Mining combined expanding bit

A technology for reaming drill bits and drill bits, which is applied to drill bits, drilling tools, drill pipes, etc., can solve the problems of low drilling efficiency, low utilization rate, non-replacement, etc., and achieves reasonable overall structure design, easy operation, and avoid long-term use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

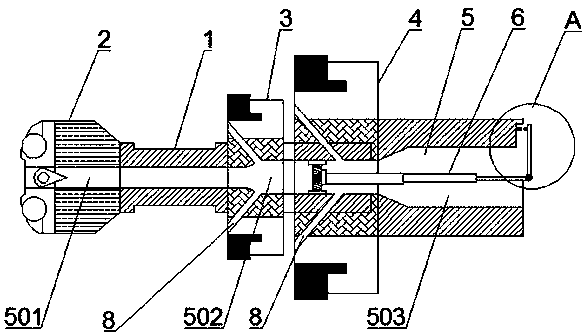

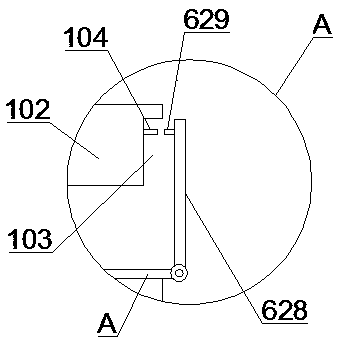

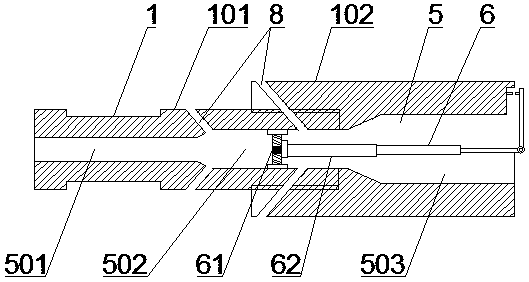

[0024] The mine combined reaming drill bit described in this embodiment has a main body structure comprising a main shaft 1 with an external thread, a first-level drill bit 2, a second-level drill bit 3 and a third-level drill bit 4; the main shaft 1 includes a front main shaft 101 and a front main shaft 101. The rear main shaft 102, the front main shaft 101 and the rear main shaft 102 are coaxially arranged, the diameter of the front main shaft 101 is smaller than the diameter of the rear main shaft 102, and the right end of the front main shaft 101 is threadedly connected with the left end of the rear main shaft 102; There is an internal thread used in conjunction with the external thread, which is threaded with the left end of the front main shaft 101; connection; the three-stage drill bit 4 is provided with an internal thread used in conjunction with the external thread, and is threadedly connected with the left end of the rear main shaft 102; the main shaft 1 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com