Preparation device for oyster fermented beverage

A fermented beverage and preparation device technology, applied in the field of oyster fermented beverage preparation device, can solve the problems of insufficient equipment functions, low utilization rate of oysters, small market share, etc., achieve easy control of fermentation conditions, increase flavor and taste, The effect of little external interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

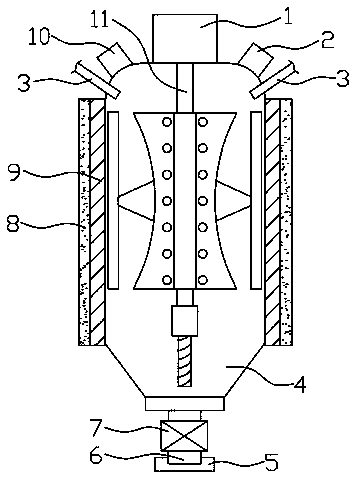

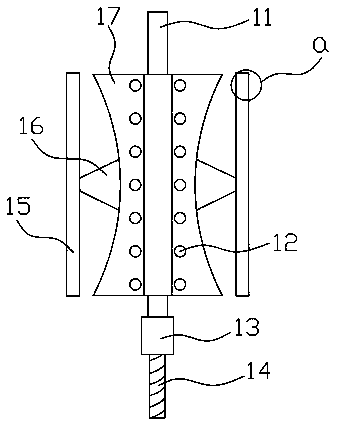

[0024] Such as Figure 1~4 As shown, the oyster fermented beverage preparation device includes a cavity 4 connected with a stirring device inside, a motor 1 connected to the stirring device is provided at the top center of the cavity 4, and the surfaces of the cavity 4 on both sides of the motor 1 are respectively connected with feeding ports 10 and the feeding port 2, the lower end of the cavity 4 is funnel-shaped, the bottom of the cavity 4 is connected with a discharge port 6, the surface of the discharge port 6 is connected with a solenoid valve 7, the stirring device includes a stirring rod 11 connected with the output shaft of the motor 1, An electric telescopic rod 13 is connected to the bottom of the stirring rod 11, and a screw rod 14 is connected to the bottom of the electric telescopic rod 13. Cavity 4 is the main place for fermentation. Fermentation in cavity 4 is subject to little external interference, and the fermentation conditions are easy to control, which is...

Embodiment 2

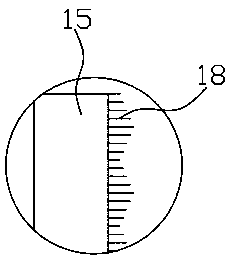

[0032] Such as Figure 5 As shown, the outer edge of the inner plate 17 is an arc edge recessed inward, and the plate surface of the inner plate 17 is provided with a through hole 12, and the inside of the through hole 12 is equidistantly connected with a cross-shaped elastic rope 19, and the intersection of the elastic rope 19 A glass bulb 20 is attached. The inward recess of the outer edge of the inner plate 17 can enhance the gathering force of the reactants when the inner plate 17 is stirred, so that the reactants on the upper and lower sides continuously roll to the inside, avoiding the stirring dead angle of the stirring device, and the through hole 12 can reduce the The resistance on the surface of the inner plate 17 reduces unnecessary energy consumption of the stirring device. The elastic rope 19 connected inside the through hole 12 makes the material passing through the through hole 12 subject to multiple impacts and frictions. The glass ball 20 can increase the elas...

Embodiment 3

[0036] The working principle of the present invention is: spray hot water from the water spray pipe 3 into the interior of the cavity 4, and sterilize the interior of the cavity 4 before fermentation. Close the discharge port 6 after discharge, start the heating layer 9 to make the internal temperature of the cavity 4 gradually rise to a suitable temperature for the strain, and then cooperate with the insulation layer 8 to maintain the internal temperature of the cavity 4 at a suitable temperature, and the treated oyster liquid The substrate is injected into the cavity from the feed port 10, and the injection is stopped after the liquid reaches 85% of the volume of the cavity 4, and the bacteria are added from the feed port 2, and the motor 1 controls the stirring device to run for 5 minutes and stop for 20 minutes. Stirring is carried out so that the material inside the cavity 4 can be fully stirred evenly, and has a suitable static reaction time, which effectively improves th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com