LNG gas supply system on deck transport ship

A technology of gas supply system and transport ship, which is applied in the field of ships, can solve the problems of low safety factor and low degree of automation, and achieve the effects of saving fuel, ensuring continuous supply and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

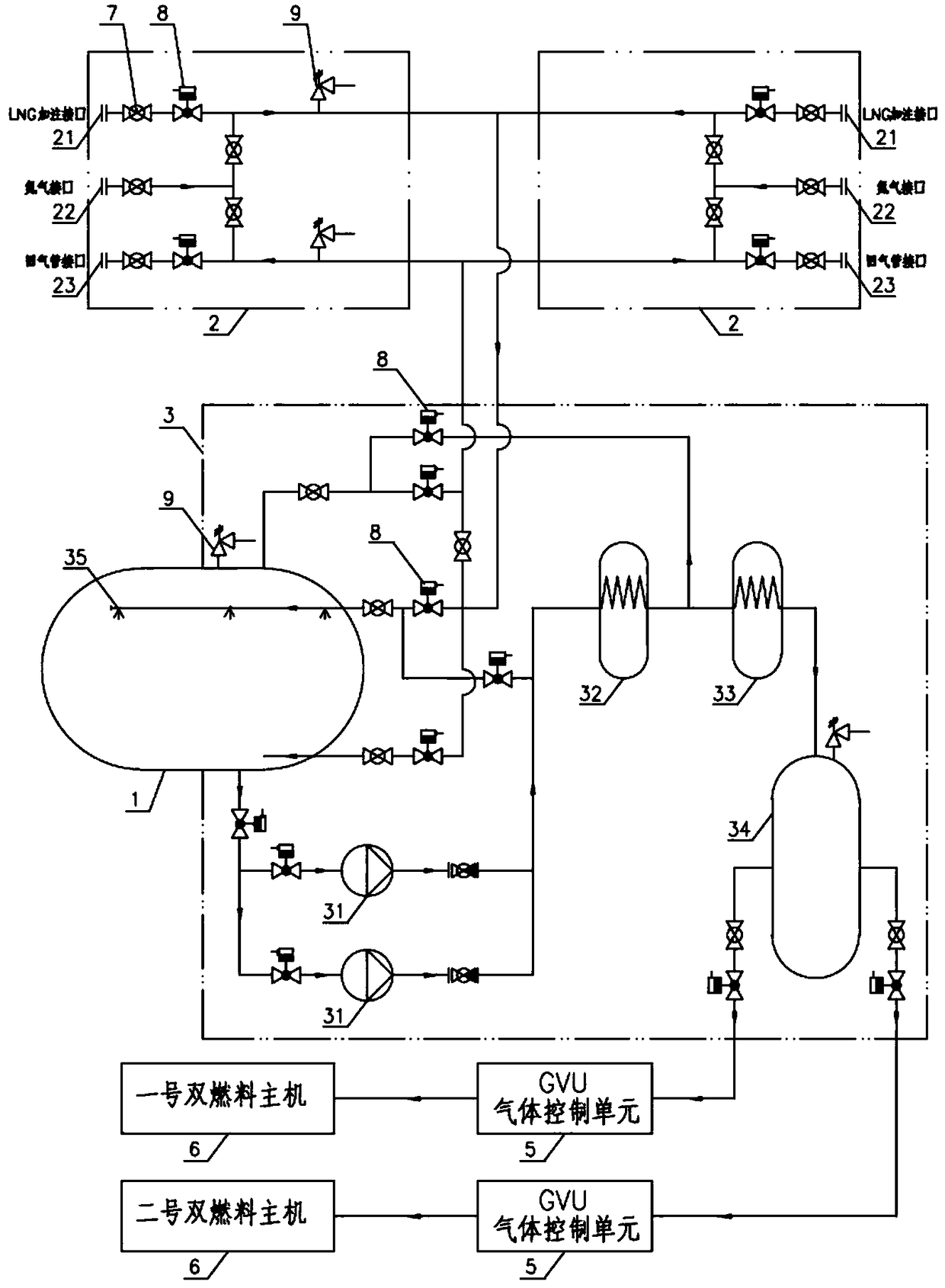

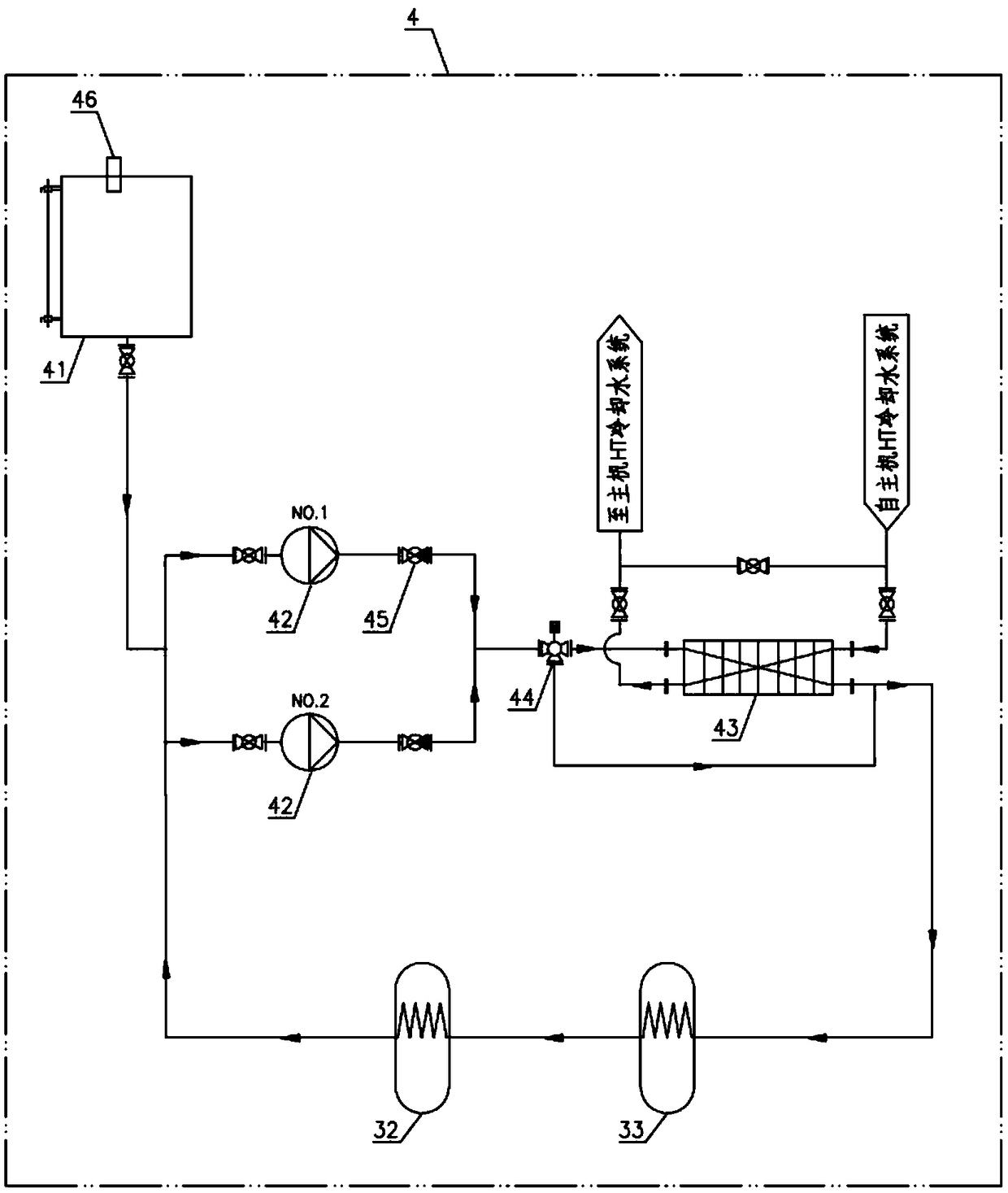

[0040] like figure 1 , figure 2 As shown, an LNG gas supply system on a deck transport ship includes at least one or two LNG fuel tanks 1, two sets of fuel filling and containment systems 2, and an LNG fuel pressurized gasification / heating system 3, gas supply Auxiliary system 4, safety monitoring / emergency shut-off system; among them, the fuel filling and containment system 2 forms a connection circuit with the LNG fuel tank 1, and the LNG fuel pressurized gasification / heating system 3 vaporizes and heats the LNG fuel before transporting it to the dual-fuel main engine 11; the gas supply auxiliary system 4 provides a heating heat source for the LNG fuel pressurized gasification / heating system 3; the safety and monitoring / emergency cut-off system is used to monitor the liquid level, pressure, temperature and gas supply of the LNG fuel tank 9 Systematic LNG leakage monitoring, fire detection system and emergency shutdown system.

[0041] In addition, the fuel filling and con...

Embodiment 2

[0049] like figure 1 , figure 2 As shown, an LNG gas supply system on a deck transport ship includes at least one or two LNG fuel tanks 1, two sets of fuel filling and containment systems 2, and an LNG fuel pressurized gasification / heating system 3, gas supply Auxiliary system 4, safety monitoring / emergency shut-off system; among them, the fuel filling and containment system 2 forms a connection circuit with the LNG fuel tank 1, and the LNG fuel pressurized gasification / heating system 3 vaporizes and heats the LNG fuel before transporting it to the dual-fuel main engine 11; the gas supply auxiliary system 4 provides a heating heat source for the LNG fuel pressurized gasification / heating system 3; the safety and monitoring / emergency cut-off system is used to monitor the liquid level, pressure, temperature and gas supply of the LNG fuel tank 1 Systematic LNG leakage monitoring system, fire detection system and emergency shutdown system.

[0050] In this embodiment, the LNG fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com