Microchannel plate-based modulated X-ray generation device and method

A technology of micro-channel plate and generating device, which is applied in aerospace and precision opto-mechanical fields, can solve the problems of short lifespan of photocathode, cannot be exposed to air, cannot be replaced, etc., achieves uniform photon flow density, uniform electron density, and improves service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

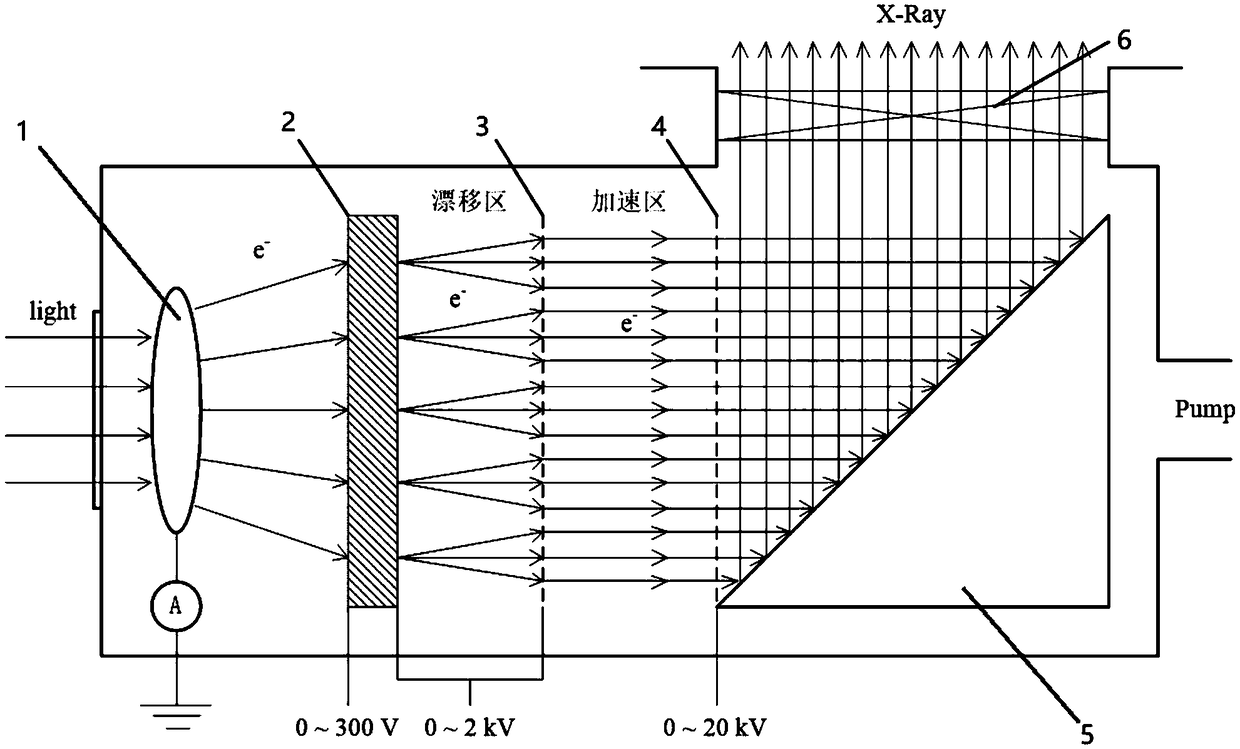

[0030] The present invention provides a kind of adjustable X-ray generation device based on microchannel plate, and this generation device comprises photocathode 1, microchannel plate 2, grid electrode, anode target 5, vacuum system and high-voltage power supply, such as figure 1 shown.

[0031] Photocathode 1: A multi-alkali photocathode is used to generate modulated photoelectrons. The quantum efficiency of this material is extremely high, and the time response is extremely fast, which can meet the requirements of a modulatable X-ray analog source.

[0032] Microchannel plate 2: an electron multiplier with a large area array. The inner wall of each channel of the microchannel plate 2 is coated with a semiconductor material that can emit secondary electrons. When a certain voltage is applied to the microchannel plate 2 After that, a uniform electric fiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com