Equipment for testing permanent magnetic rotor magnetic steel, and testing method of rotor magnetic steel

A permanent magnet rotor and magnet technology, which is applied in the test of rotor magnets and the field of equipment for testing permanent magnet rotor magnets, can solve the problems of not testing the performance of magnet components, and achieve simple and easy working principles and stable and reliable data , high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

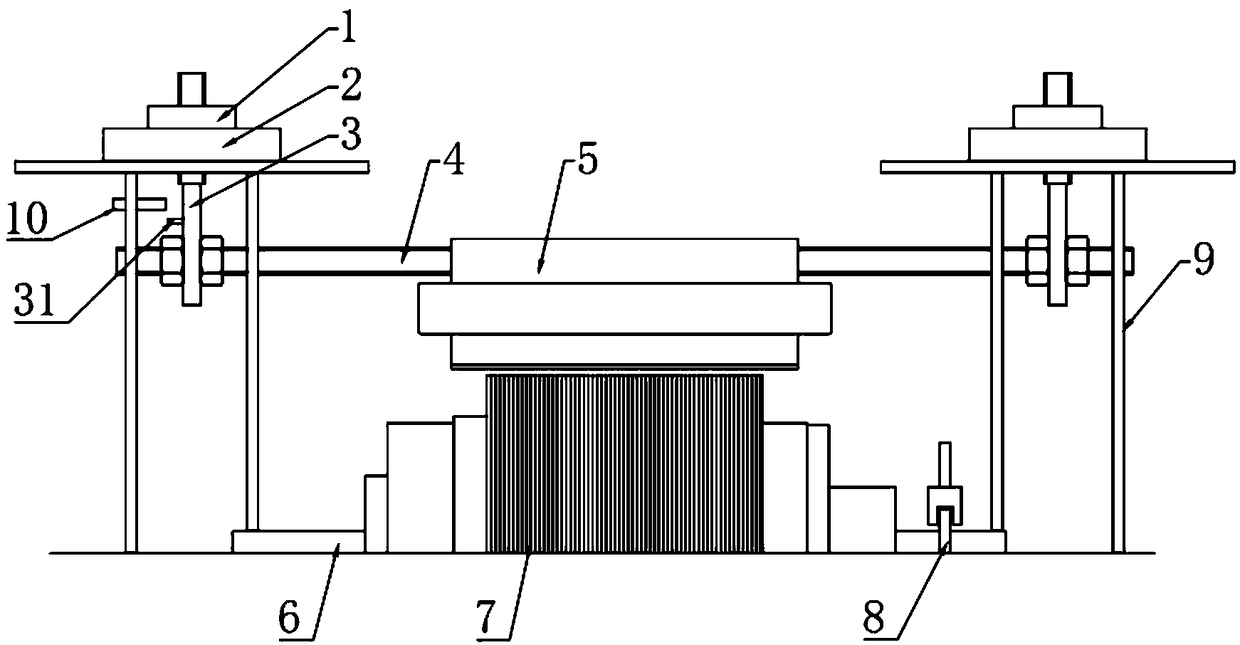

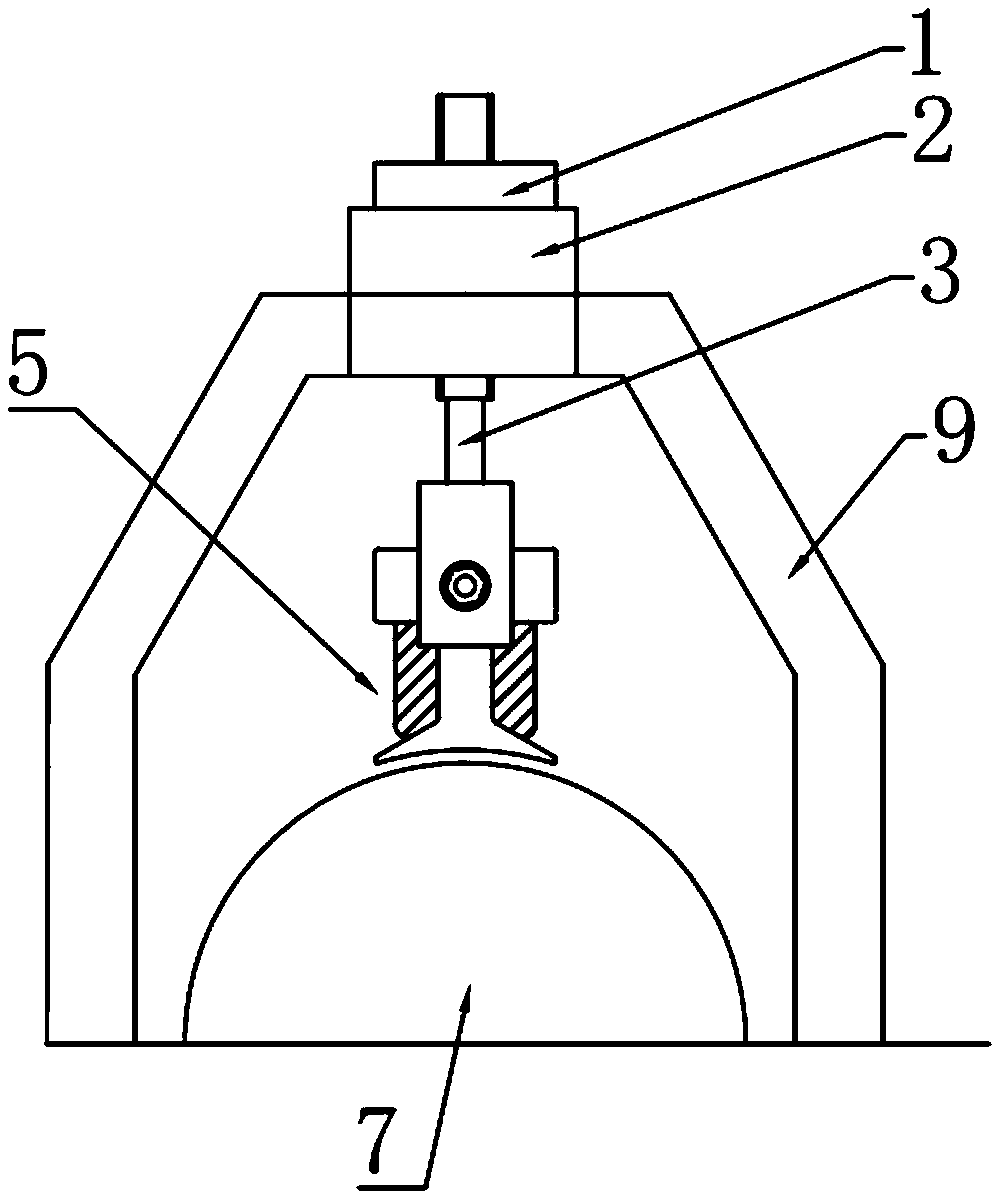

