Adjustable constant current temperature measuring system and method

A technology of temperature measurement module and constant current source module, which is applied in thermometers, measuring devices, heat measurement, etc., can solve the problems of not being able to measure relevant data quickly, reliably and accurately, low detection efficiency, low detection accuracy, etc., and achieve rich Human-machine interface, improved measurement efficiency, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

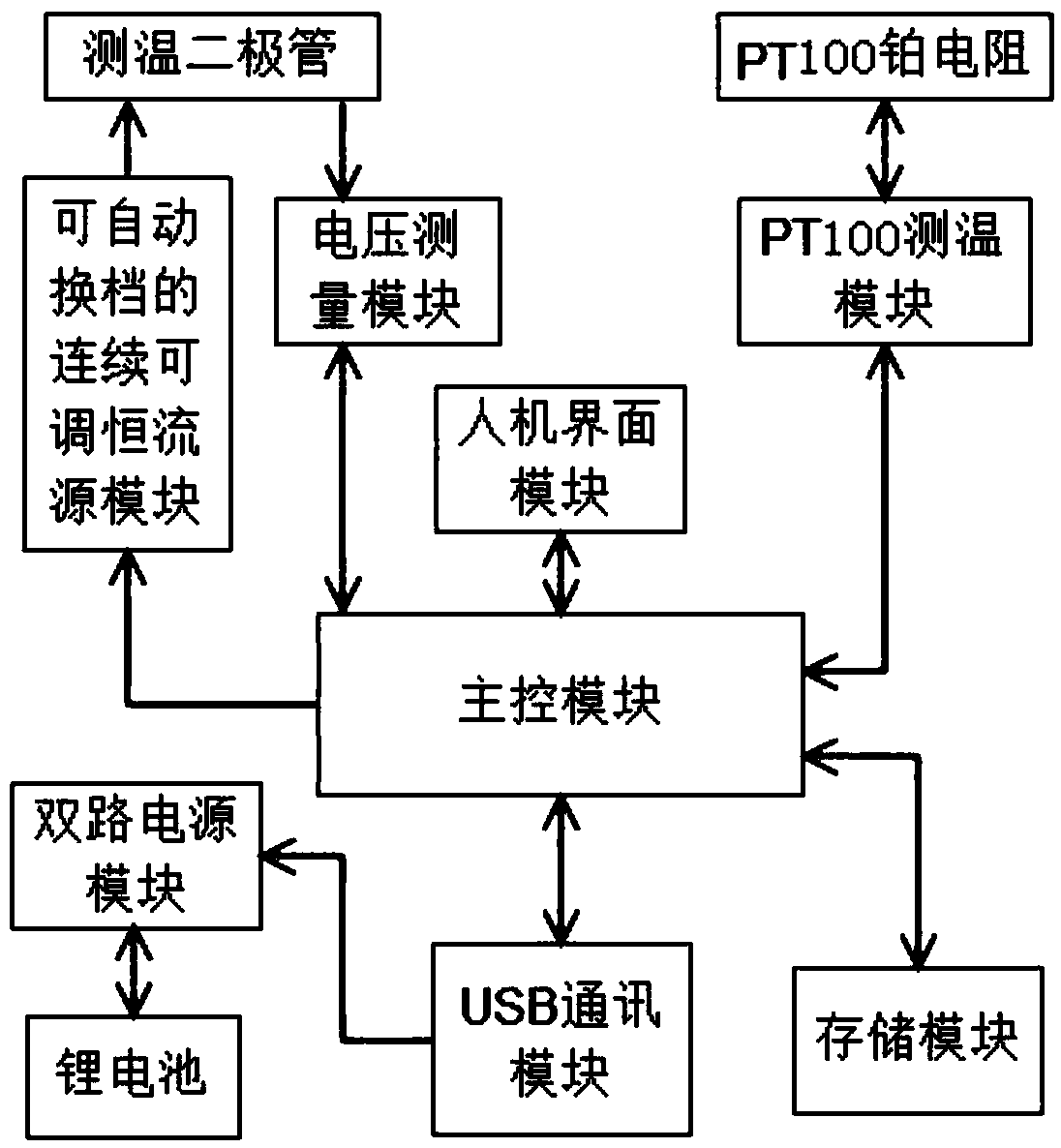

[0048] Such as figure 1 and figure 2 As shown, an adjustable constant current temperature measurement system of the present invention is used for temperature measurement of temperature measurement diodes and / or PT100 platinum thermal resistance sensors, which includes:

