Adhering isolation layer prevention spraying equipment special for silicon rubber wires and cables

A technology for wire and cable and spraying equipment, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as uneven spraying, slow spraying speed, poor effect, etc., and achieve uniform spraying, low air consumption, and spraying feel. Oil even effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

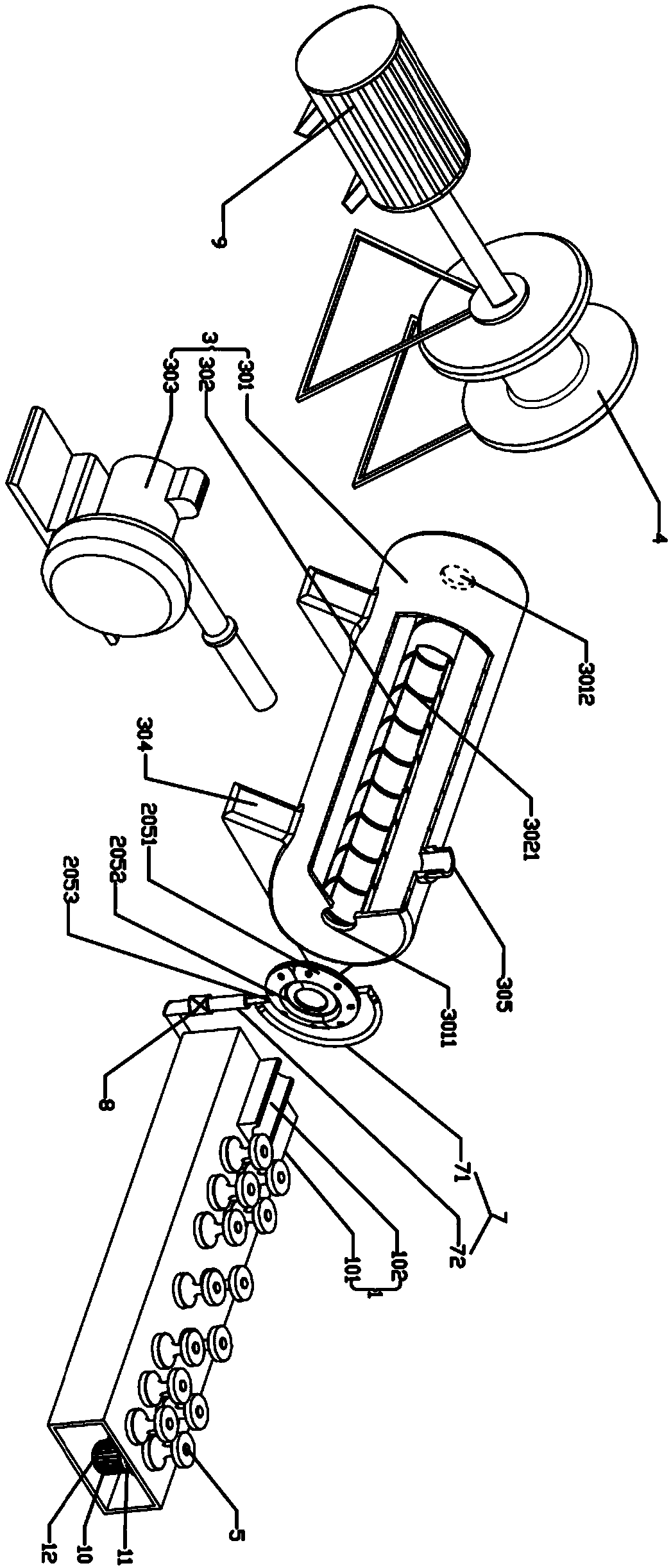

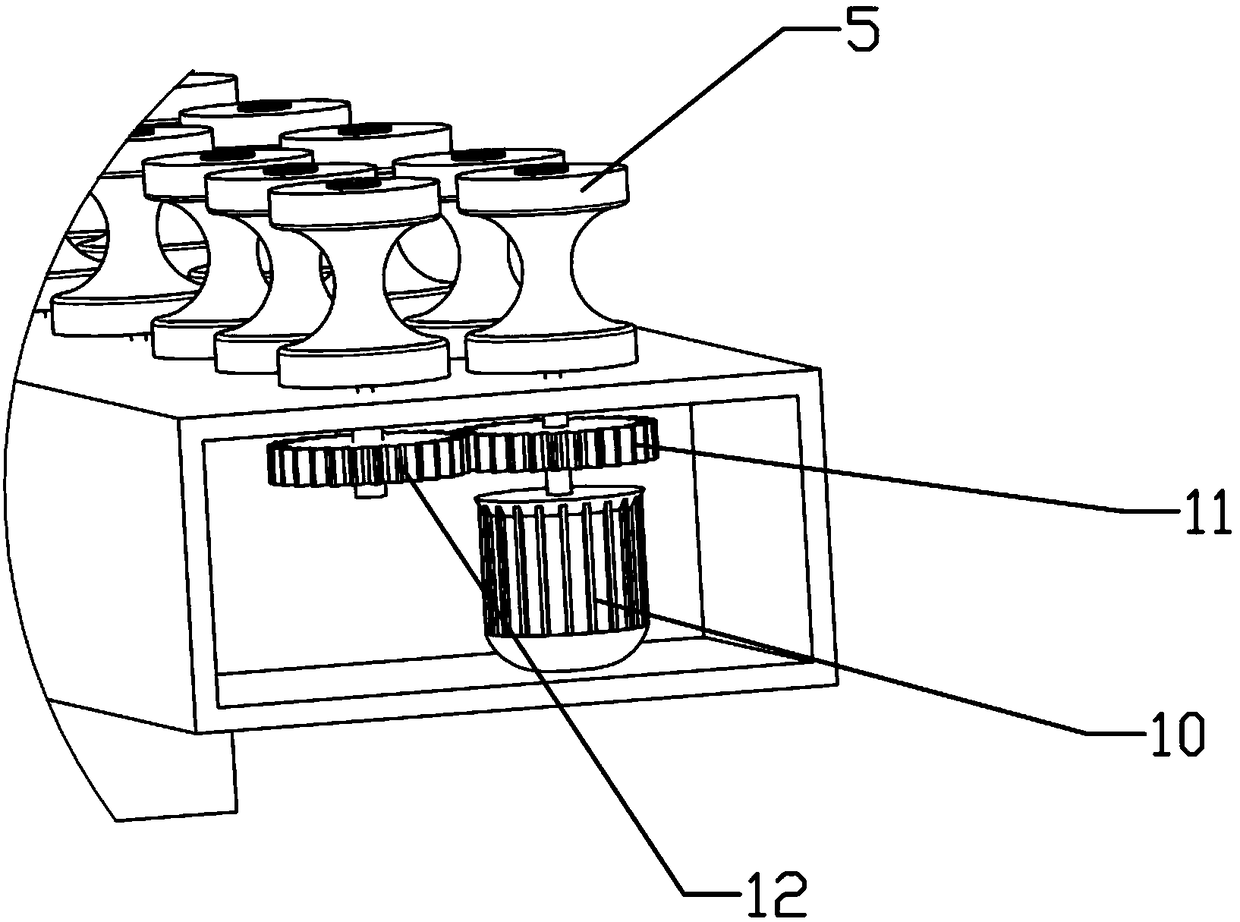

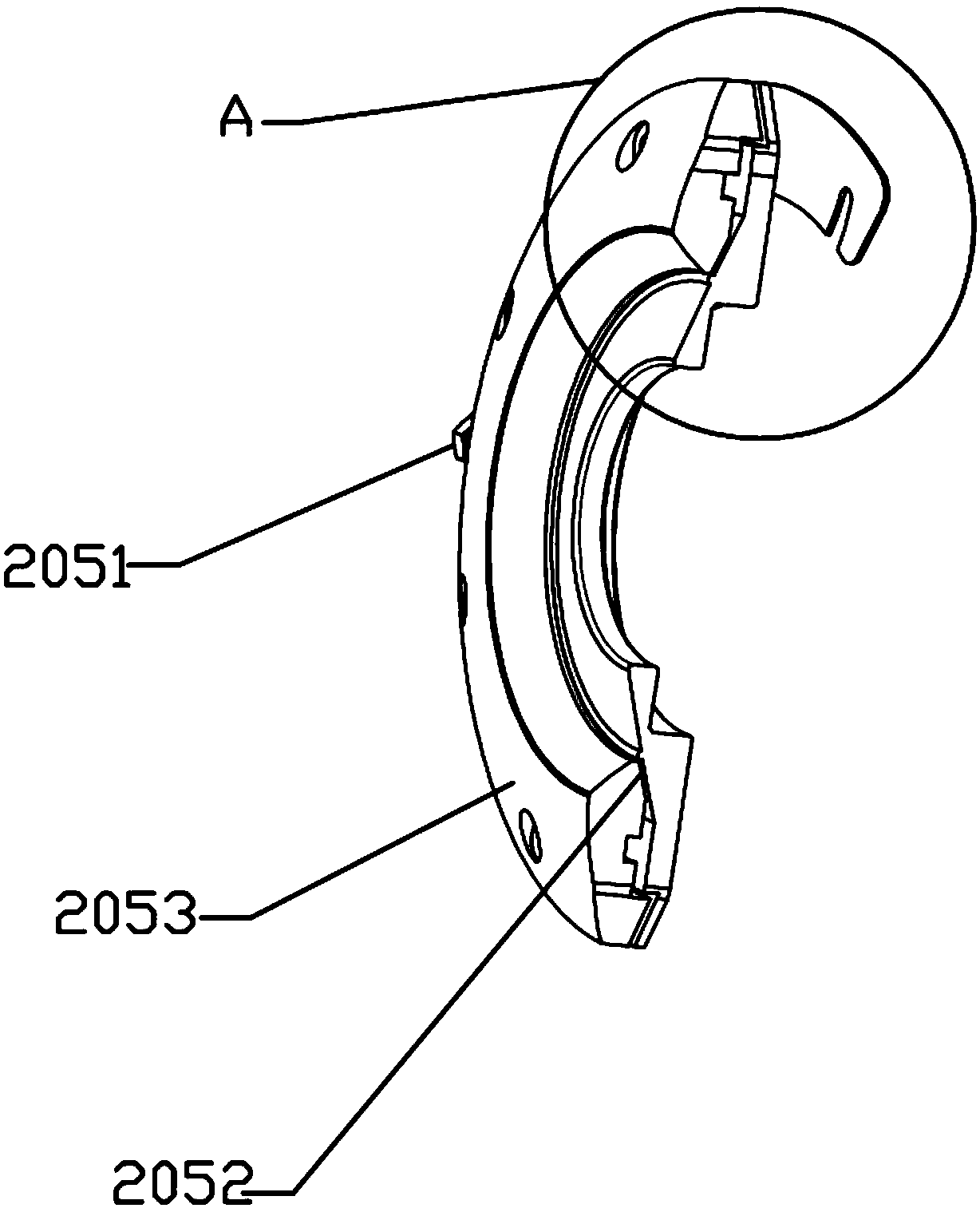

[0028] Example 1: Please also see Figure 1 to Figure 3 and Figure 6Embodiment 1 of the present invention provides a special spraying equipment for silicone rubber wire and cable, including a straightening mechanism 1, a spraying mechanism 2, an air-drying mechanism 3 and a winding mechanism 4; the straightening mechanism 1 