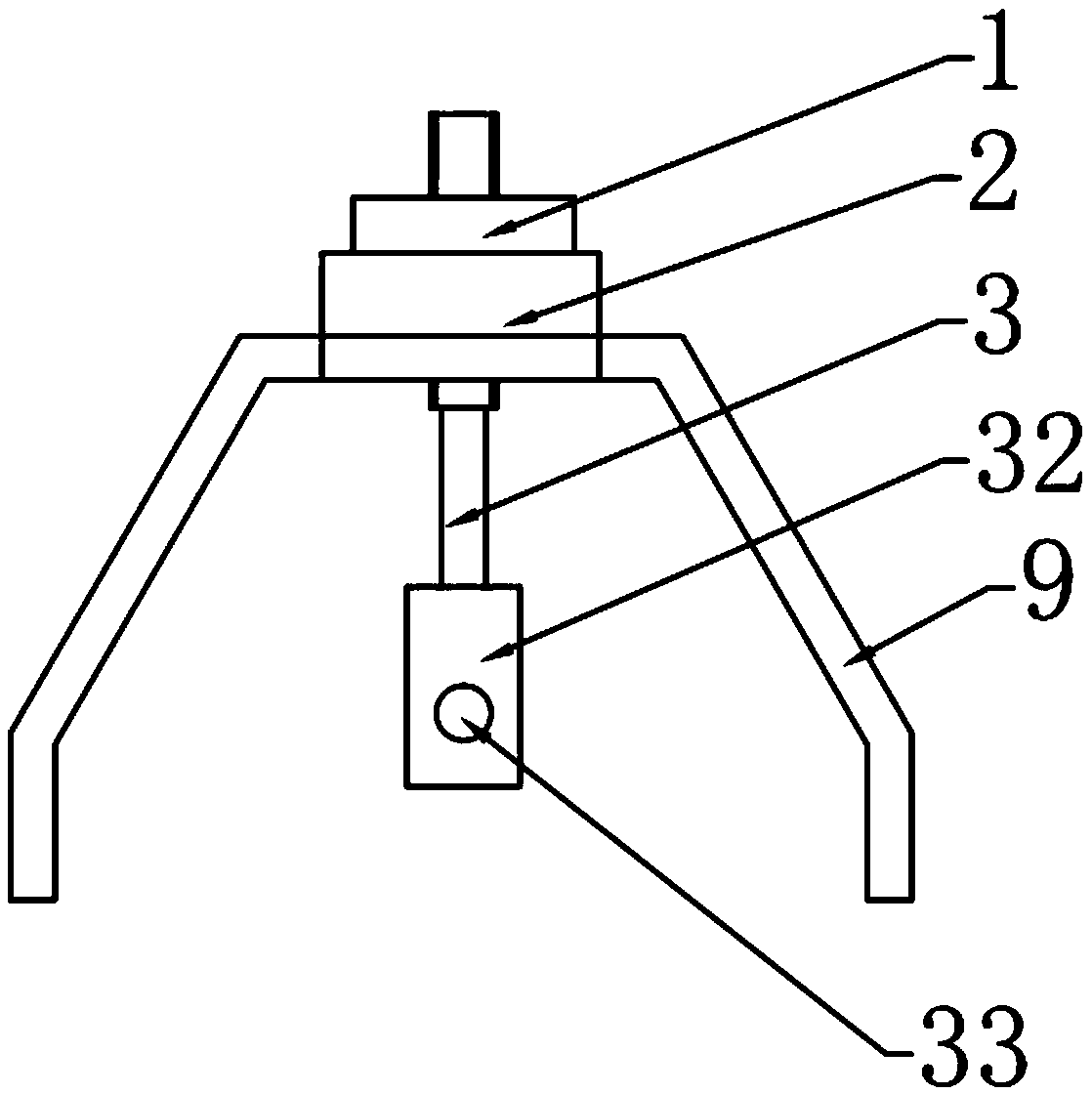

[0041] Such as figure 1 , 2 The equipment for testing permanent magnet rotor magnetic steel shown includes a driving motor 1, a dial 2, a first screw 3, a second screw 4, a winding iron core 5, a dynamic balancing tool 6, a rotor 7, and a photoelectric sensor 8 , a support frame 9 and a proximity switch 10, the support frame 9 is erected on the left and right ends of the dynamic balancing tool 6, the rotor 7 is installed on the dynamic balancing tool 6, the driving motor 1 is connected to the dial 2, and the The first screw rod 3 is connected with the dial 2, the dial 2 is set on the support frame 9, the first screw rod 3 is covered with a slider 32, and the second screw rod 4 is set on the slider 32 , the upper end of the winding iron core 5 is sleeved on the second screw mandrel 4, and the winding iron core 5 is arranged above the rotor 7, and the right end of the dynamic balancing tool 6 is provided with a photoelectric sensor 8, so The proximity switch 10 is disposed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com