Automatic marking device of large-capacity grating array optical cable and marking method of automatic marking device

A grating array and large-capacity technology, which is applied in the direction of light guides, optics, and optical components, can solve the problems of high marking accuracy and the inability of large-capacity grating array optical cables to accurately locate the position of the grating, and achieve high marking accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

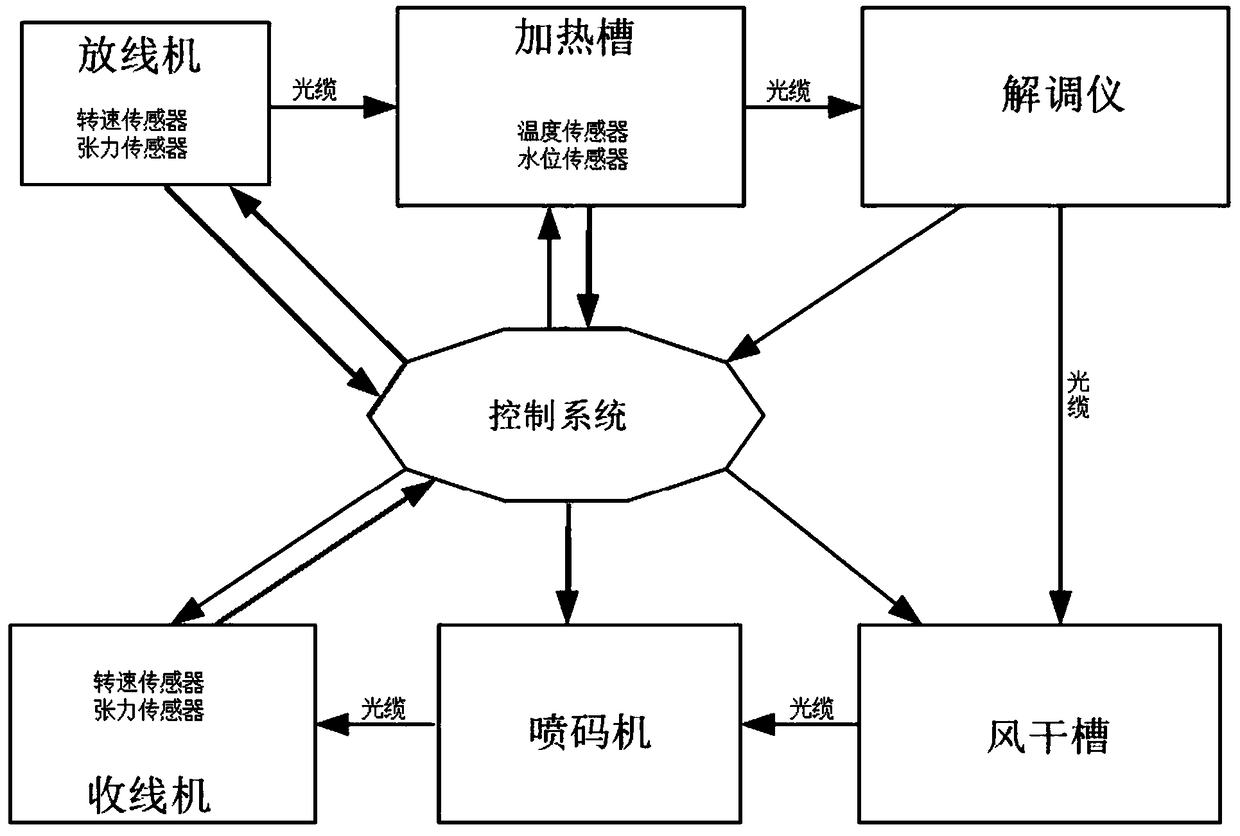

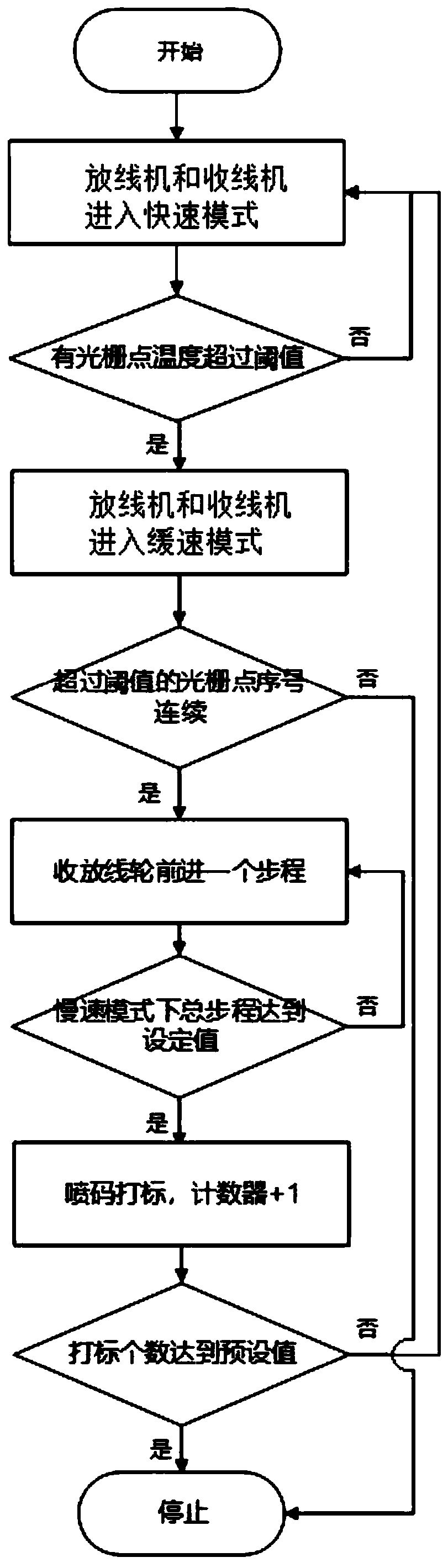

[0018] Such as figure 2 As shown, an automatic marking device for a large-capacity grating array optical cable includes a control system (in this embodiment, the control system is programmed using the labview platform, which is flexible in programming and has a high degree of visualization) and sequentially arranged along the route of the optical cable. A pay-off machine for laying out the optical cable, a heating tank for heating the optical cable through water, a demodulator for detecting the temperature of each grating point in the optical cable and recording the serial number of the grating point (in this embodiment, the demodulator The regulator adopts FBGDS-3000 from Wuhan Fengli Optoelectronics Technology Co., Ltd., a single channel can load 50,000 gratings, the temperature measurement accuracy reaches ±1°C, the spatial resolution is 1 meter, and the demodulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com