[0049] main control module;

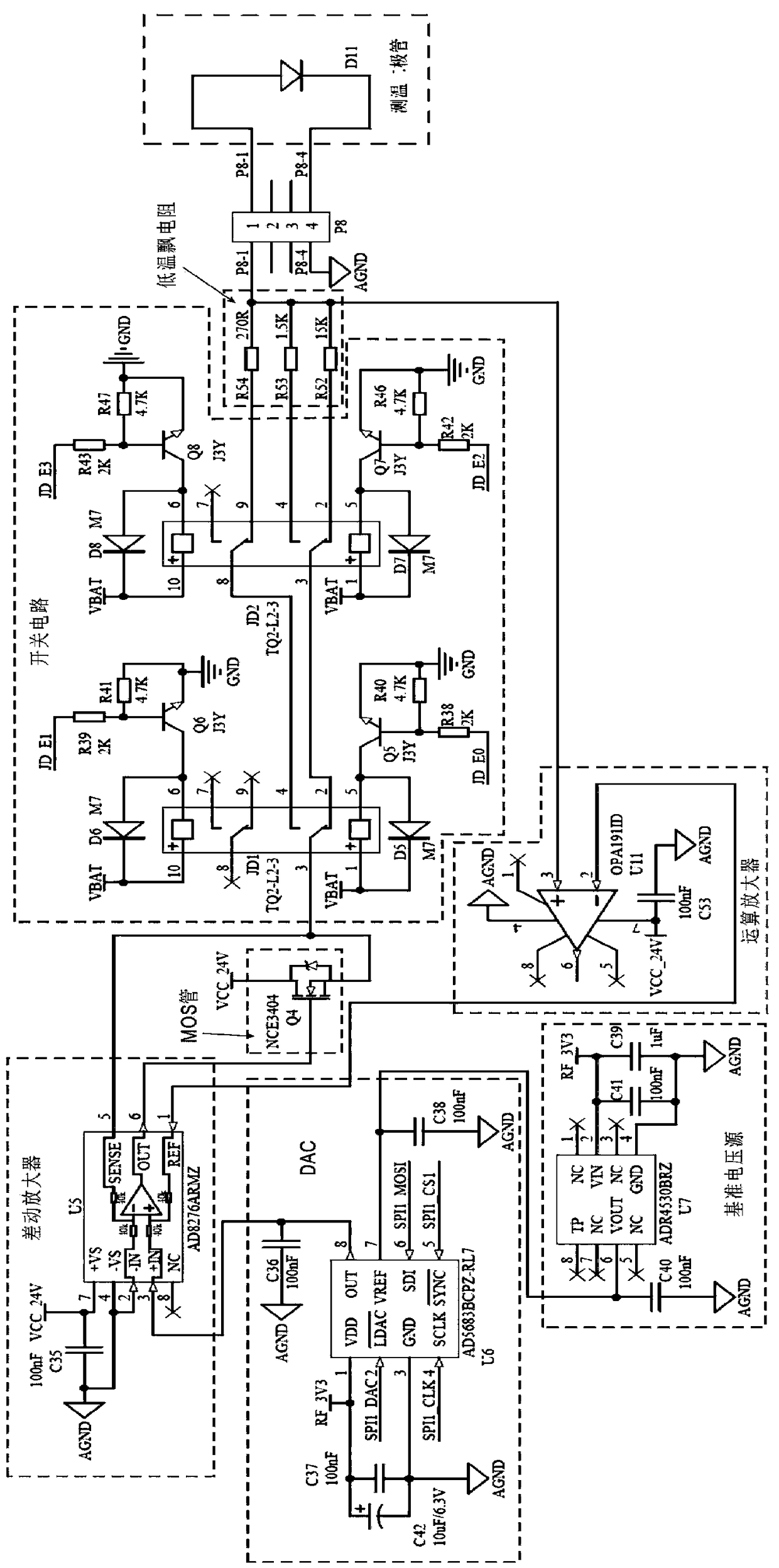

[0050] A continuously adjustable constant current source module that is used to provide a constant bias current value for the temperature measuring diode so that the two ends of the temperature measuring diode generate a corresponding voltage as the temperature changes;

[0051] A voltage measurement module for collecting the voltage signal at both ends of the temperature measuring diode and converting it into a digital signal;

[0052] The PT100 platinum thermal resistance sensor temperature measurement module is used to output a fixed bias current value to the PT100 platinum thermal resistance sensor, and then collect the corresponding voltage signal generated by the two ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com