Lamp, vehicle with lamp and vehicular lamp demisting method

A lamp body and lamp technology, which is applied to road vehicles, vehicle parts, motor vehicles, etc., can solve the problems of space occupation in the lamp, difficulty in air circulation in the lamp, dehumidification speed and effect need to be improved, and achieve an effective dehumidification method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

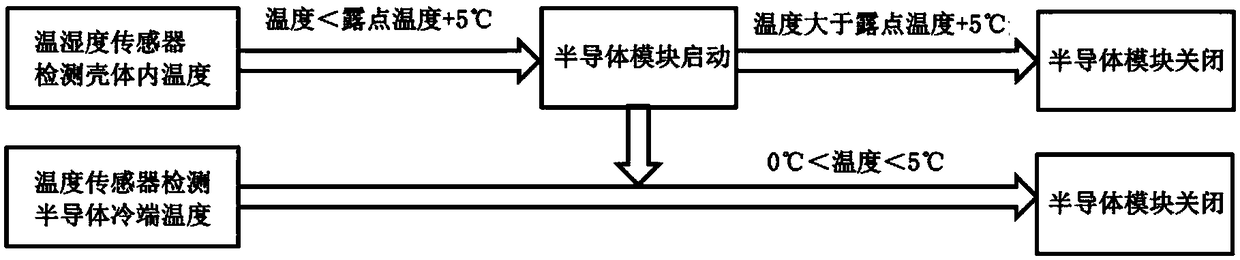

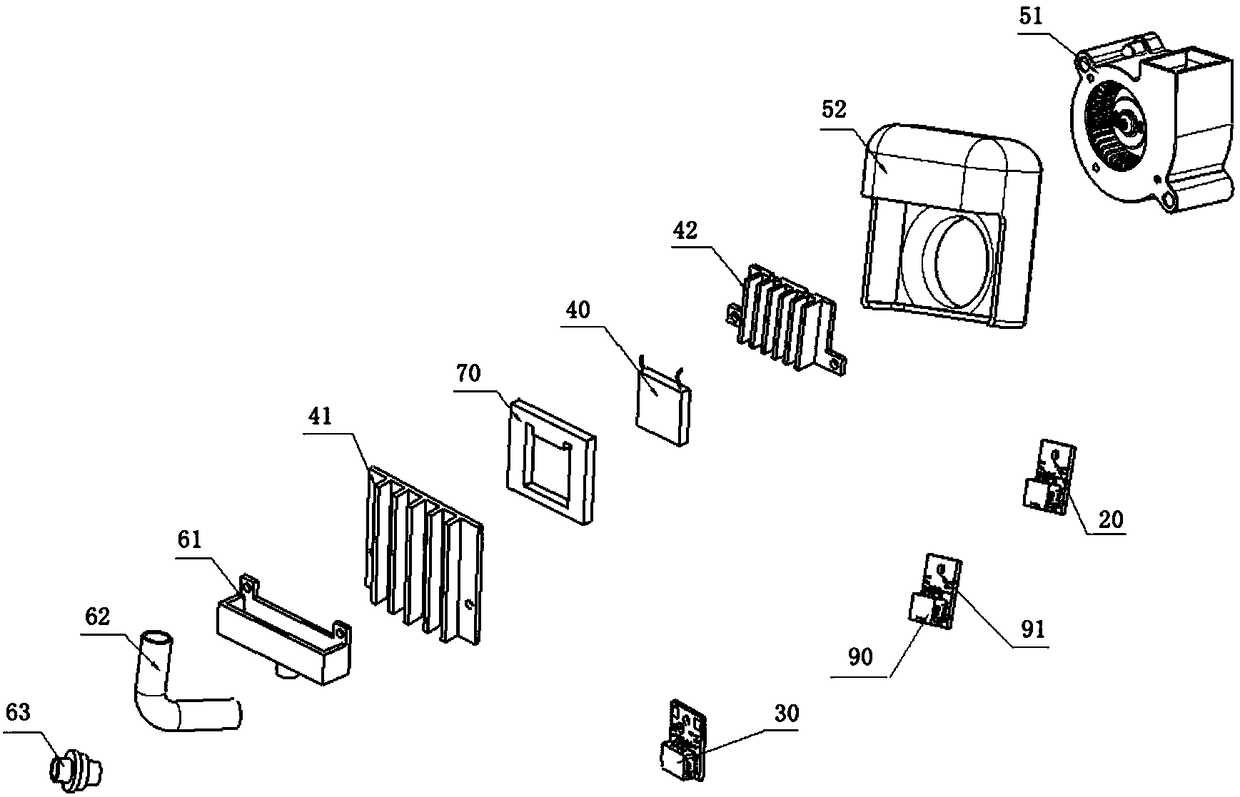

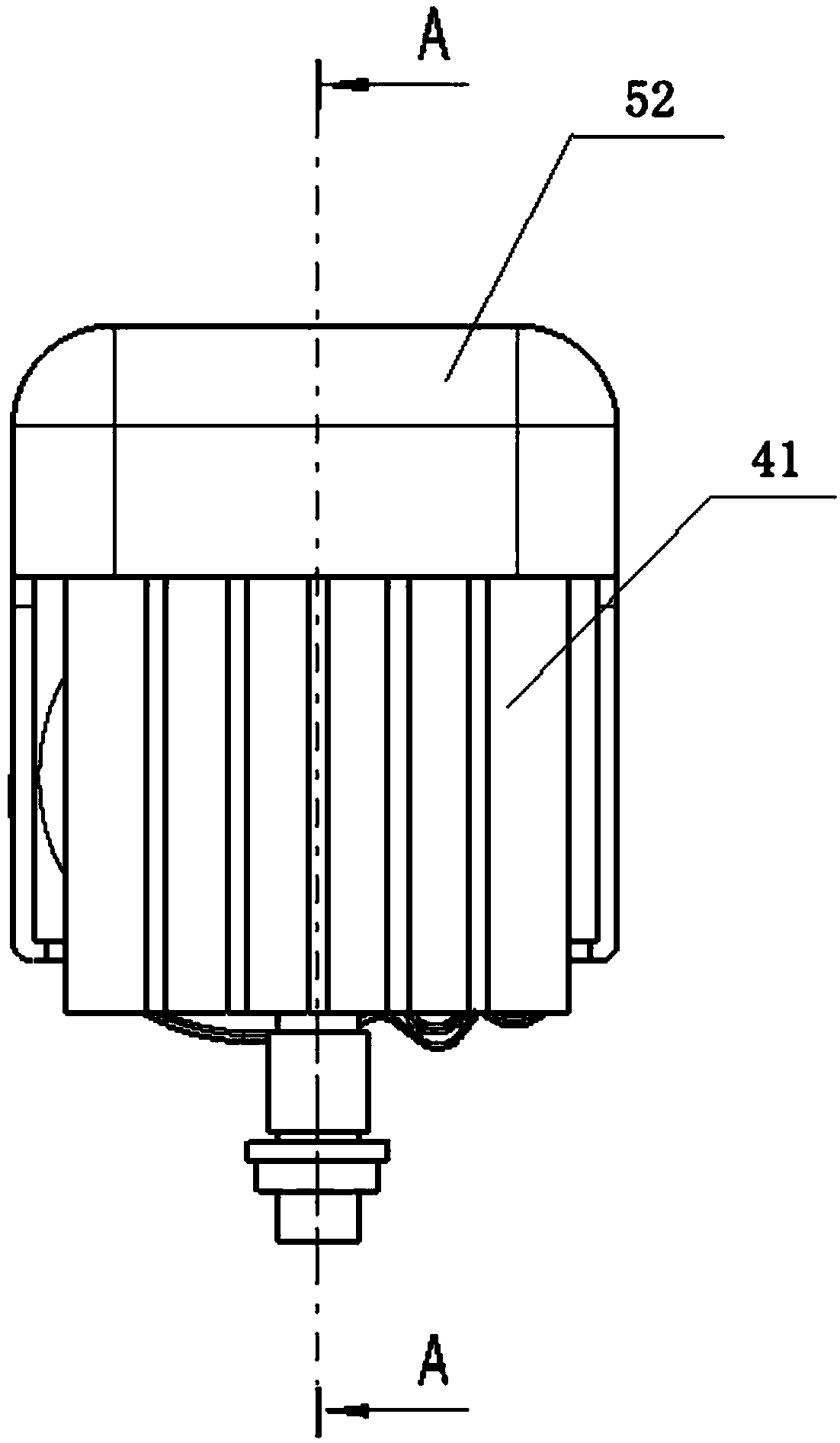

[0072] Refer to Figure 2-4 In this embodiment, the semiconductor condensing module 40 is arranged in the ventilation duct 52. Specifically, the semiconductor condensing module 40 is fixed with respect to the air outlet direction of the fan 51, the cold end and the cold end heat sink 42 in the semiconductor condensing module 40 face the fan 51, and the hot end and the hot end heat sink 41 face away from the fan 51. Such as Figure 4 As shown, the dotted line points to the air flow direction. After the fan 51 is started, the air in the housing 10 is drawn into the fan 51 through the air inlet by the fan 51 for cooling. The air from the fan 51 is first sent to the semiconductor condensing module 40 through the ventilation duct 52 until the cold end and the cold end dissipate heat. The heat of the cold end fin 42 is taken away by the blowing air. The cold end condenses the water vapor in the wind and forms water droplets out of the shell 10; the remaining air will become dry and l...

Embodiment 2

