Super large diameter multiple ultrahigh pressure jet grouting construction method

A construction method and jet grouting technology, applied in infrastructure engineering, construction, sheet pile walls, etc., can solve problems such as poor mud discharge, large mud suction port, clogged clods, etc., to achieve less pollution, ensure quality and The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

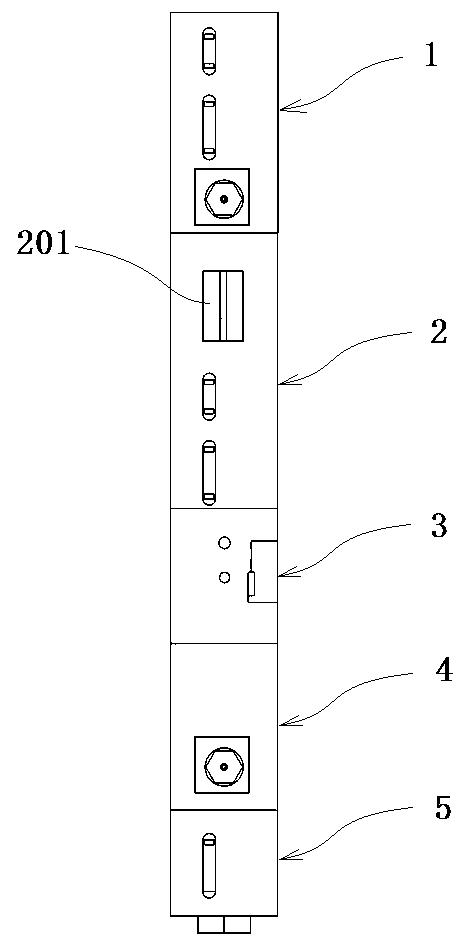

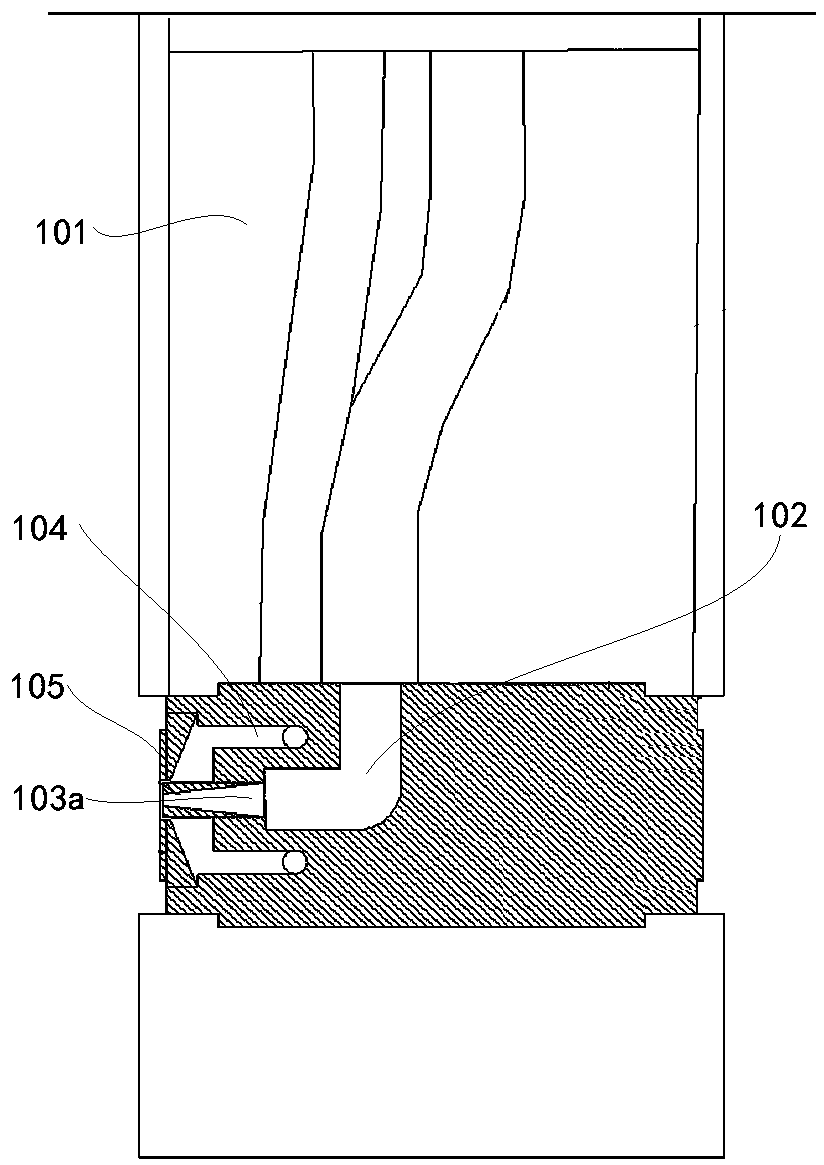

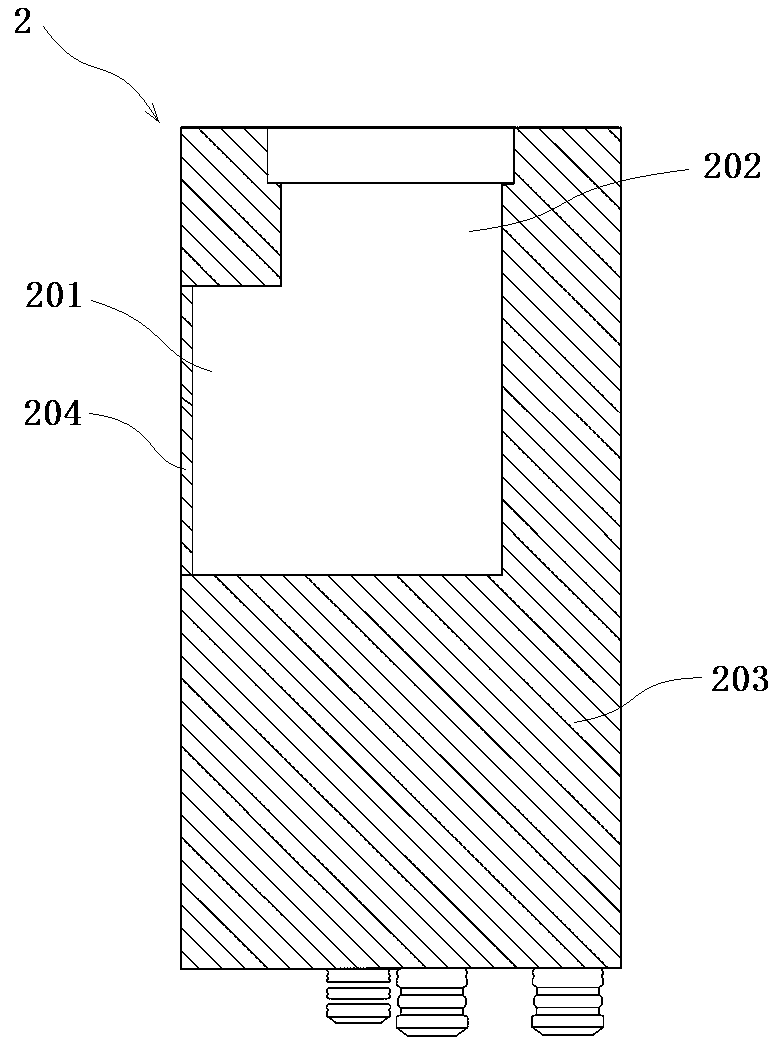

[0030] Example: such as Figure 1-9 As shown, this embodiment specifically relates to a super-large-diameter multiple ultra-high-pressure jet grouting construction method. The construction method mainly uses the upper grouting section 1 set at the lower end of the drilling tool 9 to cut the soil and dilute the mud and use the return The slurry section 2 vacuum pumps the mud, and at the same time, the lower spraying section 4 is used to spray cement slurry outwards to cooperate with the cement slurry sprayed from the upper spraying section 1 to form a jet grouting pile body 11 around the drilling tool. The above grouting method can ensure the quality and efficiency of the grouting, and effectively build a stable jet grouting pile body 11 around and below the drilling tool 9 .

[0031] Such as figure 1 and 7 As shown, before the construction method in this embodiment, the multifunctional head that needs to be installed on the lower end of the drilling tool 9 is prepared in adv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com