includes a straightener body 101 and a Wire slot 102, two rows of straightening wheels 5 are arranged on the straightener body 101, the central axis of each row of straightening wheels 5 is located in the same plane, and each of the straightening wheels 5 and the straightening wheel The straightener body 101 is connected in rotation, and the straightening wheel 5 straightens the wires and cables to be sprayed to make the surface smoother, thereby ensuring more uniform spraying; the wire release trough 102 is fixedly installed on the straightening mechanism 1; The spraying mechanism 2 includes an oil storage tank 201, an atomizer 202, an air pump 203, an i...

Embodiment 2

[0032] Embodiment 2: The difference with Embodiment 1 is that, as Figure 4 and Figure 5 As shown, the spraying mechanism 2 is provided with a protective cover 13 , and the protective cover 13 is placed between the straightening mechanism 1 and the air-drying mechanism 3 . Further, the protective cover 13 includes a base 131 and a baffle 132, the baffle 132 is arc-shaped, and one end of the baffle 132 is hinged to the base 131; the upper cover 1311 of the base 131 is circular Arc-shaped, the upper cover 1311 is set corresponding to the baffle 132 , the sample injection tube 7 passes through the upper cover 1311 , and the upper cover 1311 is provided with a plurality of leakage holes 1312 . The protective cover 13 can prevent the oil mist sprayed from the annular nozzle 25 from splashing and polluting the air and endangering human health; at the same time, the excess oil mist is blocked by the baffle plate 132, flows into the leakage hole 1312 after condensation, and can coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com