[0074] Refer to Figure 5-7 The semiconductor condensing module 40 is also arranged in the ventilation duct 52, the hot end and the hot end heat sink 41 are facing the fan 51, and the cold end and the cold end heat sink 42 are facing away from the fan 51. Such as Figure 7 As shown, the dotted line points to the air flow direction. After the fan 51 is started, the air in the housing 10 cooled by the fan 51 first passes through the hot-end heat sink 41, and then cools the hot-end heat sink 41, and then blows the air to the cold end and the cold-end heat sink 42, the cold end and The cold end heat sink 42 condenses the water vapor and discharges water droplets out of the lamp body. As the air passes through the cold end, the temperature of the air will decrease and become dry, making it difficult to generate fog in the lamp.

[0075] The difference between the first embodiment and the second embodiment above is that the order of heat dissipation and dehumidification is reversed. ...

Embodiment 3

[0077] Refer to Figure 8-10 , An opening is provided on the housing 10 of the lamp body, and the hot-end heat sink 41 has an extension part in addition to a plurality of heat dissipation fins. The extension part extends through the opening to the outside of the housing 10, the hot-end heat sink 41 Part 41 is arranged inside the housing 10, and part is arranged outside the housing 10 to dissipate heat through conduction. The cold end and cold end heat sink 42 are attached to the hot end heat sink 41 arranged in the housing 10 to dehumidify the air in the housing 10. The nature of the hot-end heat sink 41 reduces the temperature by itself, which can save costs. It can be understood that, in order to prevent water or dust from infiltrating into the gap between the extension and the opening, a sealing ring 80 may be provided between the extension and the opening to prevent water and dust.

[0078] In the above three embodiments, the drainage module can be configured to include a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com