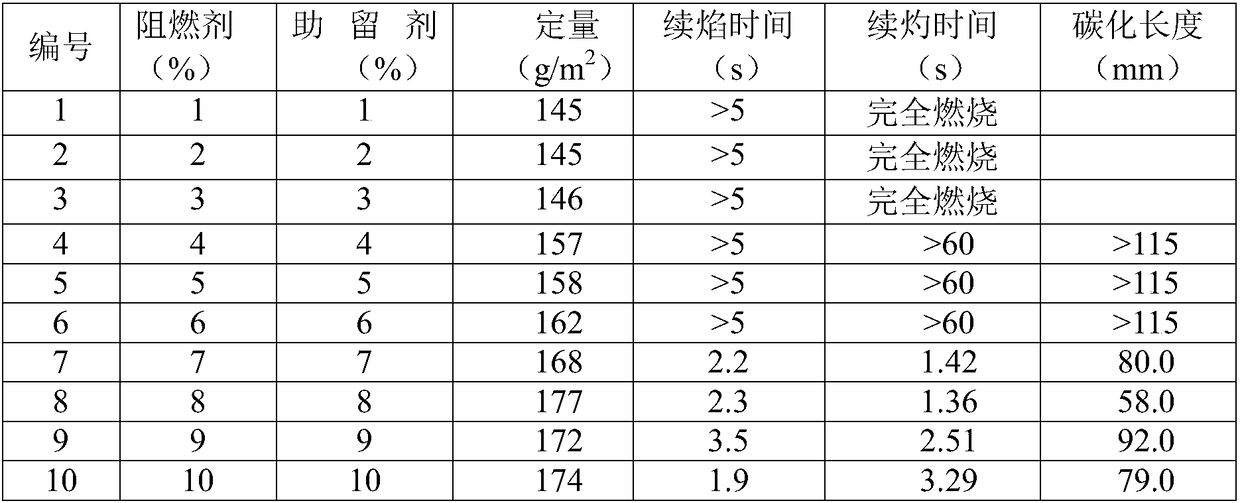

Examples

preparation example Construction

[0023] The preparation method of above-mentioned flame-retardant fireproof paper of the present invention, implement according to the following steps:

[0024] Step 1: Preparation of Flame Retardant

[0025] Mix chlorinated paraffin and methyl silicone oil in a mass ratio of 5:1-5, heat at 80°C-135°C and keep it warm for 30-90 minutes to prepare a flame retardant, which is highly insoluble in water ;

[0026] Step 2: Formulating Retention Aids

[0027] Weigh polyacrylamide, sodium hypochlorite, sodium hydroxide, dimethylamine-epichlorohydrin-dihydroxyethylamine copolymer and sodium sulfite in equal parts by mass; then mix polyacrylamide with sodium hypochlorite and sodium hydroxide, and stir well Finally, add dimethylamine-epichlorohydrin-dihydroxyethylamine copolymer, and add sodium sulfite while stirring at 20°C-25°C until the reaction is terminated; adjust the pH to 4.8-5.0 with hydrochloric acid, and then dilute with water to a solid content of 10%-12% copolymer aqueous...

Embodiment 1

[0038] Step 1: Flame Retardant Preparation

[0039] Mix chlorinated paraffin and methyl silicone oil in a mass ratio of 5:1, and heat at 80°C for 30 minutes to prepare a flame retardant.

[0040] Step 2: Formulating Retention Aids

[0041] Weigh polyacrylamide, sodium hypochlorite, sodium hydroxide, dimethylamine-epichlorohydrin-dihydroxyethylamine copolymer and sodium sulfite in equal parts by mass; then mix polyacrylamide with sodium hypochlorite and sodium hydroxide, and stir well Finally, add dimethylamine-epichlorohydrin-dihydroxyethylamine copolymer, and add sodium sulfite while stirring at 20°C until the reaction is terminated; adjust the pH to 4.8 with hydrochloric acid, and then dilute with water to form a copolymer with a solid content of 10%. aqueous solution;

[0042] Step 3: Prepare the Pulp

[0043] Process the pulp according to the conventional process and keep the constant temperature to obtain the pulp;

[0044] Step 4: Prepare Mixed Material A

[0045] M...

Embodiment 2

[0049] Step 1: Flame Retardant Preparation

[0050] Mix chlorinated paraffin and methyl silicone oil in a mass ratio of 5:2, and heat and keep it at 95°C for 50 minutes to prepare a flame retardant.

[0051] Step 2: Formulating Retention Aids

[0052] Weigh polyacrylamide, sodium hypochlorite, sodium hydroxide, dimethylamine-epichlorohydrin-dihydroxyethylamine copolymer and sodium sulfite in equal parts by mass; then mix polyacrylamide with sodium hypochlorite and sodium hydroxide, and stir well Finally, add dimethylamine-epichlorohydrin-dihydroxyethylamine copolymer, add sodium sulfite while stirring at 25°C until the reaction is terminated; adjust the pH to 4.9 with hydrochloric acid, and then dilute with water to form a copolymer with a solid content of 12%. aqueous solution;

[0053] Step 3: Prepare the Pulp

[0054] Process the pulp according to the conventional process and keep the constant temperature to obtain the pulp;

[0055] Step 4: Prepare Mixed Material A

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com